44

087-0020 REV E

STEP 6 – Set the voltage calibrator to input 0.550 mV.

Using the magnetic tip of the screwdriver, touch the magnet to the “S” span

point on the transmitter body and hold it there. After four seconds the bar

graph will disappear and the reading will begin to flash. Adjust the UP or

Down buttons with the magnet until full scale (100ppm) is indicated. Hit the

“S” – Enter spot and the word “Set” will momentarily be shown.

Remove the magnet. The display should read full-scale (100ppm) and the

DVM should read 200 mV.

If sensor simulation indicates that the transmitter is functioning properly, the problem

does not reside with the transmitter electronics. Check the elastomeric pad, sensor, and

calibration source & or technique.

Zero Drift and False Alarms

If “zero drift” (unexplained output when the target gas is not present) is noted, the

problem could be the presence of an interferent gas. This is particularly true if the sensor

is a low range oxidant gas type (e.g., chlorine, ozone, etc.) in the low PPM full scale

range. It is not uncommon for background atmospheric ozone, for example, to be

present on sunny days in concentration ranges of up to and exceeding 140 PPB.

If you notice a regular increase in output on dry, sunny afternoons you should contact

your clean air monitoring office to see if high ozone levels are present. When trying to

detect gases at less than 1 PPM (1000 PPB) concentration levels, many interferences

may be present – particularly if close to an active industrial environment.

Poor Electrical Connection

Possible Problem – Elastomeric Connector

Good electrical connection between the sensor and the transmitter is dependent upon

the elastomeric connector. If both the original sensor and the simulator produce an

intermittent output or no output at all, the problem may be the elastomeric connector.

Test to ensure that the threaded end cap is not loose. Also, the connector may have

become damaged due to ingress of dirt or exposure to a corrosive atmosphere.

In these cases replace the elastomeric connector.

Fault Codes and Error Messages

When the transmitter detects a fault, the error code F0# appears on the display.

The current loop output will go to the programmed fault level (3.1 mA ), unless the

transmitter is in inhibit mode (also visible on the display).

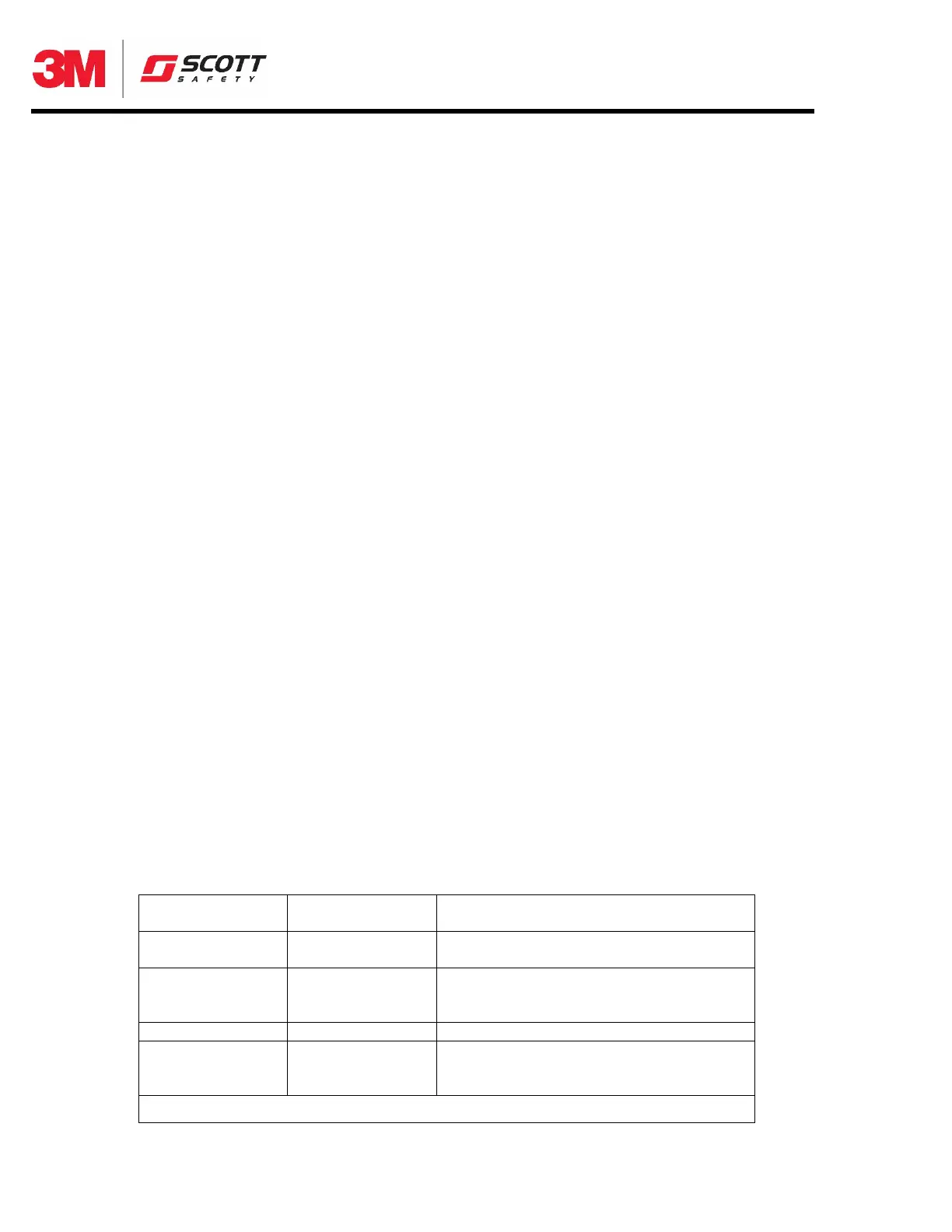

FAULT CODE

DISPLAY

MESSAGE POSSIBLE CORRECTIVE ACTION

F01 Loop Cal Failure Recheck Accuracy Of Calibration Gas

Replace Sensor & Or Elastomeric Pad

F02 SST Failure

(Sensor Self Test )

Verify the SST is operating properly

Verify wind speed is less than 22 MPH

Replace Sensor & Or Elastomeric Pad

F04 Future Use

F08 Missing Sensor

Indicator

Re-seat Sensor

Tighten Down On End Cap

Replace Elastomeric Pad

Required Procedure After Replacing Equipment

Freedom 5000 Universal Analog Toxic Gas Detector

Instruction Manual

Loading...

Loading...