INTRODUCTION

SPECIFICATIONS

1 - 12

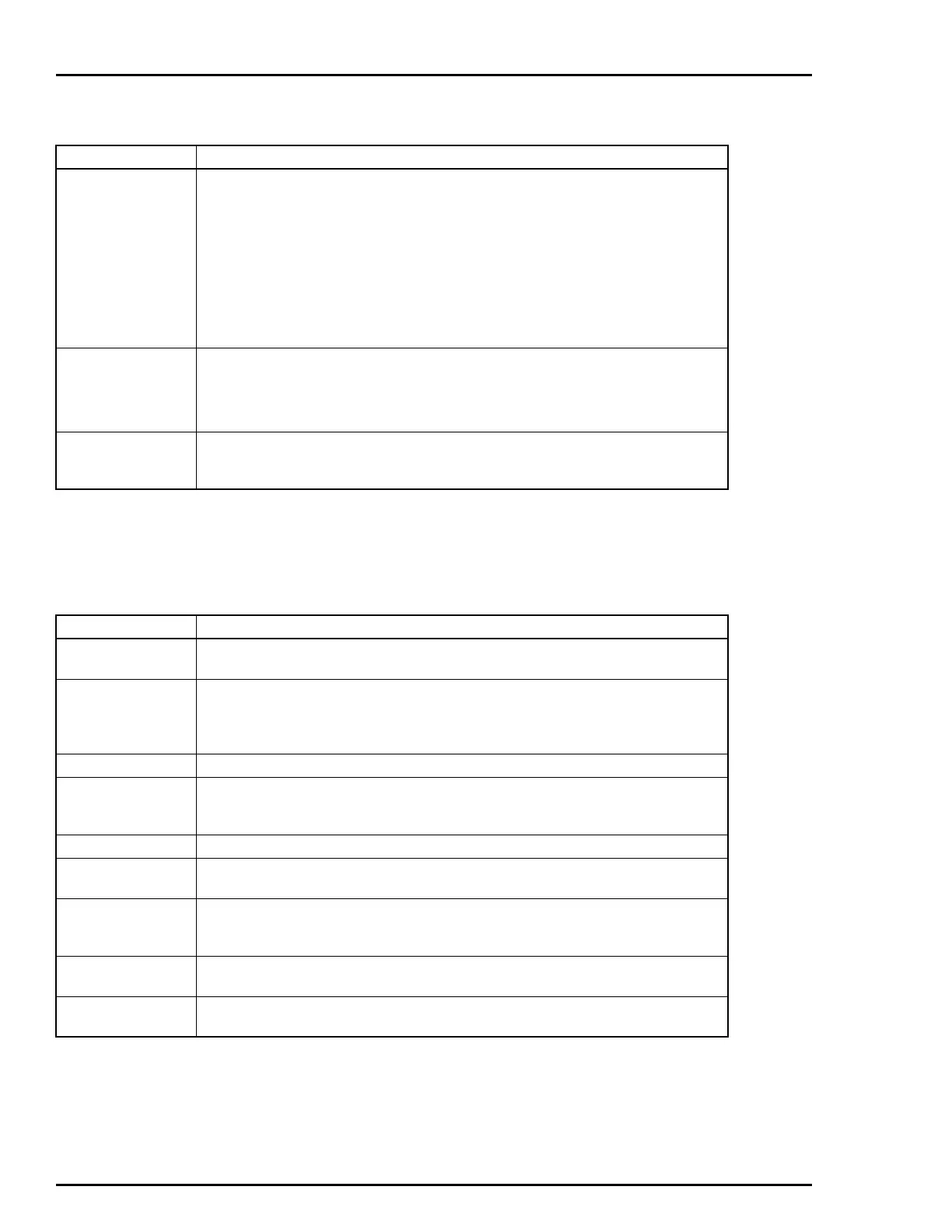

Table 1-6. Agency Approvals

1

Nomenclature Approval/Certification

2

AV1and AV23 Factory Mutual Research (FM):

Approved as nonincendive for:

Class I, Division 2, Groups A, B, C and D

Class II, Division 2, Groups F and G

Class III, Division 2

Approved as intrinsically safe for:

Class I, Division 1, Groups A, B, C and D

Class II, Division 1, Groups E, F and G

Class III, Division 1

Canadian Standards Association (CSA):

Certified as:

Class 1, Division 2, Groups A, B, C and D

Class II, Division 2, Groups E, F and G

Class III, Division 2

Certified as intrinsically safe for:

Class I, Division 1, Groups A, B, C and D

Class II, Division 1, Groups E, F and G

Class III, Division 1

AV27__0__ Factory Mutual Research (FM):

Approved as explosionproof for:

Classes I, II; Division 1, Groups B, C, D,

E, F and G

Canadian Standards Association (CSA):

Certified as explosionproof for:

Classes I, II; Division 1, Groups B, C, D,

E, F and G

All This product complies with all applicable European Community product require-

ments, and specifically with those required to display the CE marking on the product

nameplate.

NOTES:

1. Hazardous locations approvals for use in flammable atmospheres are for ambient conditions of -25°C to 40°C (-13°F to 104°F), 86 to

106 kPa (12.5 to 15.7 psig) with a maximum oxygen concentration of 21%.

2. For installing the positioner in a hazardous location, refer to Product Application Guide, Installing a Type AV Positioner in a Hazard-

ous Location.

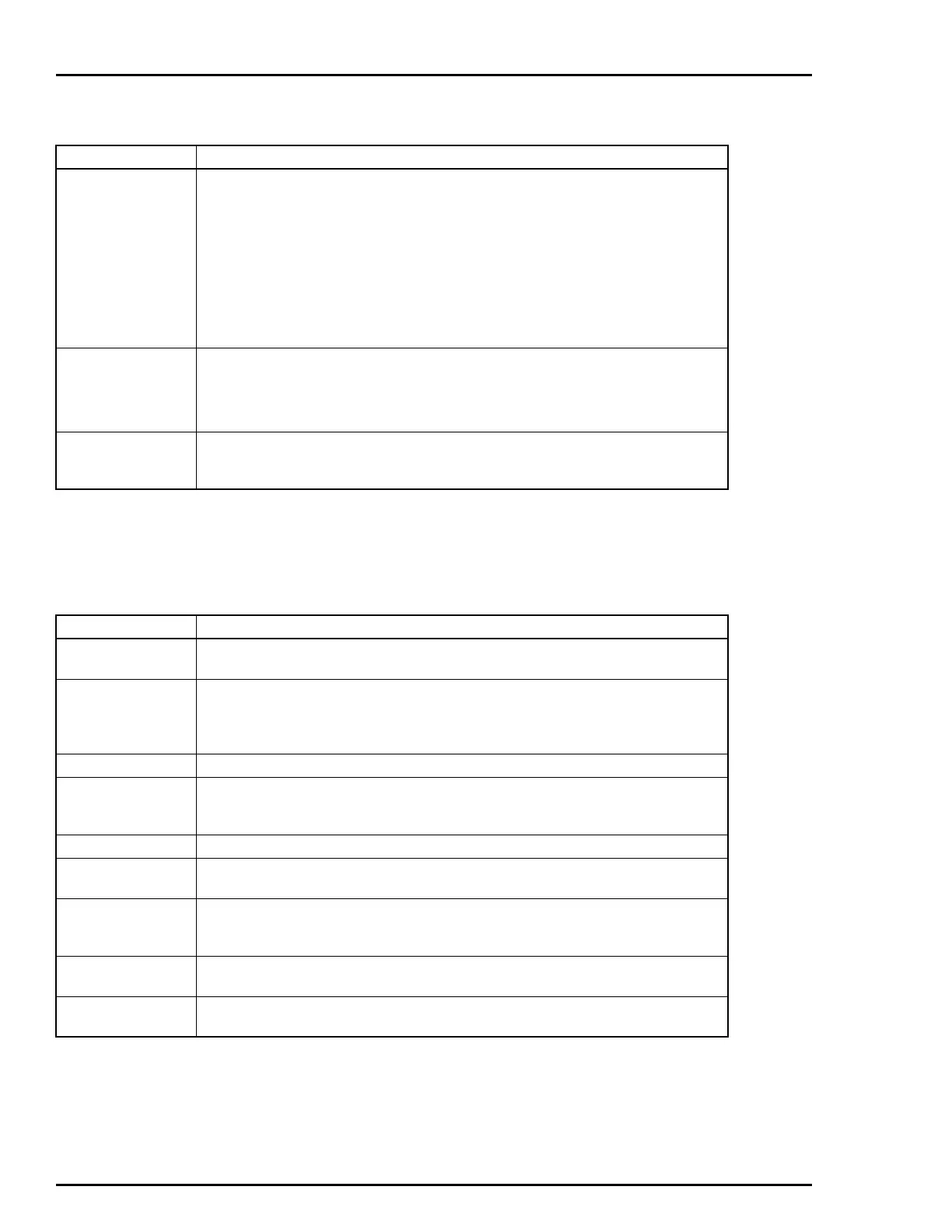

Table 1-7. Accessories

1

Accessory Description

Mounting kits Dependent on valve stem size (Figure 9-1, kit number 5327321__). For ABB retrofit

kits, refer to Table 1-8.

Speed control

orifices

Regulate time constant of positioner and final control device. Orifices are installed

directly into positioner output ports (refer to Table 1-9). Speed adjustment can also be

controlled by using the internal stroke adjustment screws (refer to PILOT VALVE

STROKE ADJUSTMENT in Section 4).

Pressure gages For reading signal, supply and output pressures (refer to Table 1-10).

Blank cam Used to characterize the positioner if the standard cams (square, linear, square root)

will not produce the desired relationship. Blank cam must be profiled (part number

5400277_1.

Supply air regulator Refer to Table 1-11.

Pneumatic position

transmitter

Refer to Appendix D (Type AV1__0___ positioner only).

Air filters ABB recommends installing an air filter in the supply air line to prevent particles from

entering the positioner that can lead to malfunctions. Refer to Table 1-12 for filter part

numbers.

Manifold Filters For addition or replacement of secondary air filters on manifold-equipped positioners.

Kit number 258487_1.

Bypass valve

assembly

Part number 5326945_1. Refer to Table 9-24 and Figure 9-2.

NOTE:

1. For recommended spare parts and additional spare parts, refer to Section 9.

Loading...

Loading...