8

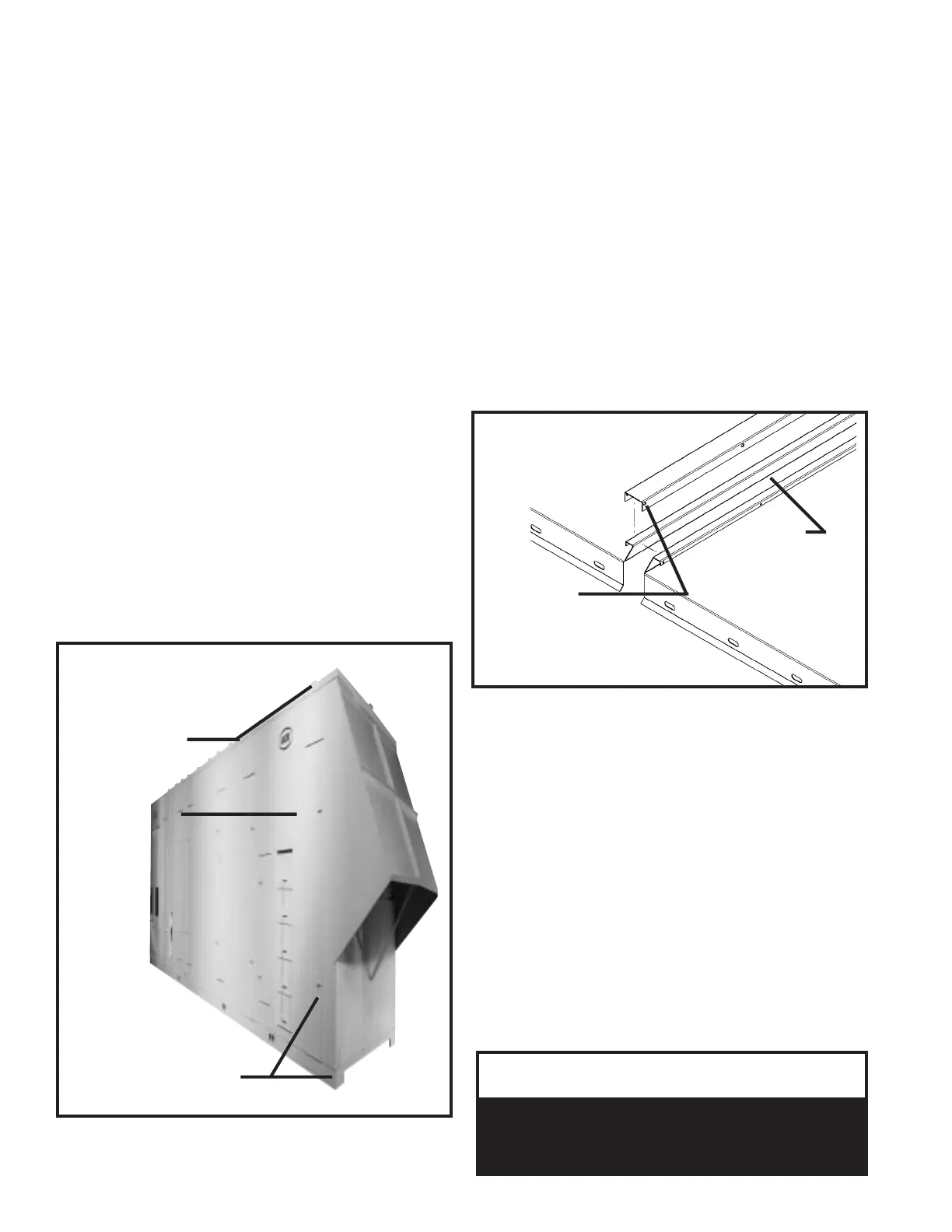

Unit Section Splicing

AAON ‘RL’ units are designed and built according to unit

size and / or job specifications. Some applications may

require the unit to be built and shipped in two separate

sections. The following illustrations are provided as

practical guidelines for splicing the two sections.

It is recommended to lift and set the largest section first,

checking for the correct location and position. In order to

simplify the connection of the two sections, it is impor-

tant, once the first section is in place, to position and set

the second section AS CLOSE AS POSSIBLE to the first

section. The least amount of travel between the two

sections will allow the use of a “come-a-long” tool, (one on

each side of the unit, connected at the base slots) to

equally pull the second section against the first section.

The two sections must be tightly adjoined before the

splicing parts can be installed.

Because the adjoining section is “unit specific”, all parts

required for splicing the sections together are provided

from the factory.

Once the unit is completely assembled, it is important to

visually inspect all exposed areas and fill any gaps with

Butyl caulking.

NOTE: Installation of splice plates are typical for both

sides of unit.

INSTALLATION continued

During the splicing process it is equally important to

check the alignment of the roof and the connecting

flange. Prior to connecting the sections, to create a water

tight seal, Butyl caulking must be applied between the

two roof flange sections.

The roof splice cap is provided from the factory and must

be installed over the two sections connecting flange and

secured with screws along the length of the cap.

NOTE: ATTACH SPLICE CAP WITH SCREWS FROM

EACH SIDE OF THE CAP ONLY.

DO NOT INSTALL SCREWS FROM THE TOP.

Once the splice cap is secured into place, Butyl caulking

must be used to seal the perimeter of the cap against the

roof of the unit.

IMPORTANT

RELATED ELECTRICAL REQUIREMENTS

Before attempting to make wire connections from section

to section it is important to refer to the specific wiring

diagram located in the unit controls compartment to

obtain additional details related to the wiring of the unit.

The adjoining section is factory wired and ready for field

connection. The electrical wiring is unit specific and

designed according to the overall unit configuration.

A factory supplied and mounted terminal block is located

in the main section of the unit that must be used in

making the rough-in wire connections.

Each wire being spliced from section to section is tagged

at both ends according to its termination. Note that

junctions for wiring the sections together are separated

according to voltage.

▲

All wire terminations MUST BE made before

applying power to the unit. The unit will not

operate unless all circuits are made.

!

CAUTION

UNIT BASE AND SIDES

STEP 1:

ALIGN BASE RAIL

& SIDES OF SECTIONS

- TYPICAL TWO SIDES -

NOTE: FACTORY INSTALLED

NEOPRENE GASKET APPLIED

ON ENDS OF BOTH SECTIONS

STEP 3:

FILL POST SEAM WITH

BUTYL CAULKING

STEP 4:

ATTACH SPLICE PLATE

TO OUTSIDE OF POST

(screws provided)

TO COVER SEAM

STEP 5:

APPLY BUTYL CAULKING

TO ALL SEAMS

& PERIMETER OF SPLICE

STEP 2:

CHECK ROOF ALIGNMENT

(see detail)

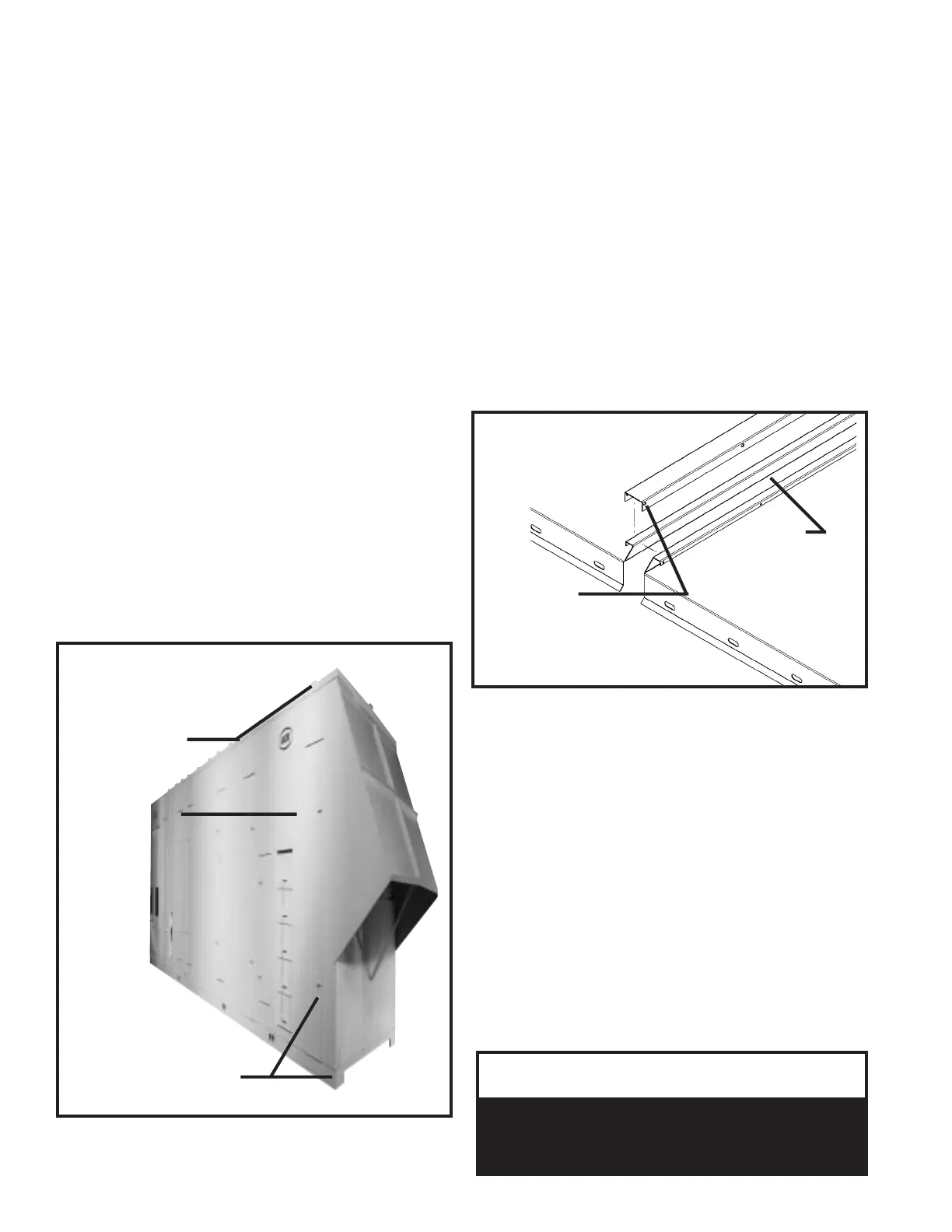

UNIT ROOF FLANGE SPLICE DETAIL

STEP 1:

APPLY BUTYL

CAULKING BETWEEN

SECTIONS OF ROOF FLANGE

- MUST BE A

WATER TIGHT SEAL -

STEP 2:

SET ROOF SPLICE IN

PLACE OVER FLANGE

SECURE WITH SCREWS

FROM THE SIDES.

SEAL PERIMETER WITH

BUTYL CAULKING

NOTE:

DO NOT INSTALL

SCREWS FROM THE

TOP OF SPLICE CAP.

Loading...

Loading...