23

General

Commutator

Under normal operating conditions the

commutator does not require any special

maintenance.

If the commutator surface is rough, it is

essential to check the operating conditions

such as current loading, and environmental

conditions. See the chapter “Brushes and

commutation”.

The action to be taken in the event of a defect

arising from the commutator must be deter-

mined from case to case. Only general advice

can be given.

Corrosive

environment

Inspect the commutator surface before start-up

to see if the machine has been exposed to cor

-

rosive gases. If this has happened, remove the

coating with fine emery cloth, a rubber polishing

block or fine stone.

Commutator

out of true

If the commutator is badly out of true (brush

chatter) or if strong burn marks are evident,

the commutator may have to be skimmed with

a grinder or be carbide/diamond-turned on a

lathe. Centring of The axis must be centred with

reference to the bearing seats.

Roundness is very important. The total indicator

reading (TIR), on a newly-turned commutator

must not exceed 0.020 mm.

In addition, there is also a requirement that the

difference in radius from one lamination to the

next must not exceed 0.004 mm.

The surface roughness should be R

a

=1.6 µm.

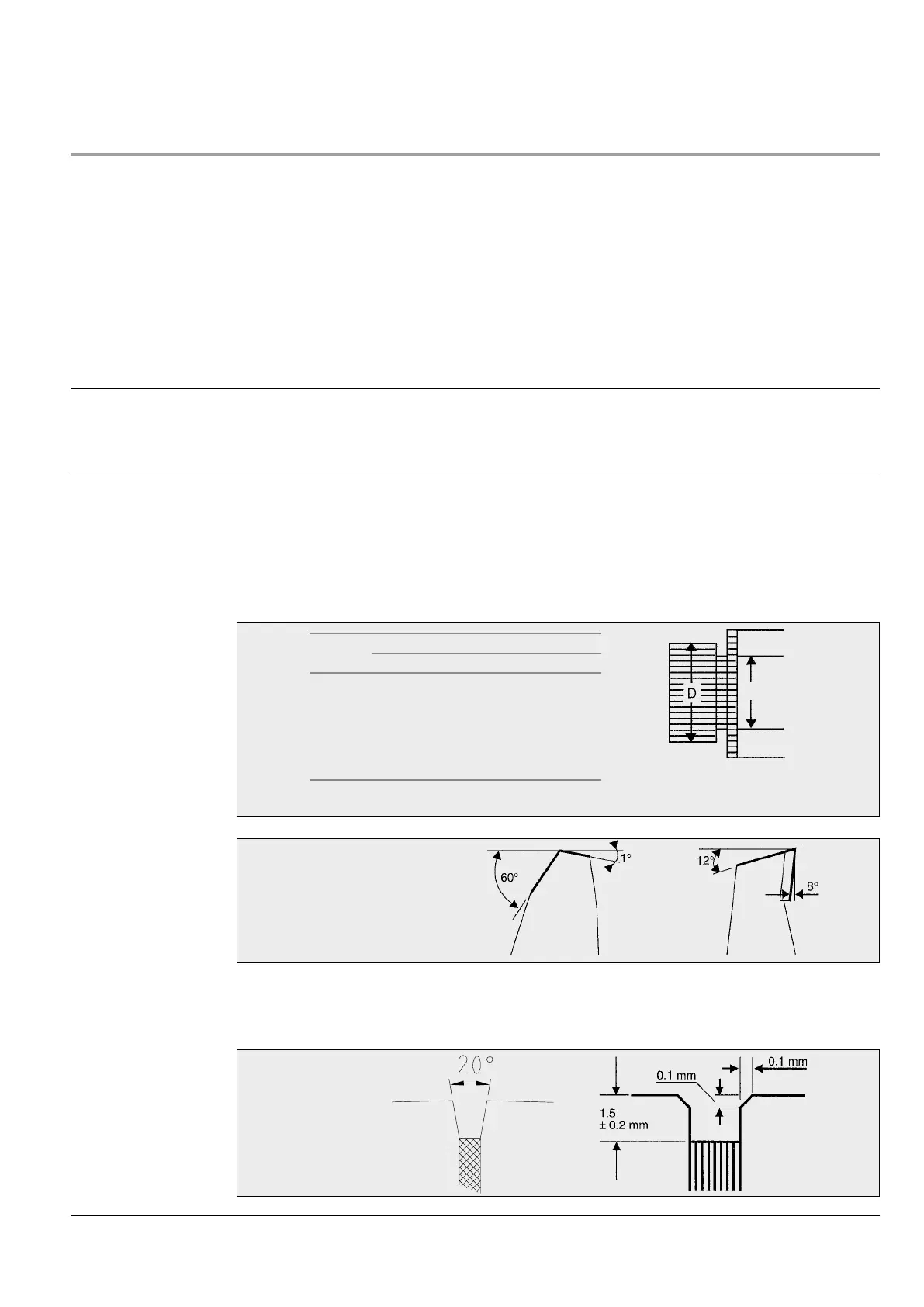

After skimming, the segment insulation may

have to be undercut according to the figure be-

low. The insulation must be cut back far enough

so that chamfering is possible.

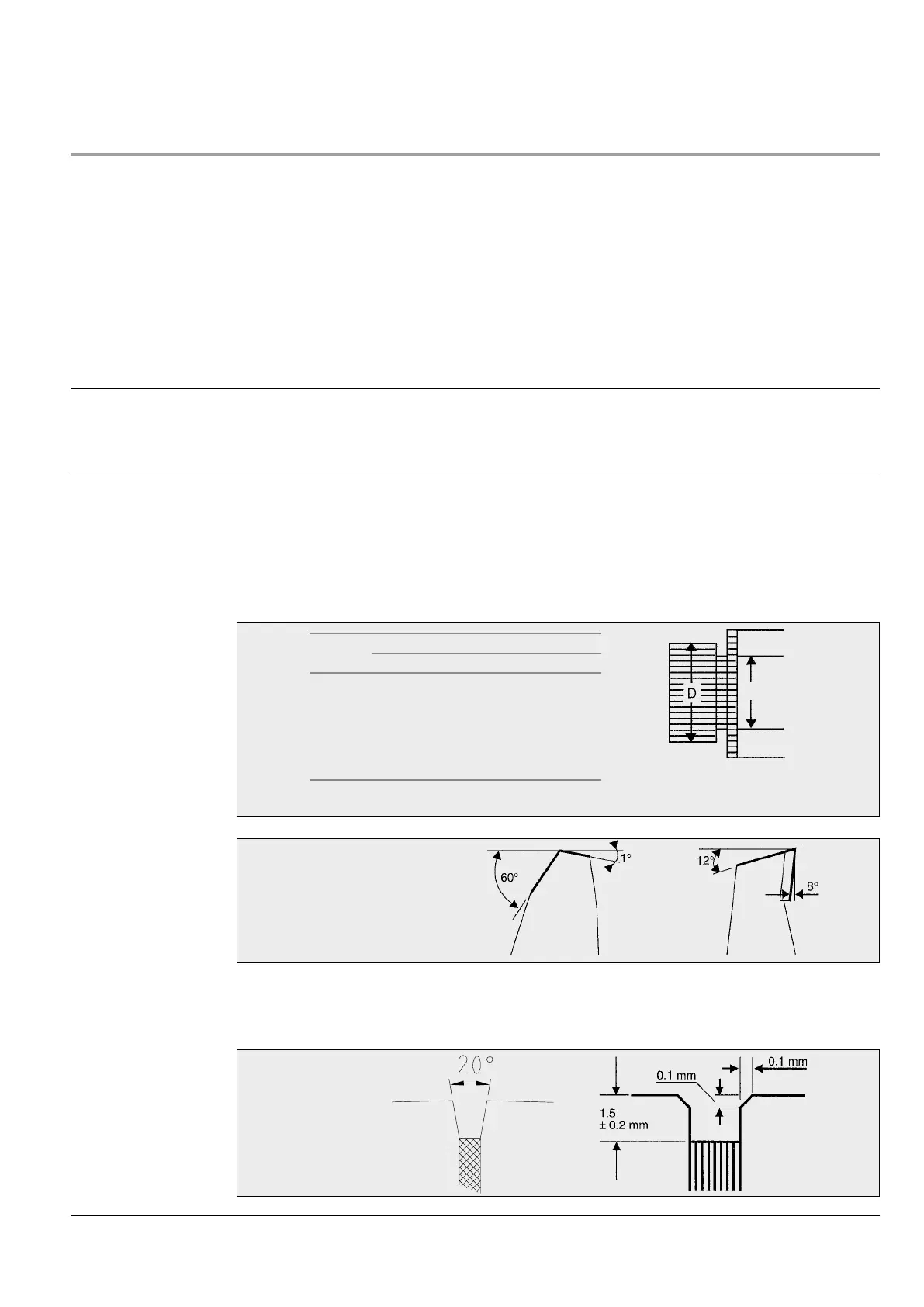

Type Commutator diameter, D (mm)

DMI New Min Depth of wear

180 178 170 4

200 178 170 4

225 235 225 5

250 265 255 5

280 265 255 5

315 330 318 6

400 414 402 6

Fig 14 Turning down dimensions.

Fig 15 Cutting tool for turning.

The distance between the brush holder and the

commutator surface should be 2.5 ±0.5 mm. If

the distance has become larger after turning of

the commutator, the brush holder must be reset.

If the defects are slight, fine emery cloth or

rubber polishing block should be tried first so as

not to remove more of the patina than necessary.

If the patina is of poor quality, ABB recommends

removing it completely.

If the surface is burnt to the extent that craters

have appeared, an abrasive cloth or fine grind-

stone may be used, but great care must be

taken to avoid short-circuits at the laminations.

Grinding should be done at reduced voltage.

D

MIN

Fig 16 The segment insulation must

be undercut to a depth of

1.25 ± 0.45 mm.

Loading...

Loading...