7

Servicing should only be performed by a Qualied Service Technician

GAS PIPING

Contact your local gas service company to ensure that adequate gas service is available and to review

applicable installation codes for your area.

Size the main gas line in accordance with Table below. The gures shown are for straight lengths of pipe

at 0.5 in. W.C. pressure drop, which is considered normal for low pressure systems. Note: Fittings such as

elbows, tees and line regulators will add to the pipe pressure drop. Also refer to the latest version of the

National Fuel Gas Code.

Schedule 40 Steel or Wrought Iron Pipe is the preferred material for the gas line of this water heater. It

is imperative to follow the sizing recommendations in the latest version of the National Fuel Gas Code if

Corrugated Stainless Steel Tubing (CSST) is used as the gas line for this water heater.

The heater is not intended for operation at higher than 14.0" W.C.- natural gas, (1/2 pound per square inch

gage) supply gas pressure. Exposure to higher supply pressure may cause damage to the gas valve which

could result in re or explosion. If overpressure has occurred such as through improper testing of gas lines or

emergency malfunction of the supply system, the gas valve must be checked for safe operation. Make sure

that the outside vents on the supply regulators and the safety vent valves are protected against blockage.

These are parts of the gas supply system, not the heater. Vent blockage may occur during ice storms.

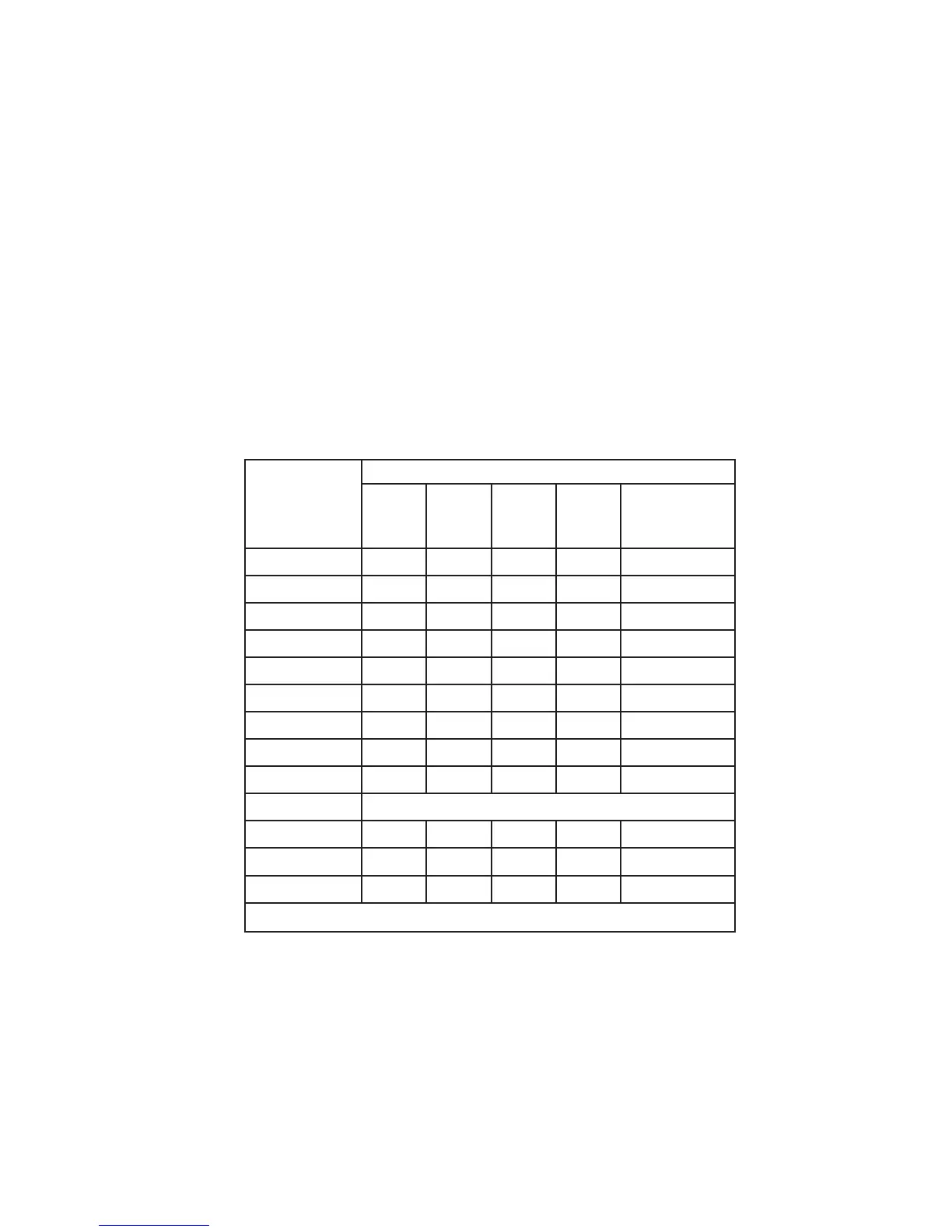

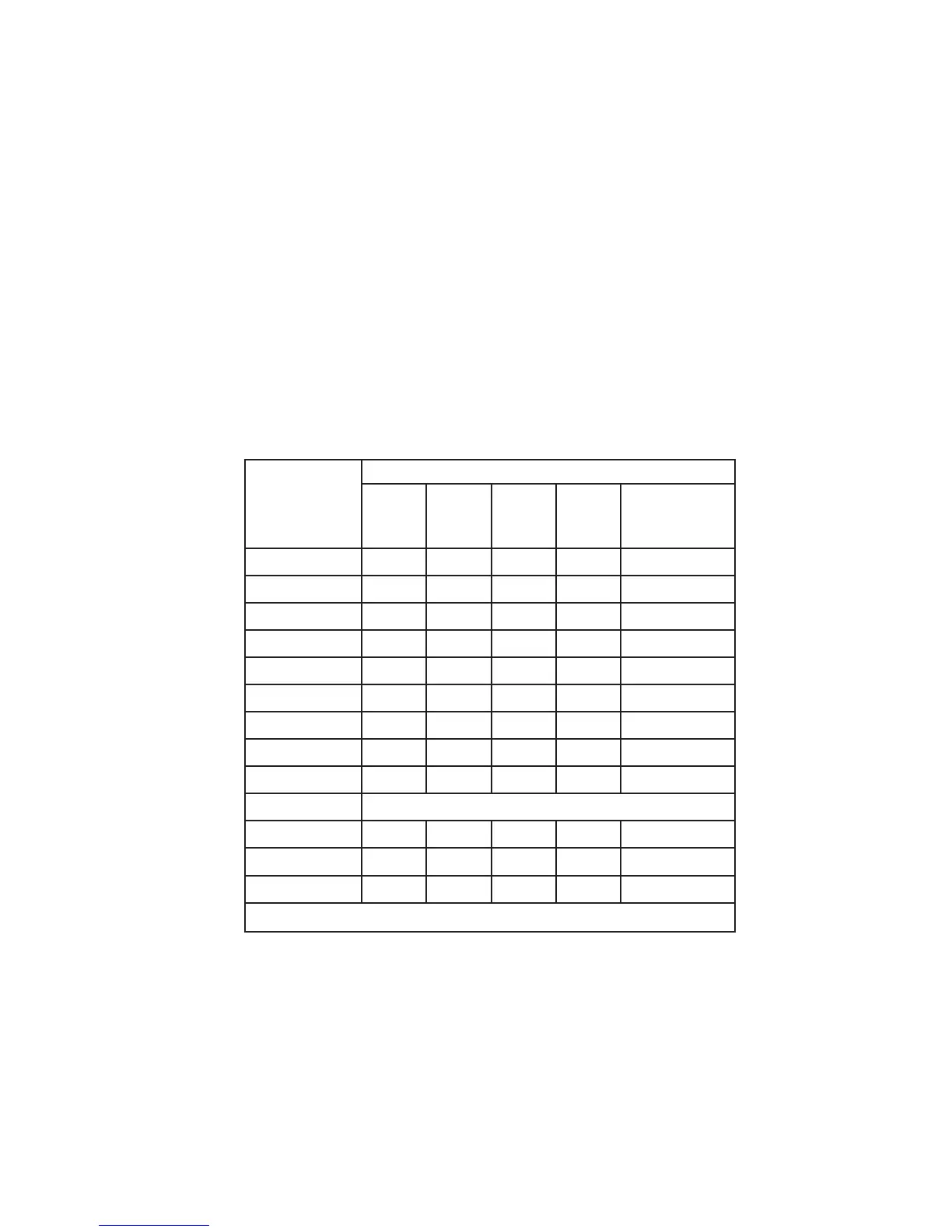

GAS SUPPLY PIPE LENGTHS (IN FEET)

Maximum Equivalent Pipe Length - Natural Gas Only

Input rate

(BTU/HR)

Schedule 40 Steel or Wrought Iron Pipe

1/2" 3/4" 1" 1 1/4" 1 1/2"

120,000 20 70 200 200 200

154,000 10 40 150 200 200

180,000 - 30 100 200 200

199,000 - 30 90 200 200

250,000 - 20 60 200 200

275,000 - 10 50 200 200

310,000 - 10 40 150 200

366,000 - - 30 100 200

390,000 - - 20 100 200

Fitting Type* Equivalent length in feet

45°Ell 0.7 1.0 1.2 1.6 1.9

90°Ell 1.6 2.1 2.6 3.5 4.0

Tee 3.1 4.1 5.2 6.9 8.0

Natural Gas 0.60 Specic Gravity, 0.50" W.C. Pressure Drop

*Screwed Fittings

It is important to guard against gas valve fouling from contaminants in gas ways. Such fouling may cause

improper operation, re or explosion.

If copper supply lines are used they must be internally tinned and certied for gas service. Before attaching

the gas line, be sure that all gas pipe is clean on the inside. The instructions in this section on venting must

be followed to avoid choked combustion or recirculation of ue gases. Such conditions cause sooting or risks

of re and asphyxiation.

Loading...

Loading...