Fläkt Woods 8265 GB 2011.10 2 Specifications are subject to alteration without notice

Installation and maintenance instruction

Fläkt Woods three phase asyncronous motor

Manufacturer: ABB

Use

Operating conditions

Themachinesareintendedforuseinindustrialdrive

applications.

Normalambienttemperaturelimitsare-25°Cto+40°C.

Maximumaltitude1000mabovesealevel.

Safety considerations

Themachineisintendedforinstallationandusedby

qualifiedpersonnel,familiarwithrelevantsafety

requirements.

Safetyequipmentnecessaryforthepreventionof

accidentsattheinstallationandoperatingsitemustbe

providedinaccordancewiththelocalregulations.

Points to observe

1.Donotusethemachinetostepon

2.Thetemperatureoftheoutercasingofthemachine

maybehottothetouchduringnormaloperation.

3.Somespecialmachineapplicationsrequirespecial

instructions(e.g.usingfrequencyconvertersupplies)

4.Liftinglugsmustonlybeusedforliftingthemotor.

Theymustnotbeusedtoliftthemotorwhenitis

attachedtootherequipment.

Handling

Operating conditions

Themachineshouldalwaysbestoredindoors,indry,

vibrationfreeanddustfreeconditions.

Unprotectedmachinedsurfaces(shaft-endsandflanges)

shouldprotectedwithanti-corrosivepaint.

Itisrecommendedthatshaftsberotatedperiodicallyby

handtopreventgreasemigration.

Anticondensationheaters,iffitted,shouldpreferablybe

energised.

Thecharacteristicsofelectrolyticcapacitors,iffittedto

single-phasemotors,willrequire“reforming”following

periodsofstorageexceeding1-2years.

ContactABBSalesOfficefordetails.

Transportation

Machinesfittedwithcylindrical-rollerand/orangular

contactbearingsmustbefittedwithlockingdevices

duringtransport.

Lifting

Onlyliftthemotorusingtheliftinglugs.

Thecenterofgravityofmotorswiththesameframemay

WARNING!

Smallmotorswithsupplycurrent

directlyswitchedbythermallysensitive

switchescanstartautomatically.

varyduetodifferentoutputs,mountingarrangementsand

auxiliaryequipment.

Checkthateyeboltsortheliftingeyesintegratedwiththe

motorframeareundamagedbeforelifting.Damaged

liftingeyesmustnotbeused.

Liftingeyeboltsmustbetightenedbeforelifting.Ifneeded

thepositionoftheeyeboltmustbeadjustedwithsuitable

washers.

Ensurethatproperliftingequipmentisusedandthatthe

sizesofthehooksaresuitablefortheliftinglugs.

Caremustbetakennottodamageauxiliaryequipmentand

cablesattachedtothemotor.directionofrotationisaccor-

dingtothearrowmarkedonthemachine.

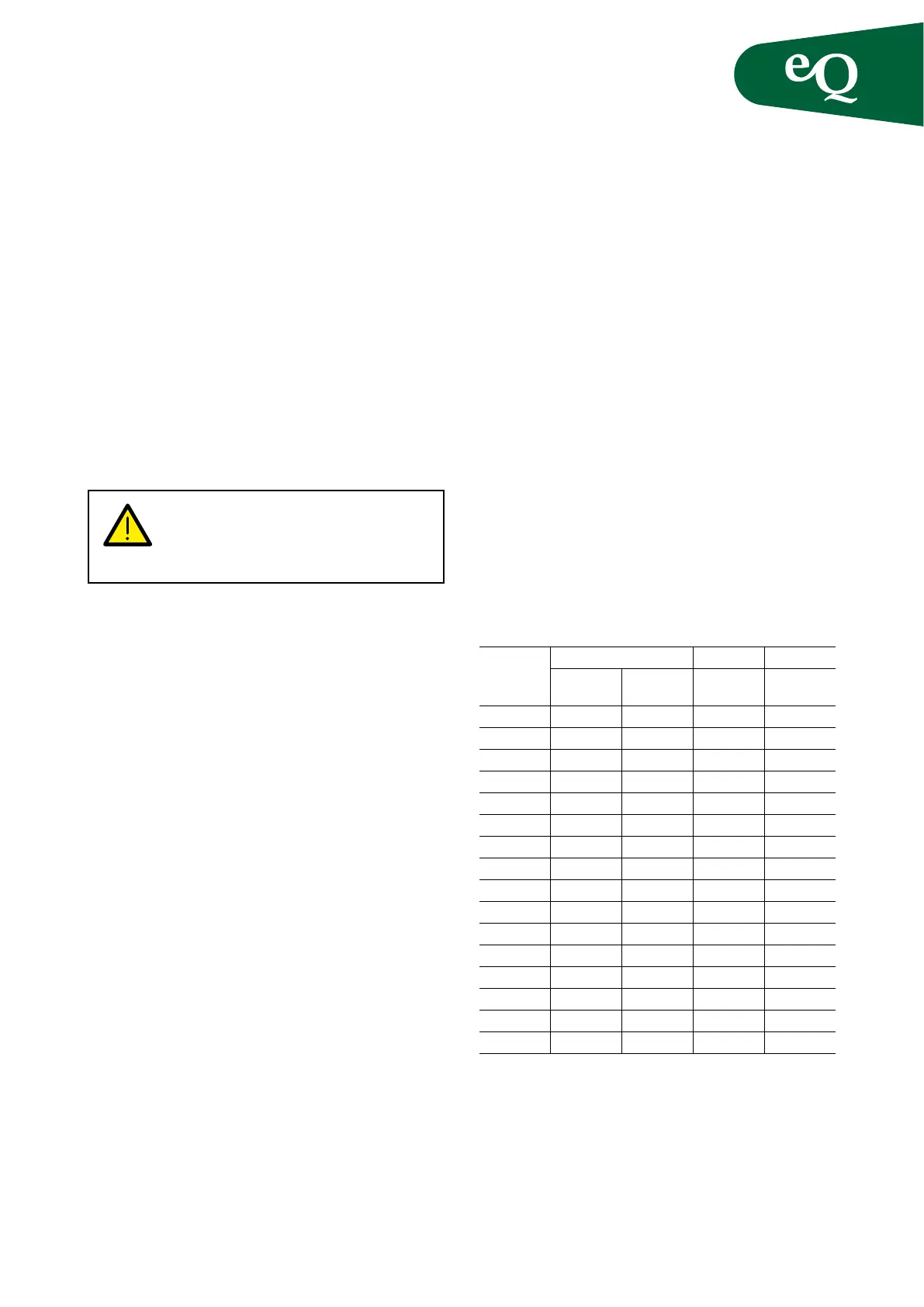

Machine weights

Totalmachineweightcanvarywithinthesameframesize

(centerheight)dependingondifferentoutput,mounting

arrangementsandaddedfeatures.

Thefollowingtableshowsestimatedmaximumweights

formachinesintheirbasicversionsasafunctionofframe

material.

Onmachinesweightingmorethan25kg,theactualweight

isstatedontheratingplate.

Installation

Cooling

Normalambienttemperaturesshouldnotexceed40°C

(marinestandard50°C)ifstandardperformanceistobe

achieve.Checkthatthemotorhassufficientairflow.

Ensurethatnonearbyequipmentorsurfacesradiate

additionalheattothemotor.Formoreinformationabout

higherambienttemperaturesandcooling,see“theMotor

Guide”orcontactABBSalesOffice.

Aluminium Cast iron Steel

Frame

size

Weight

kg

Add.

for brake

Weight

kg

Weight

kg

63 6 - - -

71 8 5 13 -

80 12 8 20 -

90 17 10 30 -

100 25 16 40 -

112 36 20 50 -

132 63 30 90 -

160 110 55 175 -

180 160 65 250 -

200 220 - 310 -

225 295 - 400 -

250 370 - 550 -

280 - - 800 600

315 - - 1300 1000

355 - - 2300 2200

400 - - 3500 3000

Loading...

Loading...