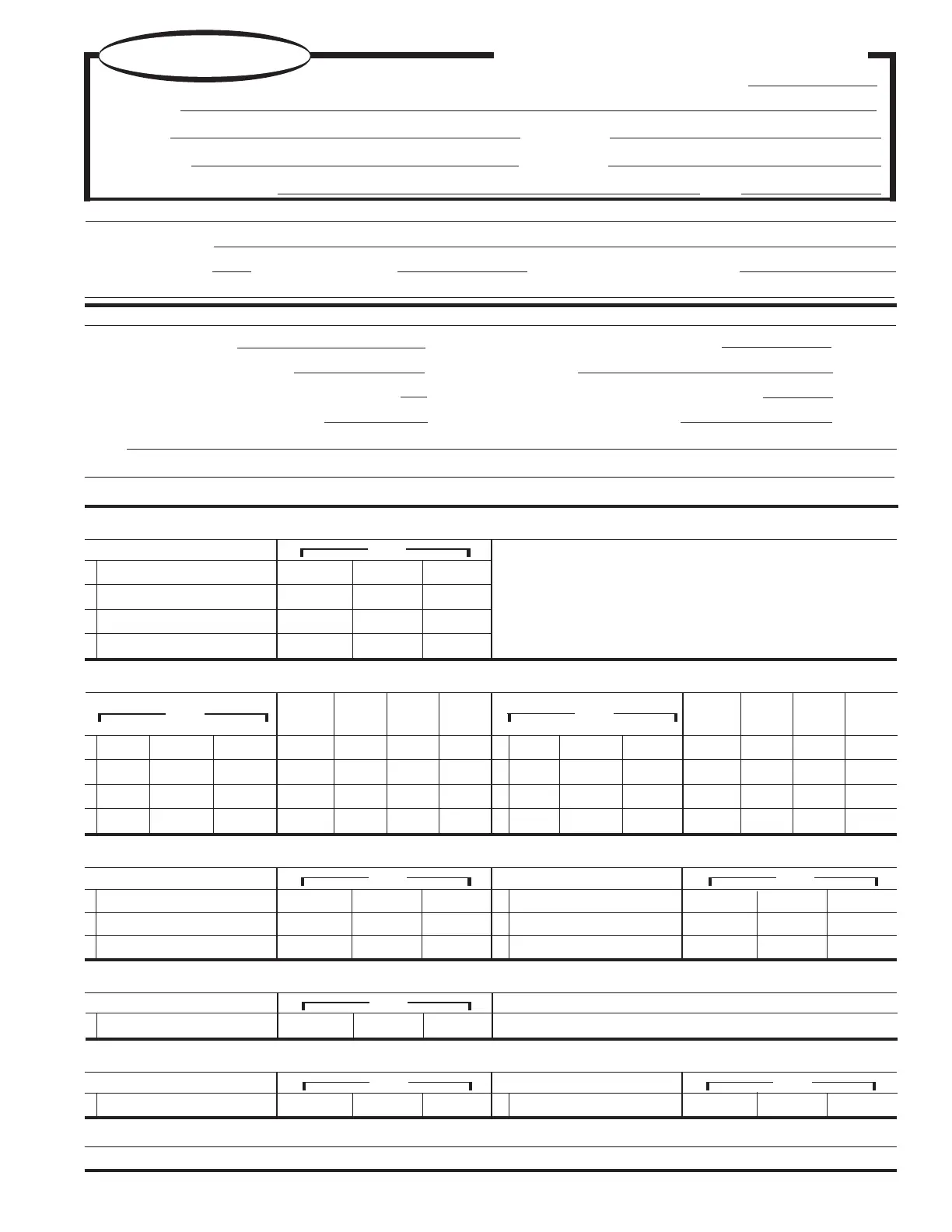

33

JOB NAME:

ADDRESS:

CITY, STATE:

RL START-UP FORM • Page 1 of 2

Inspect Unit For Damage: ❏

Check All Fans For Free Movement: ❏

Verify All Copper Tubing Is Isolated So It Doesn't Rub: ❏

Check & Tighten All Electrical Terminals: ❏

Notes:

START-UP CONTRACTOR:

SERIAL No:

MODEL No:

DATE:

START-UP CHECK LIST • GENERAL CHECKS

TAG:

AAON

®

AIR COOLED ❏

EVAP. COOLED ❏ NO WATER LEAKS ❏ CONDENSER SAFETY CHECK ❏

Inspect Economizer Damper Assembly: ❏

Verify Voltage: ❏

Verify Transformer Tap On 208/230v Equip.: ❏

Tighten All Set Screws On Fans: ❏

UNIT CONFIGURATION

Head

Pressure

PSIG

Crankcase

Heater

Amps

Suction

Pressure

PSIG

1

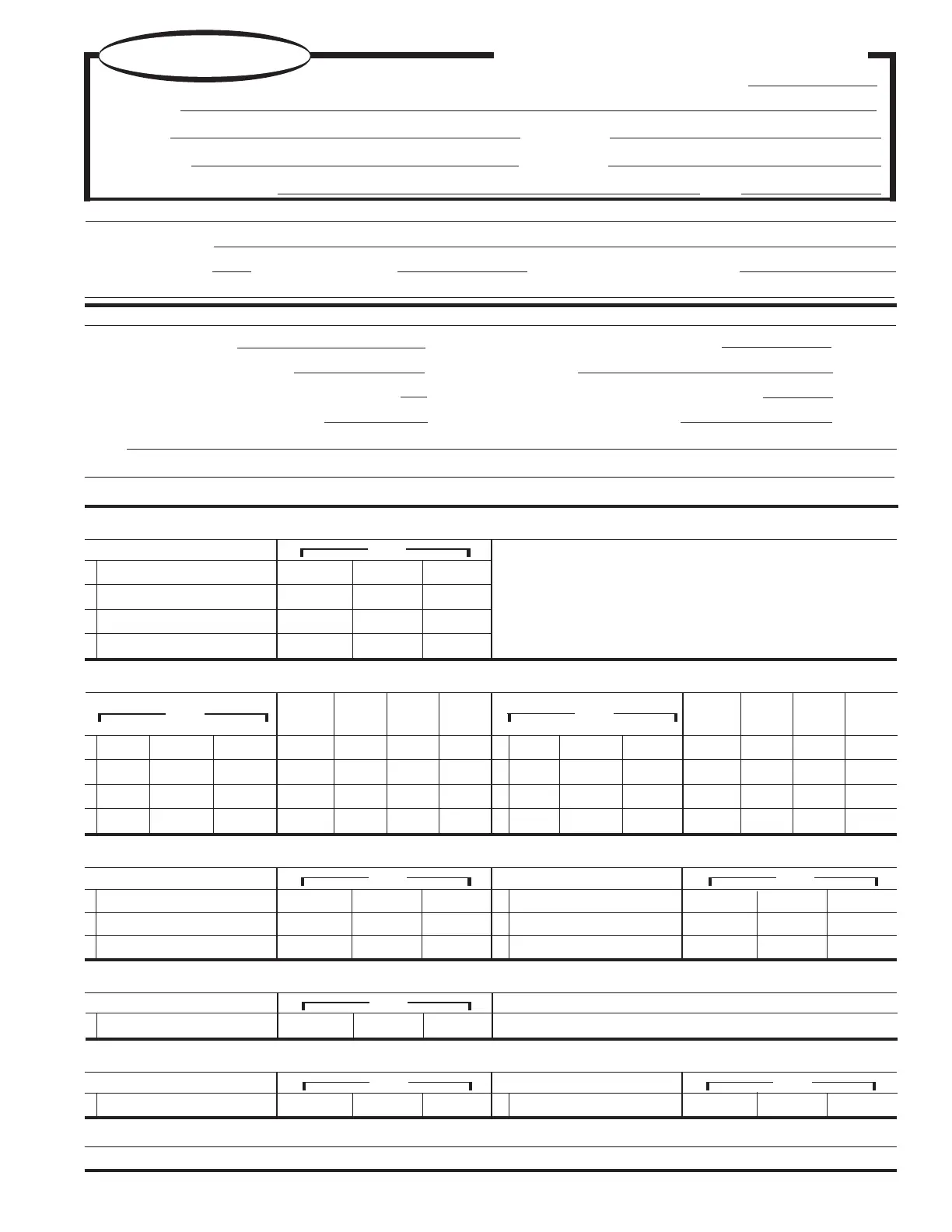

COOLING TEST

TANDEM COMPS. ❏ INDEPENDENT CIRCUITED COMPS. ❏ AMBIENT TEMP. ___________°F

High

Pressure

Switch

Head

Pressure

PSIG

Crankcase

Heater

Amps

Suction

Pressure

PSIG

High

Pressure

Switch

2

3

4

5

6

7

8

MOTOR MAKE & AMPS

1

CONDENSER FAN ASSEMBLY

ALIGNMENT ❏ CHECK ROTATION ❏ NAMEPLATE AMPS ___________

2

3

4

5

6

MOTOR MAKE & AMPS

COND. PUMP (1) - AMPS

1

CONDENSER PUMP

CHECK ROTATION ❏

MOTOR MAKE & AMPS

1

S/A BLOWER ASSEMBLY

ALIGNMENT ❏ CHECK ROTATION ❏ NAMEPLATE AMPS ___________

2

3

4

BAND SIZE ____________________________________________________

VFD DESIGN FREQUENCY ______________________________________

VAV CONTROLS _______________________________________________

SPRINGS OPERATING CORRECTLY ❏

MOTOR MAKE & AMPS

1

HEATWHEEL ASSEMBLY

CORRECT ROTATION DIRECTION ❏ WHEEL SPINS FREELY ❏ FLA __________

2

MOTOR MAKE & AMPS

3 Ø

COMP. No.& AMPS

L1 L2 L3

3 Ø

COMP. No.& AMPS

L1 L2 L3

3 Ø3 Ø

3 Ø

3 Ø 3 Ø

3 Ø

Loading...

Loading...