QUICK START

TUBING CONNECTIONS

B - 5

TUBING CONNECTIONS

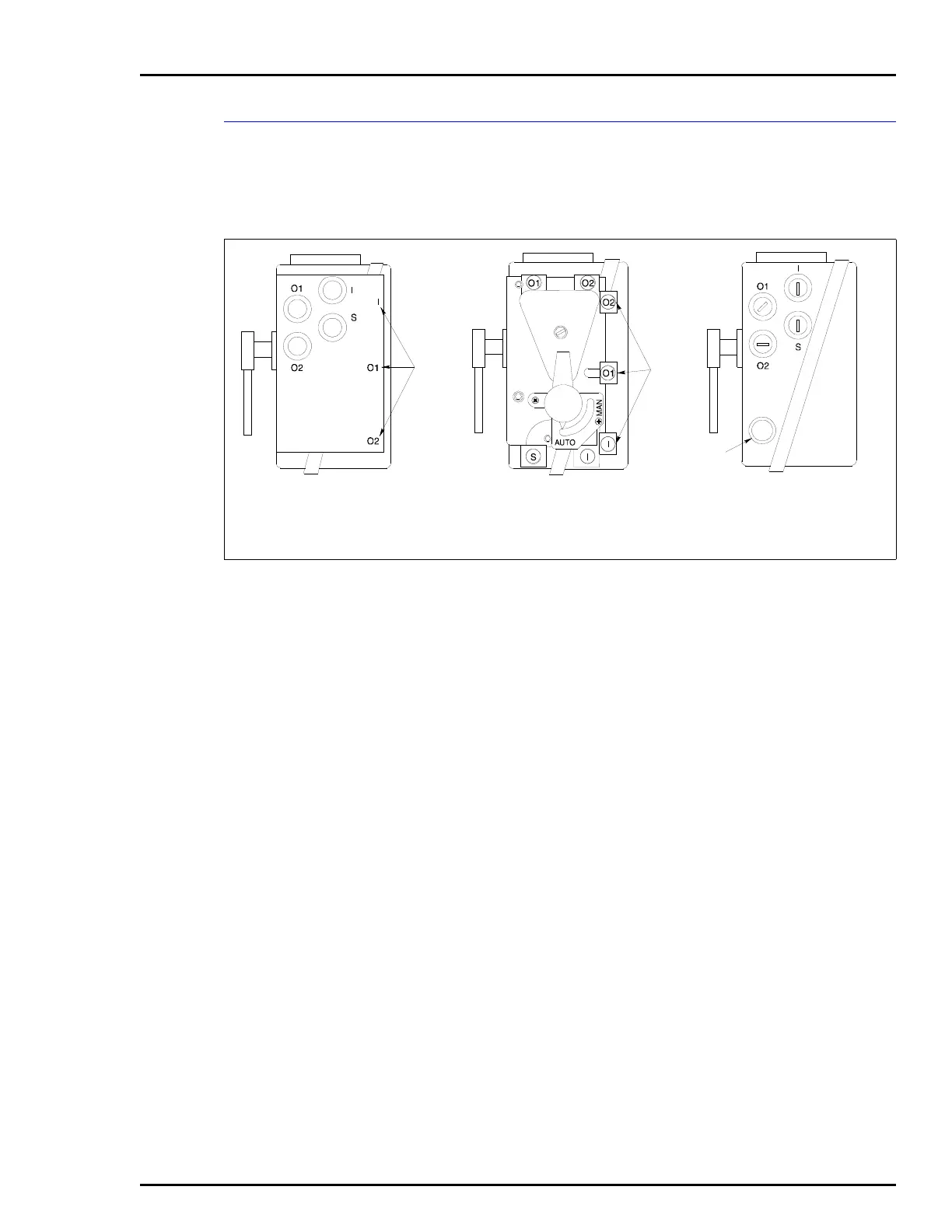

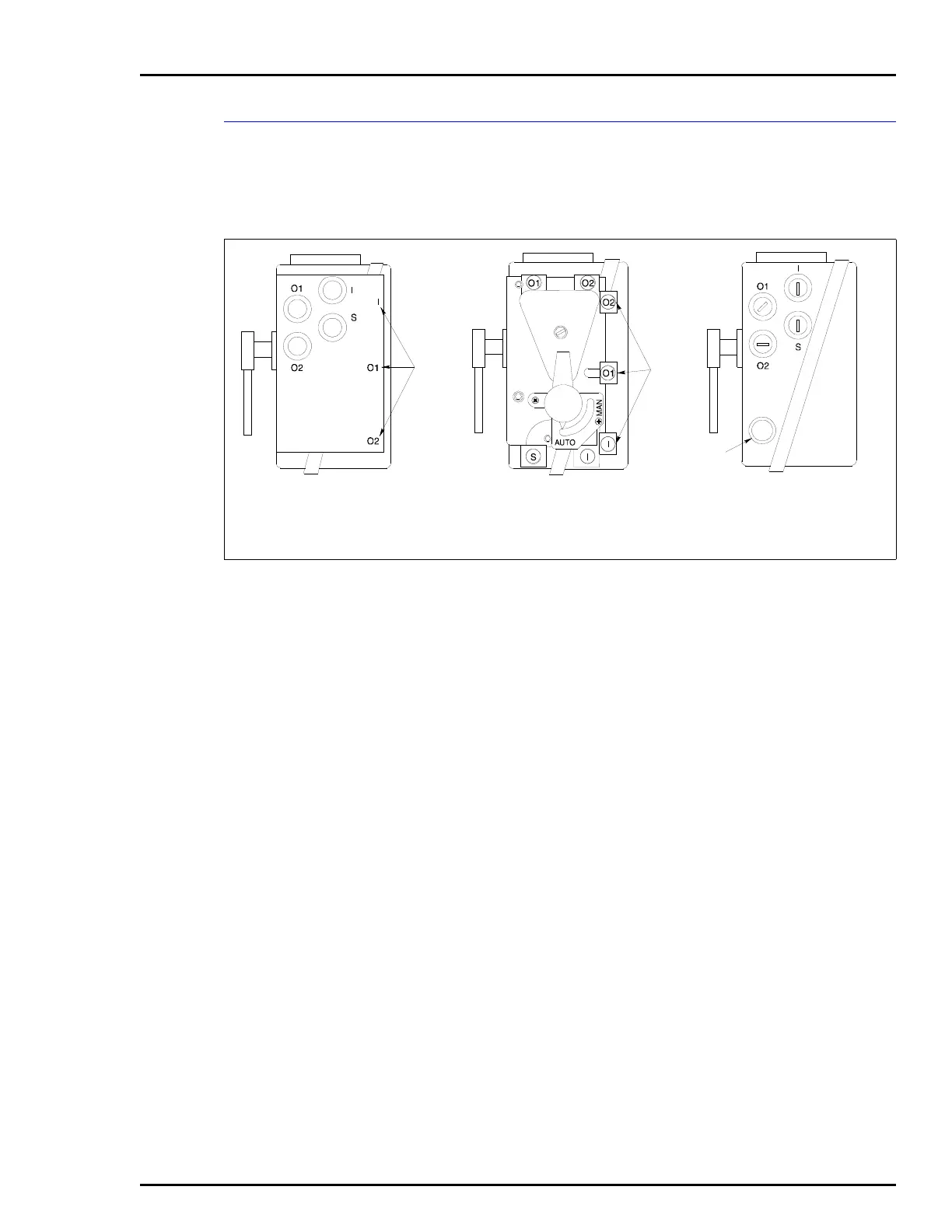

1. Connect the required supply air to connection S (Fig. B-5).

NOTE: Maximum torque for ¼-NPT fittings is 13.6 Nm (10.0 ft-lbs).

2. Based on the positioner type, perform one of the following steps

(Fig. B-5):

• AV11 and AV15: Connect 20.7 to 103.4-kPa (3.0 to 15.0-psig)

instrument signal to connection I.

• AV12 and AV16: Connect 20.7 to 186.2-kPa (3.0 to 27.0-psig)

instrument signal to connection I.

• AV2: Connection I is not used and should be plugged. If it is not

plugged, do so at this time.

NOTE: Use liquid or paste pipe sealant to seal the connection. Max-

imum torque for ¼-NPT fittings is 13.6 Nm (10.0 ft-lbs).

3. Connect the output ports 01 and 02 as required to provide the

desired direction of rotation. Figures B-6, B-7, B-8 and B-9 show a

single acting tubing example, and Figure B-10 shows a double acting

tubing example.

NOTE: The piping arrangements shown in Figures B-6, B-7, B-8,

B-9 and B-10 are general examples and may not reflect the arrange-

ment required for the application.

4. Install -NPT permanent instrument gages to the gage ports if

desired or for calibration requirements.

Figure B-5. Port Locations

T00806A

VIEW WITH GAGE

BLOCK (AV???3???)

VIEW WITH MANIFOLD

(AV???1??? OR

AV???2???)

VIEW WITHOUT

MANIFOLD

(AV???0???)

GAGE

PORTS

GAGE

PORTS

CONDUIT

CONNECTION

Loading...

Loading...