Conguring the Controller

Conguration

Binary Input #7

In Figure 23 Item #1 it indicates that Binary Input #7 (BIN7) is not used

in this typical Central Plant Controller conguration. Your application

may require its use and it can be congured as needed.

Binary Input #8

In this example this is the input conguration screen for the Emergency

Shut Down (“Emerg Shut Down”) Binary Input #8 (BIN8). Item #1

in Figure 24 indicates the “Emerg Shut Down” input is congured for

a normally closed contact. This would typically be a contact from a

safety device such as a smoke detector or re stat. When this contact

is activated it would open causing an emergency sequence to initiate.

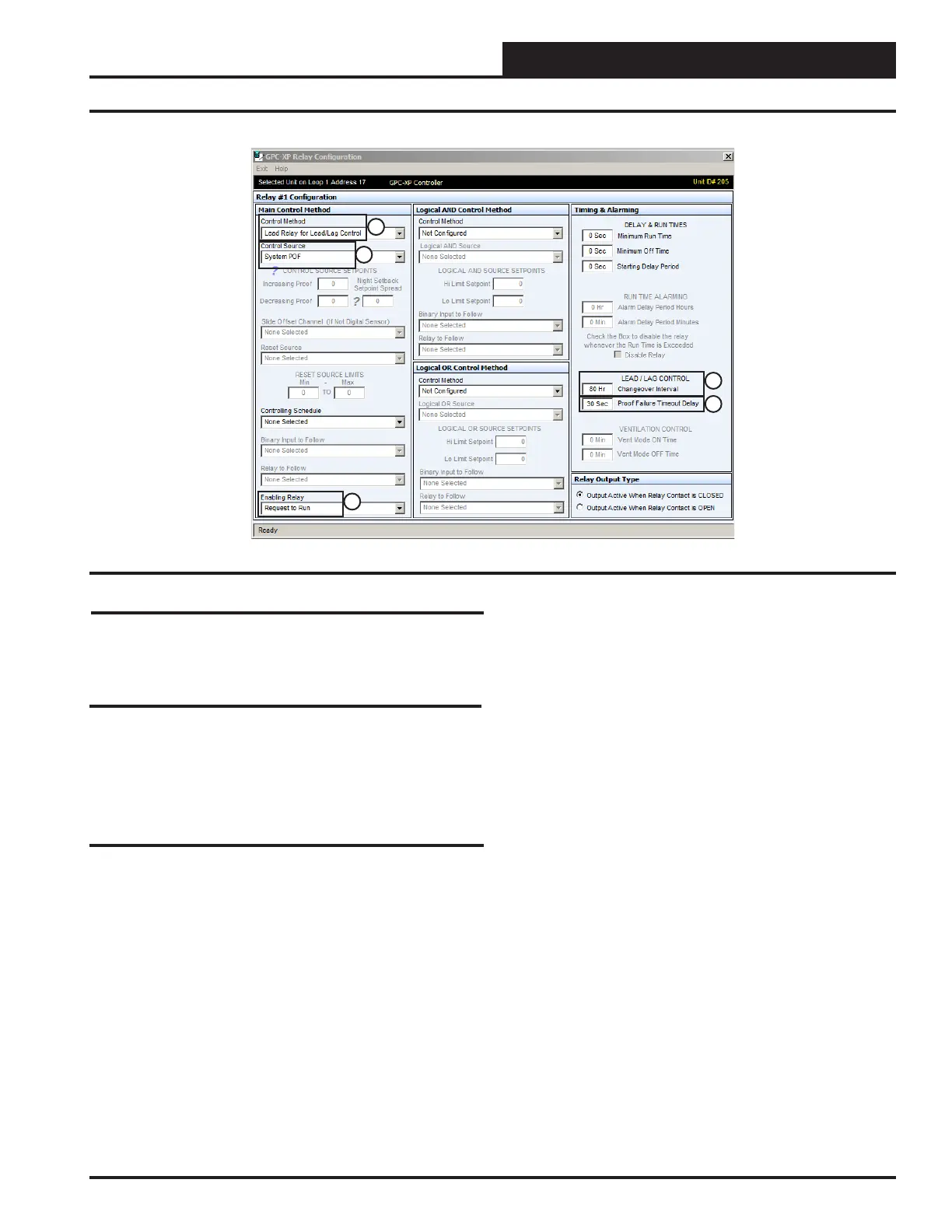

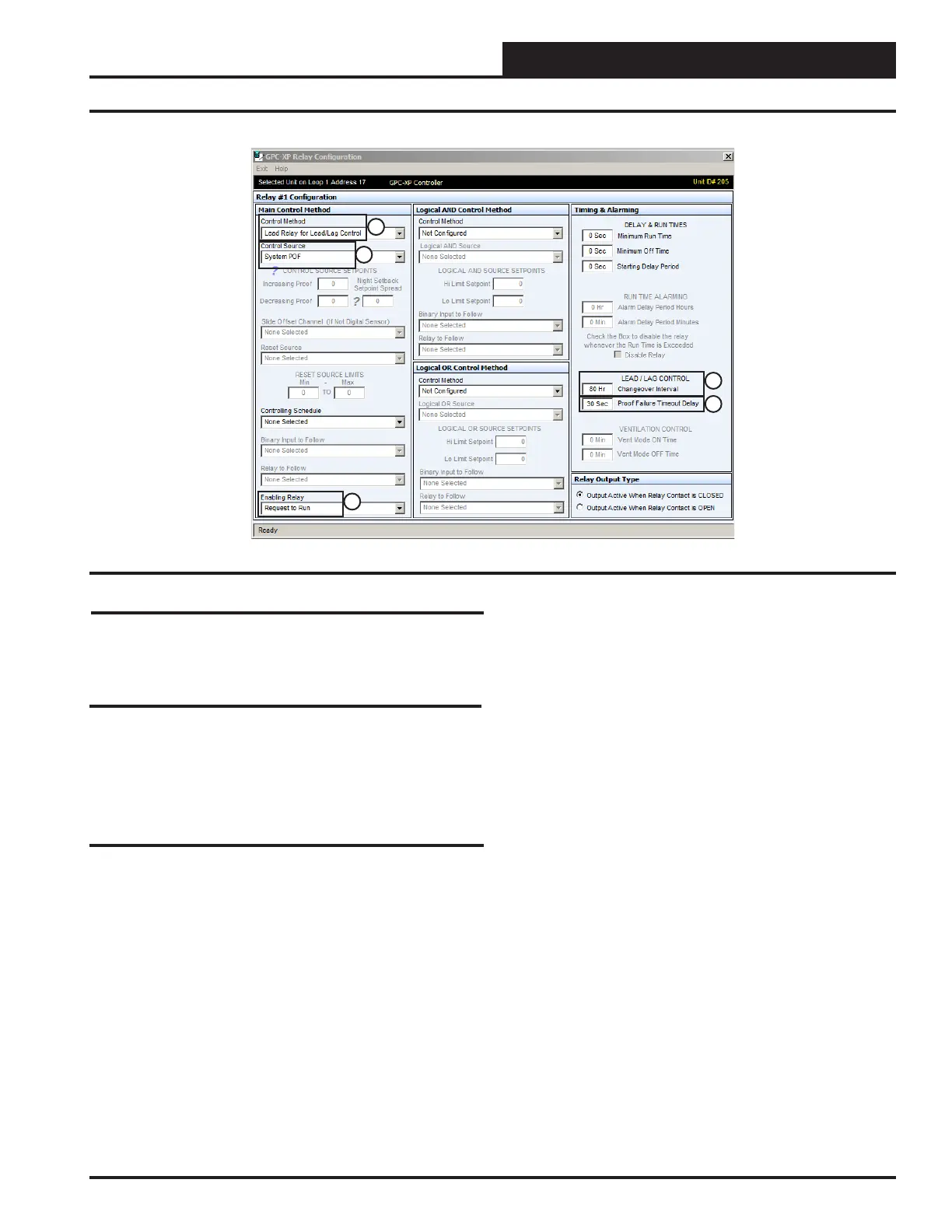

Relay Output #1

In this example Relay Output #1 is congured for “System Pump 1”. In

Figure 25 Item #1 it indicates it has a Main Control Method of “Lead

Relay for Lead/Lag Control”. This means it is the “Lead Pump Relay”

for Lead/Lag type system pump control.

Item #2 indicates the Control Source for this relay will be the “Proof

Of Flow” switch (BIN3). The System Pump is congured with a 30

second Proof Failure Timeout Delay shown in Item #5. This means the

pump Relay Output #1 will activate and “System Pump 1” will have 30

seconds to bring the system water pressure to the setting required, for

the “Proof Of Flow” binary input to be activated. If after that time the

P.O.F. switch doesn’t activate Relay Output #1 will be deactivated and

Relay Output #2 (System Pump 2) will be activated.

It also has a Enabling Relay of “Request To Run” as shown in Item #3.

The “Request To Run relay output is congured on Relay #7.

Item #4 is the “Changeover Interval” for the Lead/Lag Pump sequence.

In this example it has been congured to switch from “System Pump 1”

(Lead) to “System Pump 2” (Lag) after 80 hours of runtime on “System

Pump 1”. Item #5 is the “Proof Failure Time Out Delay”. This is set

for the amount of time that you want the pump to run before a failure

of the “Proof of Flow” binary input shuts down the pump. In this case

it is set to 30 seconds.

With this conguration sequence “System Pump 1” (Relay #1) or “Sys-

tem Pump 2” (Relay #2) will activate when the “System P.O.F.” switch

(BIN3) is activated and the “Request To Run” relay output (Relay #7)

is active.

If the “Request To Run” relay output (Relay #7) is inactive (Relay #1)

will deactivate, turning off “System Pump 1” (or “System Pump 2” if

it is running instead).

If either System Pump 1 or 2 has a Proof Of Flow failure when the

specied pump is supposed to run, an alarm will become active for that

system pump.

To reset a Lead/Lag failure alarm, click on the ALARM button in the

upper right hand corner of GPC-XP Status Screen. When the GPC-XP

Alarms Screen comes up, click on the “Reset Lead/Lag” button, then

exit the screen. The alarm will clear and, the pump with the least amount

of run time will start.

All the settings above will be automatically be applied to the “System

Pump 2” on Relay Output #4 after the “Changeover Interval” for “System

Pump 1 has occurred or System Pump 1 has a “System P.O.F” failure.

Figure 25: Relay Output #1 Screen

1

2

3

4

5

25

WSHP Loop Controller GPC-XP Guide

Loading...

Loading...