3DPlatform.com

19

Care & Maintenance

Cleaning the Nozzle

Use extreme caution when maintaining or operating

heated machinery. The nozzle must be heated to 180ºC

(minimum) when cleaning.

When to clean the nozzle:

• When filament is not flowing smoothly

• When filament is not being extruded appropriately

• When changing material type

• Periodically between large prints—preventative

maintenance

How to clean the nozzle:

• Cold-pull method:

– With filament in the hot end, heat nozzle to

printing temperature according to the filament

– Cool nozzle to 90ºC

– Immediately after 90ºC temperature is reached,

press button on side of extruder, quickly pull

filament from extruder

– Examine end of filament that was in extruder to

see if there are any visible artifacts

Changing the Nozzle

1. To replace the nozzle on the extruder head, first send

the extruder to the home location.

2. Once the extruder is at the home position, raise the

Z axis by 220 mm. This will give room to work under

the extruder head.

Tools Required

• 7 mm Wrench or Socket Wrench

• Crescent Wrench

Safety Guidelines

• Wear heat resistant gloves.

• Prior to all routine maintenance on the extruder

and/or nozzle, insert 6-inch tall block under

actuator to avoid any type of crush hazard.

• Use appropriate tools for all cleaning

and maintenance.

3. Set the extruder nozzle temperature to 200ºC. This

will melt any plastic inside the extruder and loosen

the nozzle.

4. Once the temperature has reached 200ºC,

use a crescent wrench and 7-mm wrench to

remove the nozzle. Use the crescent wrench to hold

the base steady. Use caution—nozzle is hot!

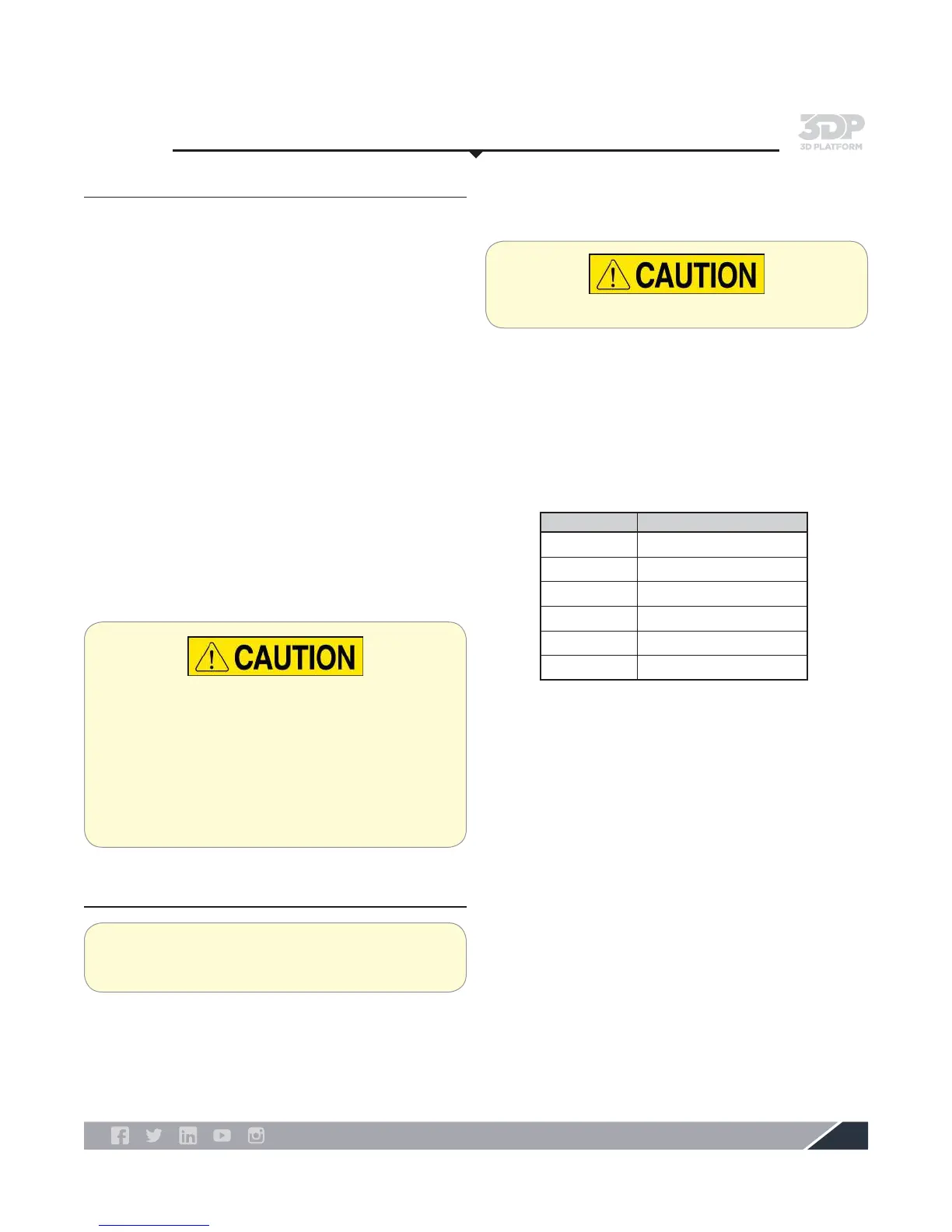

5. Once nozzle is removed select the replacement

nozzle. Nozzle size can be determined by inspecting

the machined dots along the side of the nozzle. Refer

to the table below for sizes.

6. Once new nozzle has been selected, hand thread it

into the extruder.

7. Then use the wrench and crescent wrench to tighten

the nozzle into the assembly. Tighten until snug. DO

NOT OVER TIGHTEN.

8. Once nozzle is tightened, set the extruder

temperature from 200ºC to 280ºC. This will heat up

the nozzle and ensure it has a tight fit. Make sure

the extruder fan is turned off or the extruder will not

reach the desired temperature.

9. Once the temperature has reached 280ºC, use the

wrench and crescent wrench to tighten. The torque

specification for final tightening of the nozzle should

be 3 Nm or 26.55 in/lbs.

ID DOTS NOZZLE SIZE

0 0.6 mm

1 0.8 mm

2 1.00 mm

3 1.2 mm

4 0.4 mm

5 N/A

Do not touch heated nozzle.

Loading...

Loading...