Fläkt Woods 8265 GB 2011.10 3 Specifications are subject to alteration without notice

Installation and maintenance instruction

Fläkt Woods three phase asyncronous motor

Manufacturer: ABB

Foundation

Thepurchaserbearsfullresponsibilityforpreparationof

thefoundation.

Metalfoundationsshouldbepaintedtoavoidcorrosion.

Foundationsmustbeeven,andsufficientlyrigidtowith-

standpossibleshortcircuitforces.Theyshallbedimen-

sionedastoavoidtheoccurrenceofvibrationdueto

resonance.

Foundation studs

Boltthefoundationstudstothefeetofthemotorand

placea1-to-2mmshimbetweenthestudandthefeet.

Alignthemotordirectlyusingappropriatemeans.

Groutthestudswithconcrete,check,alignmentanddrill

holesforlocatingpins.

Drain holes

Alwayscheckthatopendrainholesfacedownward.

Machineswithclosableplasticdrainplugsaredelivered

withtheseopen.

Inextremelydustyenvironments,alldrainholesshould

beclosed.

Alignment

Correctalignmentisessentialtoavoidbearingfailures,

vibrationsandpossiblefracturedshaftextensions.

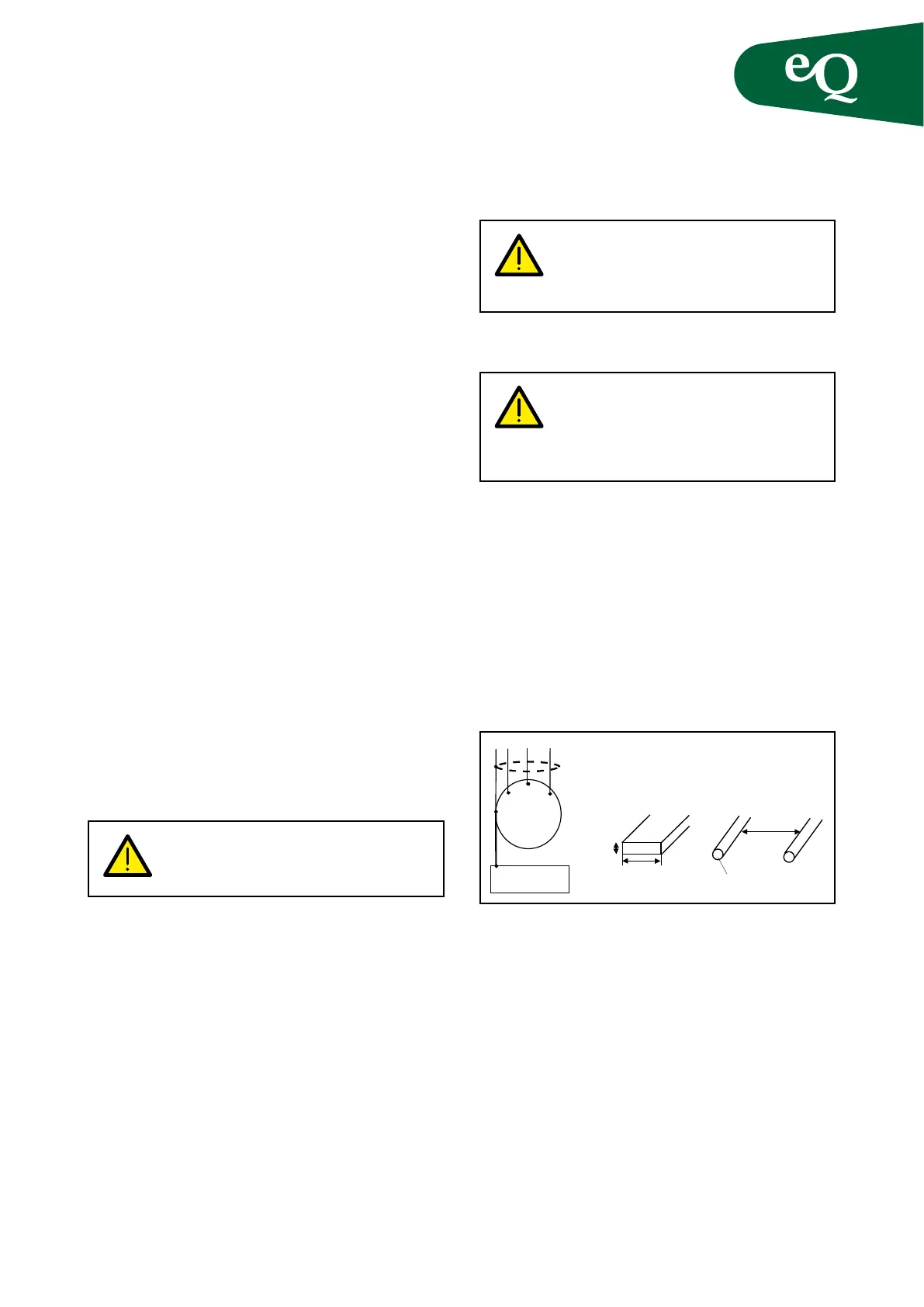

Slide rails and belt drives

• Fastenthemachinetothesliderailsasshowninfigure2.

• Placethesliderailshorizontallyonthesamelevel.

• Checkthatthemachineshaftisparallelwithdriven,

ordriving,shaft.

• Anybeltmustbetensionedaccordingtothesupplier’s

instructions.

Donotexceedthemaximumbeltforces(i.e.radialbearing

loading)statedintherelevantproductcatalogues.

Connection

Thenormalmachinedesigniswiththeterminalboxon

topandwithcableentrypossiblefrombothsides.

Somemachinesareavailable,asaspecialoption,withtop

mountedterminalboxesrotatable4x90°,andsomewith

sidemountedterminalboxes.

Availabilityofthesesolutionsisdescribedintheproduct

catalogues.

Unusedcableentriesmustbeclosed.

Aswellasmainwindingandearthingterminals,the

terminalboxcanalsocontainconnectionsforthermistors,

standstillheatingelements,bimetallic,switches,orPT

100resistanceelements.

WARNING!

Excessivebelttensionwilldamage

bearingsandcancauseshaftbreakage.

Connectiondiagramsforauxiliaryelementsarefound

insidetheterminalboxcover.

In frequency converter applications motorframe

externalearthingmustbeusedforequalisingthepoten-

tialbetweenthemotorframeandthedrivenmachine,

unlessthe two machinesaremounted onthe same

metallicbase.FormotorframesizesaboveIEC280,use

0.75x70mmflatconductororatleasttwo50mm²round

conductors.Thedistanceoftheroundconductorsmust

beatleast150mmfromeachother.

Thisarrangementhasnoelectricalsafetyfunction;the

purposeistoequalisethepotentials.Whenthemotor

andthegearboxaremountedonacommonsteelfunda-

ment,nopotentialequalisationisrequired.

TocomplywithEMC-requirements,onlycablesand

connectorsapprovedforthispurpose.(Seeinstruction

forfrequencyconverters.)

Assembly and dismantling

General

Dismantlingandassemblyofmachinesmustbecarried

outbyqualifiedpersonnelusingonlysuitabletoolsand

workingmethods.

Bearings

Specialcareshouldbetakenwiththebearings.

Thesemustberemovedusingpullersandfittedby

heatingorusingspecialtoolsforthepurpose.How

toreplacebearingsisdescribedindetailinaseparate

instructionleafletavailablefromABBSalesOffice.

WARNING!

Voltagemaybeconnectedatstandstill

insidetheterminalboxforheating

elementsordirectwindingheating.

WARNING!

Thecapacitorinsingle-phasemotors

canretainachargethatappears

acrossthemotorterminals,evenwhen

themotorhasreachedstandstill.

0.75 mm

70 mm

> 150 mm

min 50 mm

Cables/wire s

Plate/strip

U1

V1

W1

PE

3 ~ M

Driven machinery

Loading...

Loading...