12 13

(3) Watch the TRI indicator above the LOAD (left hand) capacitor and turn the LOAD capacitor in the

indicated direction to center the green LED indicator light.

(4) Increase the drive power to get the desired nominal output; then repeat steps (2) and (3), always

peaking output with the TUNE adjustment.

NOTE

No light on the TRI indicator means that the tuning is too far off. To correct this,

turn the LOAD and TUNE knobs around the table-suggested positions until the TRI

indicator illuminates.

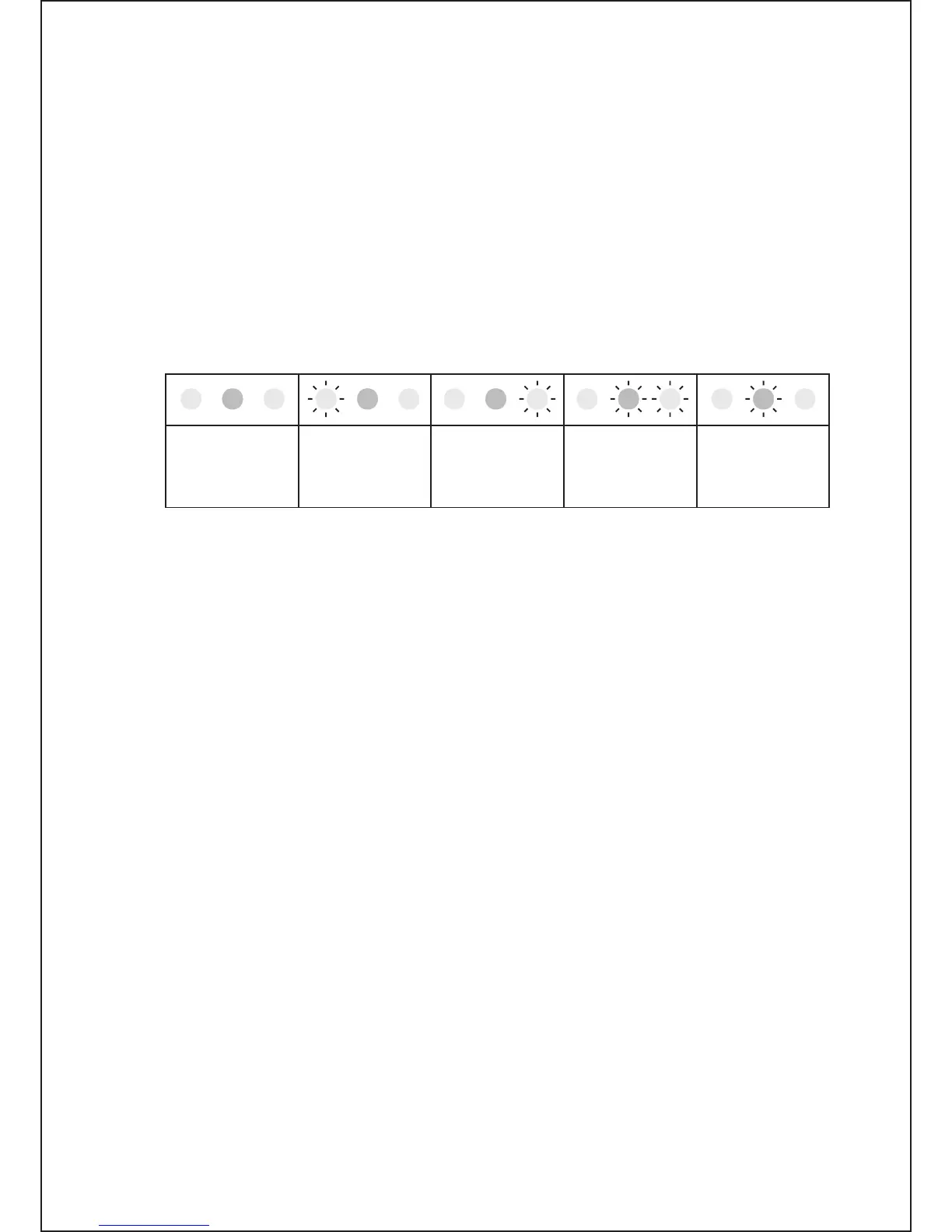

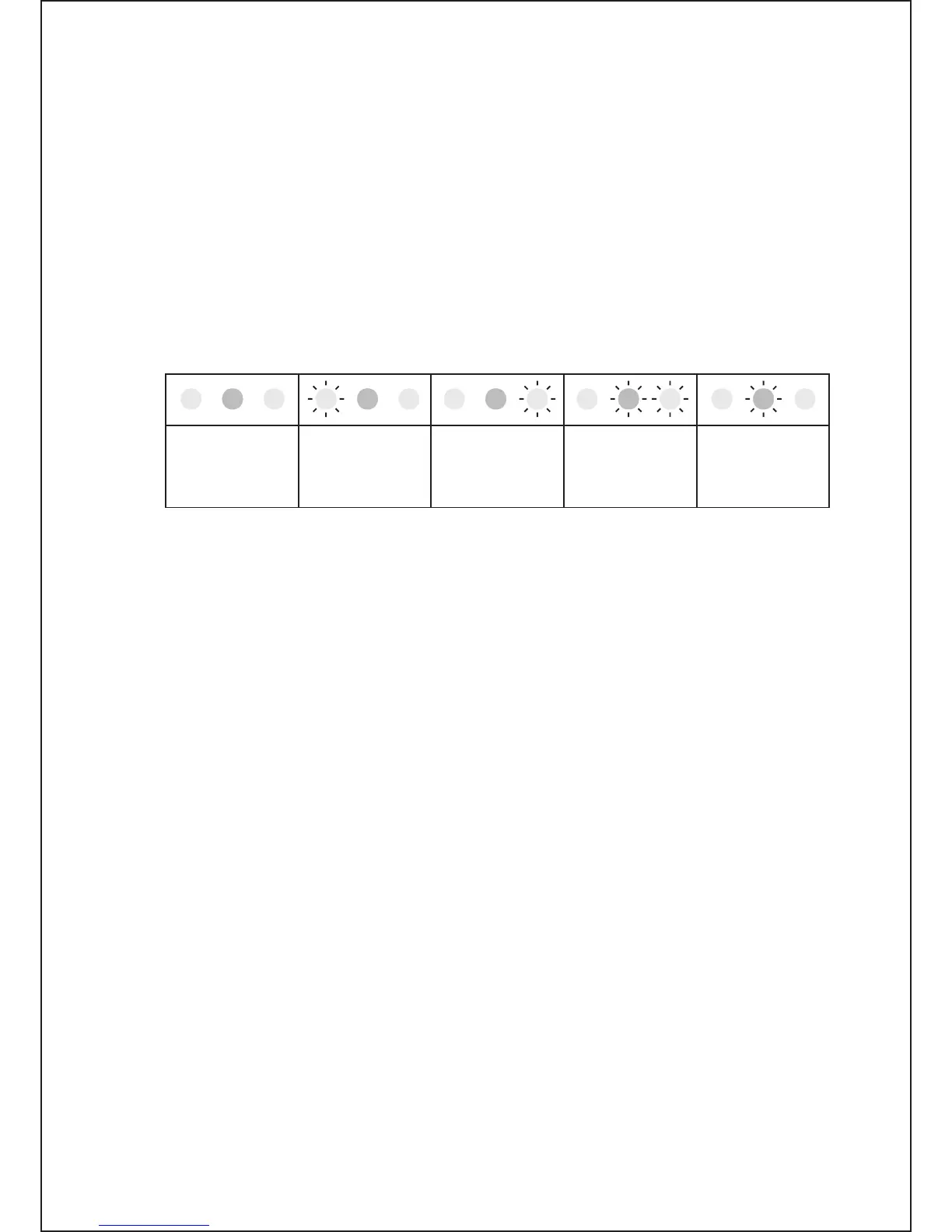

no light:

use TUNE knob

for max. Power

to get any marker

tuning is far left:

turn LOAD knob

to the right to get

the inside markers

tuning is far right:

turn LOAD knob

to the left to get

inside markers

marker inside:

turn LOAD knob

slightly left

to center it

LOAD is tuned:

turn TUNE knob

to peak Forward

Power

Fig. 4-1. Using TRI tuning aid

The TRI indicator will not illuminate until at least 20 W of forward power (output) is achieved. In the event

successful matching cannot be accomplished, check the BAND switch position and antenna selection.

Then check the antenna VSWR at the same drive frequency.

d) Tuning hint. A benefit of TRI is that the knob positions are virtually independent. The plate-load

resistance decreases to the right and increases to the left of the TRI center. A centered tuning indication

corresponds to the proper LOAD capacitor tuning, which presents an optimum load resistance to the

tube.

If the LOAD knob is turned to the left with a centered TRI, there will be more gain, but less linearity.

When available drive power is insufficient or when less output but better efficiency are needed, e.g.,

for RTTY and SSTV, this may be desirable. Tuning to the right of the center would lead to the opposite

result, i.e., less gain and more power attainable. Of course, this requires more drive power, more plate

current, and more plate heat, which shortens tube’s-expected life. Off -center tuning may also be used to

compensate for line (mains) voltage variations in order to maintain tube efficiency. In that case, tune to

the left when line (mains) voltage is high, or tune to the right if it is low. However, where there is more

than a 10% difference from the nominal line (mains) voltage, the voltage selector inside the amplifier

should be changed. See Section 2-2 (Line Voltage Selection).

4-6 The Auto-Protection System

When any abnormal amplifier condition is detected by the auto-protection microprocessor, the risk will

be evaluated automatically and either of two levels of protection will be applied:

a) The first degree of protection consists of an illuminated LED warning. These include the yellow

LED warnings discussed earlier, i.e., “G1” (grid 1), “G2,” (grid 2), and “IP” (plate). Operation may be

continued but the amplifier is likely to proceed to the second degree of protection, the trip.

b) The second degree of protection is a trip to the standby mode. The red “F” (fault) LED illuminates

and the amplifier automatically goes to the standby mode for several seconds. Also, the green OPER

LED goes off. The amplifier will indicate the reason for the protection trip:

Loading...

Loading...