14 ACH550 Installation, Operation and Maintenance Manual

ACH550-UH

R1…R6, wiring UL type 12 enclosure

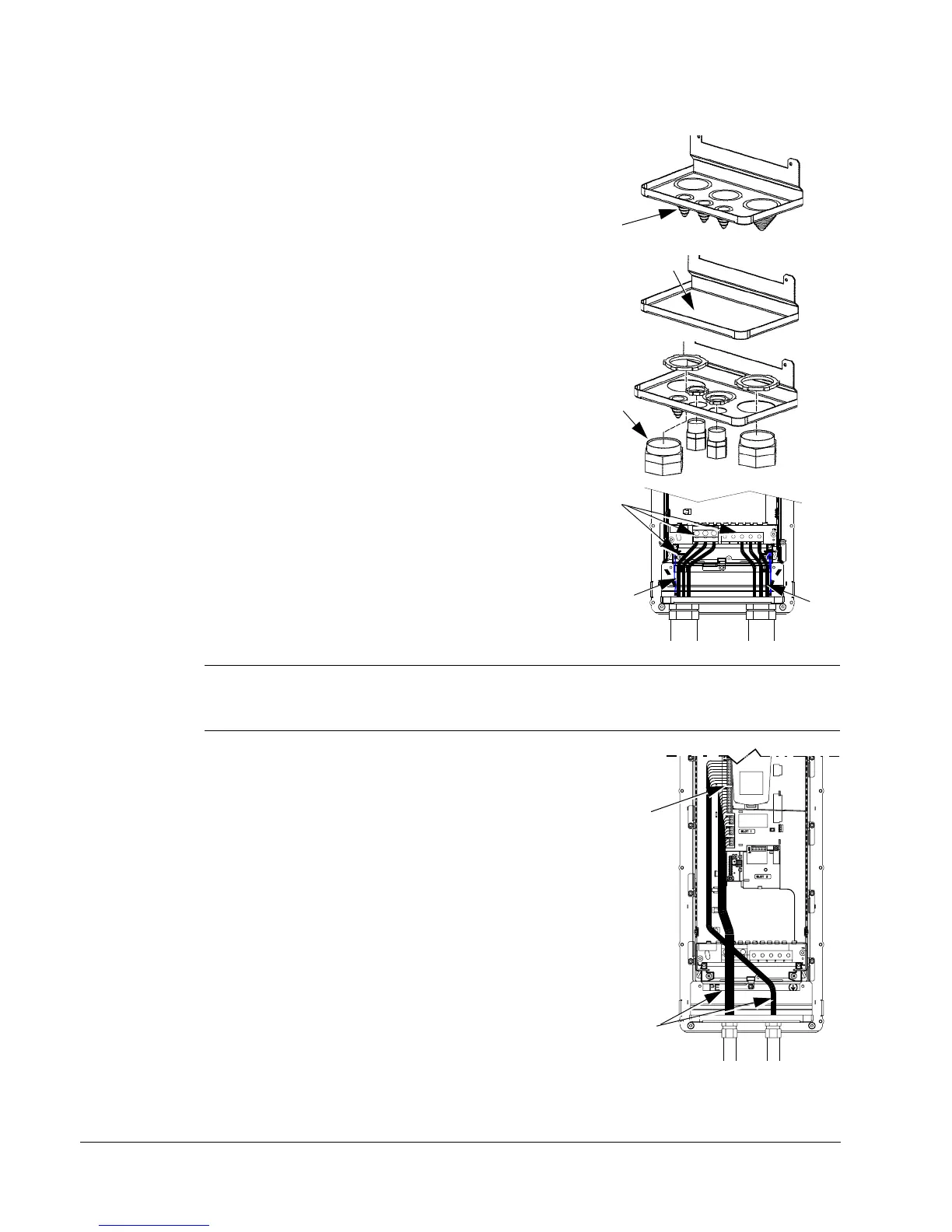

1. Step depends on Frame Size:

• Frame Sizes R1…R4: Remove and discard the

cable seals where conduit will be installed. (The

cable seals are cone-shaped, rubber seals on

the bottom of the drive.)

• Frame Sizes R4 and R5: Use punch to create

holes for conduit connections as needed.

2. For each conduit run (input power, motor and

control wiring must be separate), install liquid tight

conduit connectors (not supplied).

3. Route the power wiring through conduit.

4. Route the motor wiring through conduit (not the

same conduit as input power wiring run).

5. Strip the wires.

6. Connect the power, motor, and ground wires to

the drive terminals.

Note: For R5 frame size, the minimum power cable size is 25 mm

2

(4 AWG). For R6

frame size, refer to Power terminal considerations – R6 Frame size on page 16.

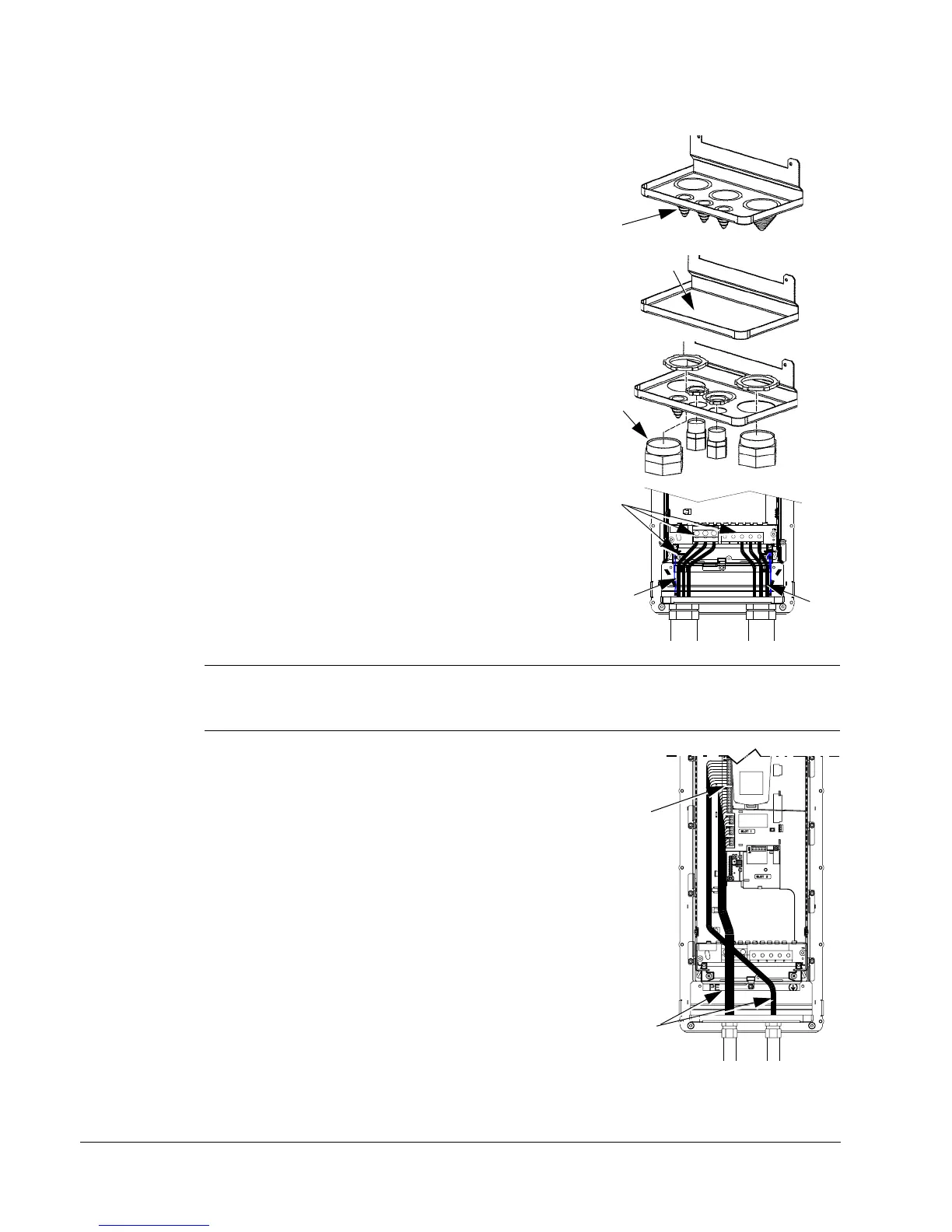

7. Route the control cables through the conduit (not

the same conduit as either input power or motor

wiring runs).

8. Use available secure points and tie strap landings to

permanently secure control wiring at a minimum

distance of 6 mm (1/4") from power wiring.

9. Strip the control cable sheathing and twist the

copper screen into a pig-tail.

10. Connect the ground screen pig-tail for digital and

analog I/O cables at X1-1. (Ground only at drive

end.)

11. Connect the ground screen pig-tail for RS485 cables

at X1-28 or X1-32. (Ground only at drive end.)

12. Strip and connect the individual control wires to the drive

terminals.

13. Install the conduit box cover (1 screw).

Loading...

Loading...