3DPlatform.com

24

Printing Tips

Orienting the part for success

Part orientation—the direction the part is positioned on

the print bed—effects the print quality, print time, surface

finish, and overall print-ability of the model. The following

tips are intended to assist in orienting your part for a

successful print:

• Position so the most surface area is in level contact

with the print bed

• If possible, orient the part to reduce or eliminate

support structures

• Consider surface finish and position the part

accordingly

• Reduce support structures to reduce print time

• Use a raft to avoid adhesion problems when break-

away support structures are used directly on the

print bed

Link to article: Perfecting the First Layer

Good First Layer

The first layer may be the most important layer of any

print—and perhaps the most difficult. A good first layer is

vital to the success of your print.

Qualities of a good first layer include:

• Clean (clear of debris), prepared glass

• Proper bed temperature

• Optimal first layer nozzle height (

Z-Gap, page 23)

A good first layer adheres to the print bed, is the correct

distance from the print bed and is visibly smooth and

level without gaps or bumps.

Here are a few tips for getting a good first layer:

• Make sure the print bed is level

• Clean and clear any debris from the print bed and

prepare the glass for printing (Prepare the

Print Bed, page 18)

• Getting the first layer height dialed in is critical

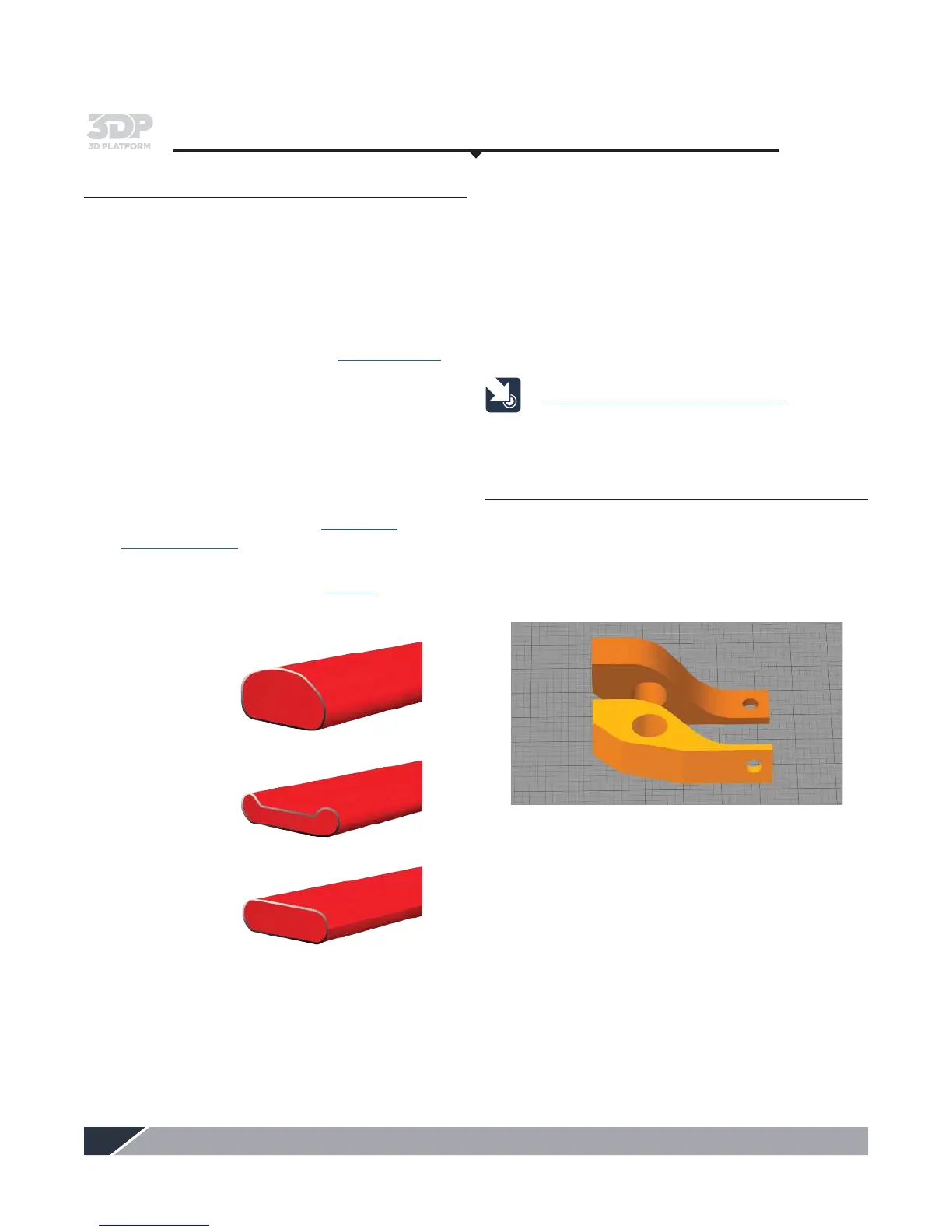

See graphic below. Reference page 23.

– If the first layer is too high it will not stick

– If the first layer is too low it will create a valley,

and may drag the nozzle on the glass

– The first layer height is correct when the bead

of filament is flattened slightly and even

• Heat the print bed to the recommended

temperature; based upon the material being used

– If adhesion problems persist, increase bed

temperature to 80ºC to 85ºC

• Increase the nozzle temperature by 10ºC to 20ºC for

the first 1-3 layers to aid in adhesion

•

Decrease the printing speed by 30% for the first layer

• Print a test print to ensure good first layer adhesion

First layer height too high

First layer height too low

First layer height correct

Loading...

Loading...