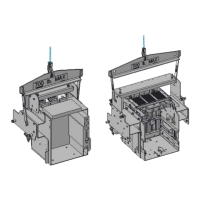

9 Mounting, General

The type SGF two-column rotary disconnector can be mounted in two positions

l Horizontal (standard)

l Vertical (must be expressly specified when ordering and is only possible for rated voltage

< 170 kV)

Note : For vertical mounting of the disconnector, you require the additionally supplied documents.

Should the documents not have been supplied, please send for them. Our address and telefax no. are

given on the left.

The internal parts of the operating mechanisms (e.g. alarm switches and contractors) are not resistant

to outdoor climates. For this reason, they must be protected against moisture during mounting.

9.1 Tools and Materials

Lifting tackle

The lifting tackle for lifting the disconnector poles must have a lifting capacity of at least 500 kg.

Special tools and material

l In addition to the standard tools, the following special tools and materials are required for

mounting.

l Brass-wire brush or treatment of copper surface

l Steel-wire brush for treatment of aluminium surfaces

l Steel-wire brush for treatment of zinc surfaces

l Contact grease Molykote DC55

l Cleaning agent for silver faced surfaces (Rivolta MTX 60 forte)

l Lint-free cloths

Note : Unless special values for torques are specified in these service instructions, the standard values

according to Table 7 apply.

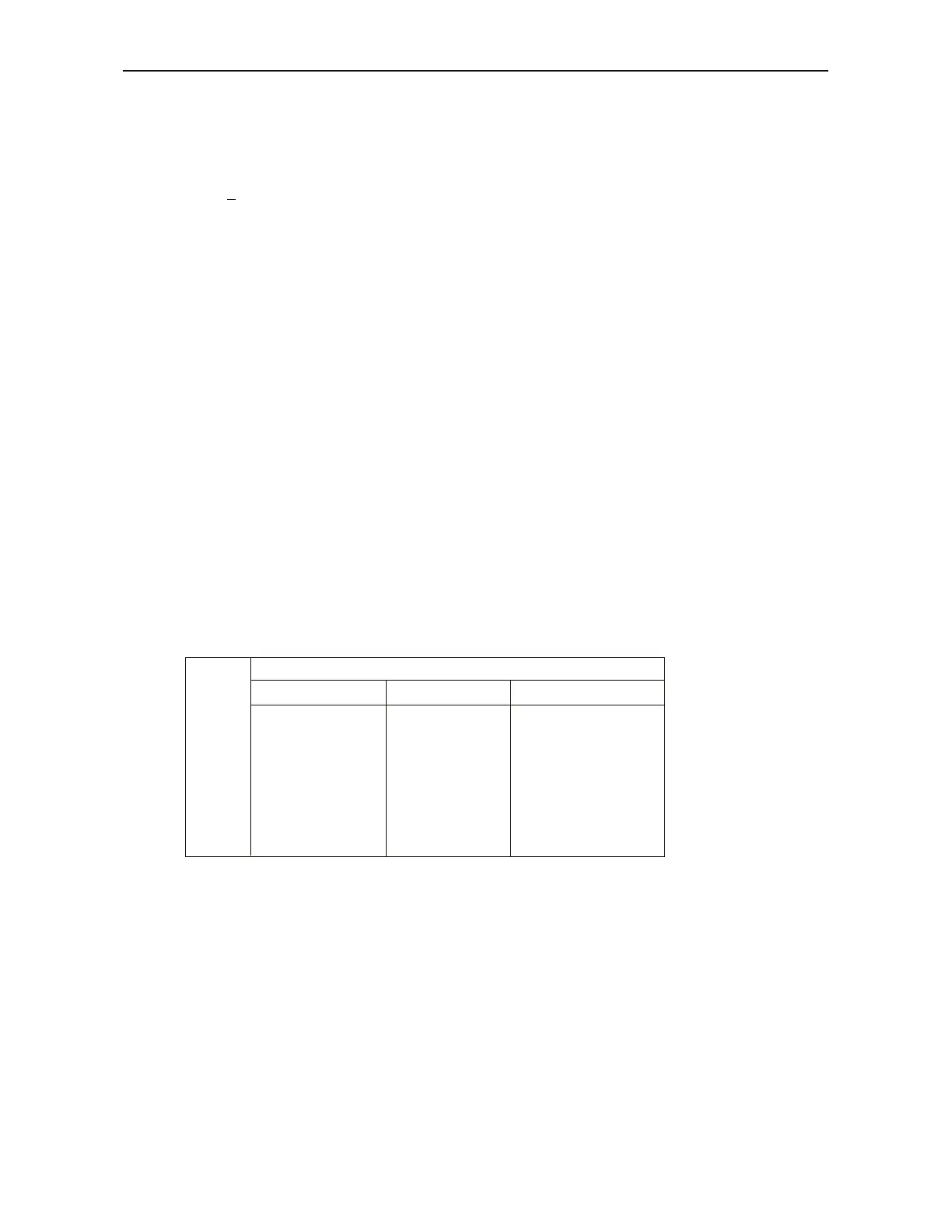

Table 7 : Admissible torque for bolts (standard values)

Thread Torques in Nm

Steel, galvanized Steel, rustproof Thread in aluminium

Strength 8.8 A2-70,A4-70 —

M6 — 7 5.5

M8 — 16 14

M10 42 33 26

M12 72 56 45

M16 174 122 100

Note : In the following mounting steps, a distinction is made between MOUNTING and TIGHTENING.

MOUNTING means finger-tightening. Caution : Lightly grease all bolts before MOUNTING.

Note : In the following illustrations, often only one bolt is shown where two or more bolts are required.

This is done in the interests of clarity.

14/113

1HDB 050016-YN-A

Loading...

Loading...