Assembly Instructions / A101-H

4 Installing the turbocharger / 4.4 Fastening the turbocharger with a

standard nut

© Copyright 2019 ABB. All rights reserved. HZTL455311P0038_EN Rev.A December 2019

4.4 Fastening the turbocharger with a standard nut

u Fit the nuts and tighten them according to variant 1 or 2 in the table below.

Product Through hole in

bearing casing

[mm]

Fixing screws

[mm]

Variant 1: Tightening

torques [Nm] **)

Variant 2: Hy-

draulic pre-ten-

sioning forces [kN]

A131-H Ø17 M16 280 110

A136-H Ø 21 M20 560 175

Table7: Tightening torque for standard nuts

**) When the turbocharger is mounted on the engine support, the bolt threads and screw

heads must be lightly oiled (assumed friction coefficient µ = 0.12 for tightening torque)

u Remove the lifting gear.

4.5 Connecting the turbocharger

u Connect the cable to the speed sensor (86515).

u Connect all exhaust gas, water and air lines according to the instructions of the engineb-

uilder.

Version with compressor wheel cooling

CAUTION

Failure of compressor wheel cooling

Any prolonged failure of the compressor wheel cooling will shorten the re-

placement interval of the compressor wheel.

u Make sure there is an uninterrupted supply of cooling air during opera-

tion.

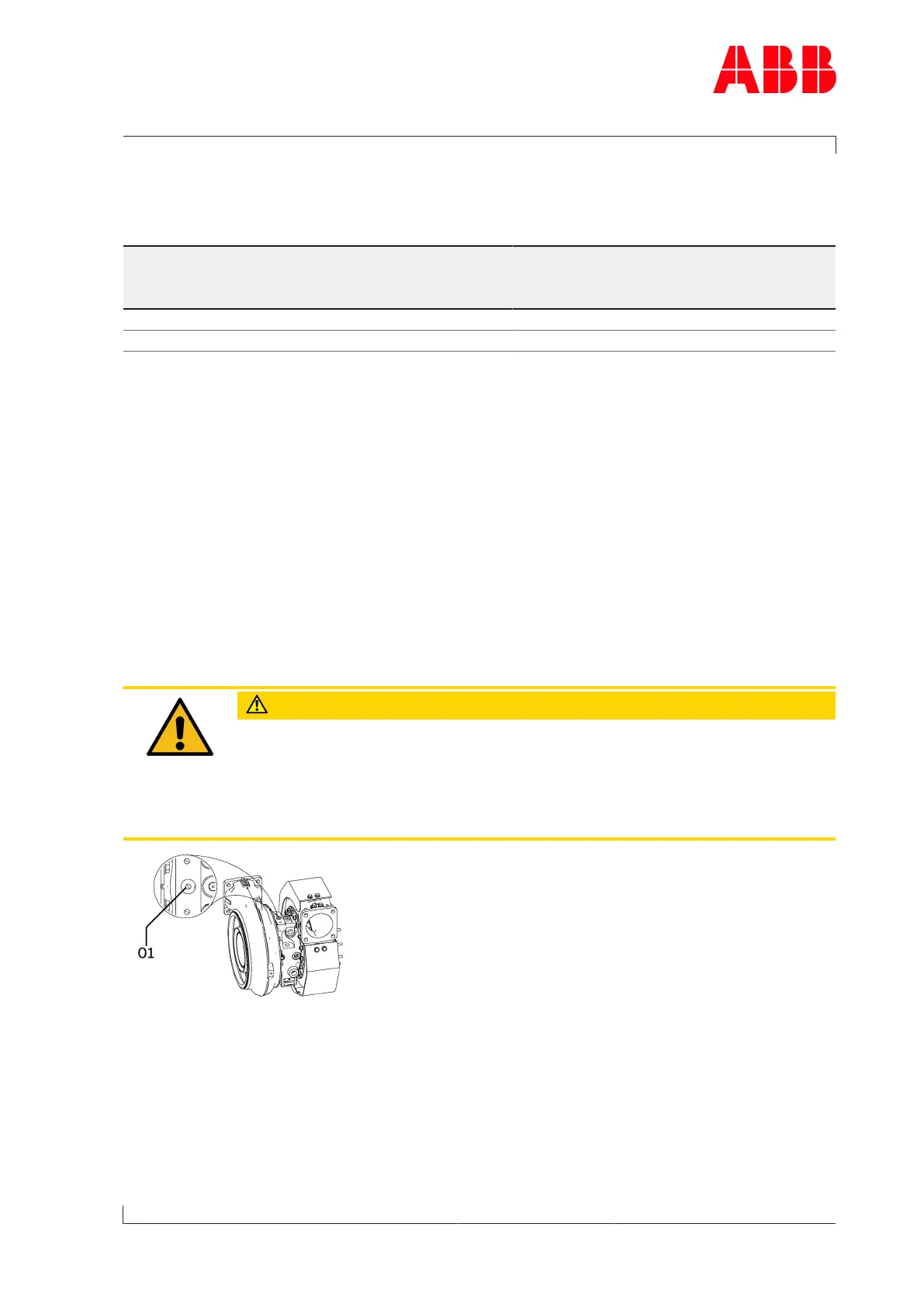

Fig.9: Connecting the compressor cooling air intake

u Remove the lock from the connection for the compressor wheel cooling (01) and fit the

cooling air line.

Page 13 / 17

Loading...

Loading...