32

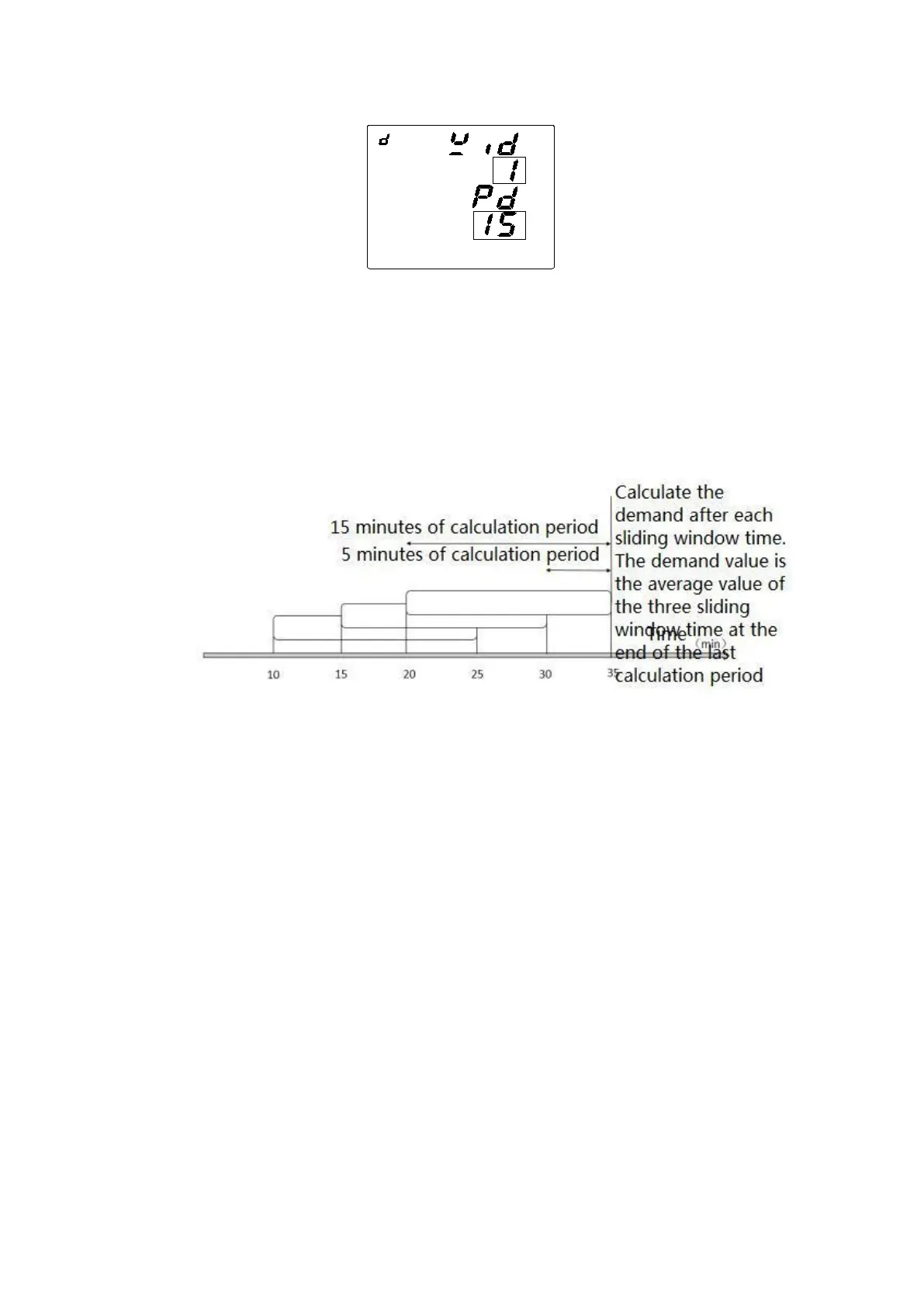

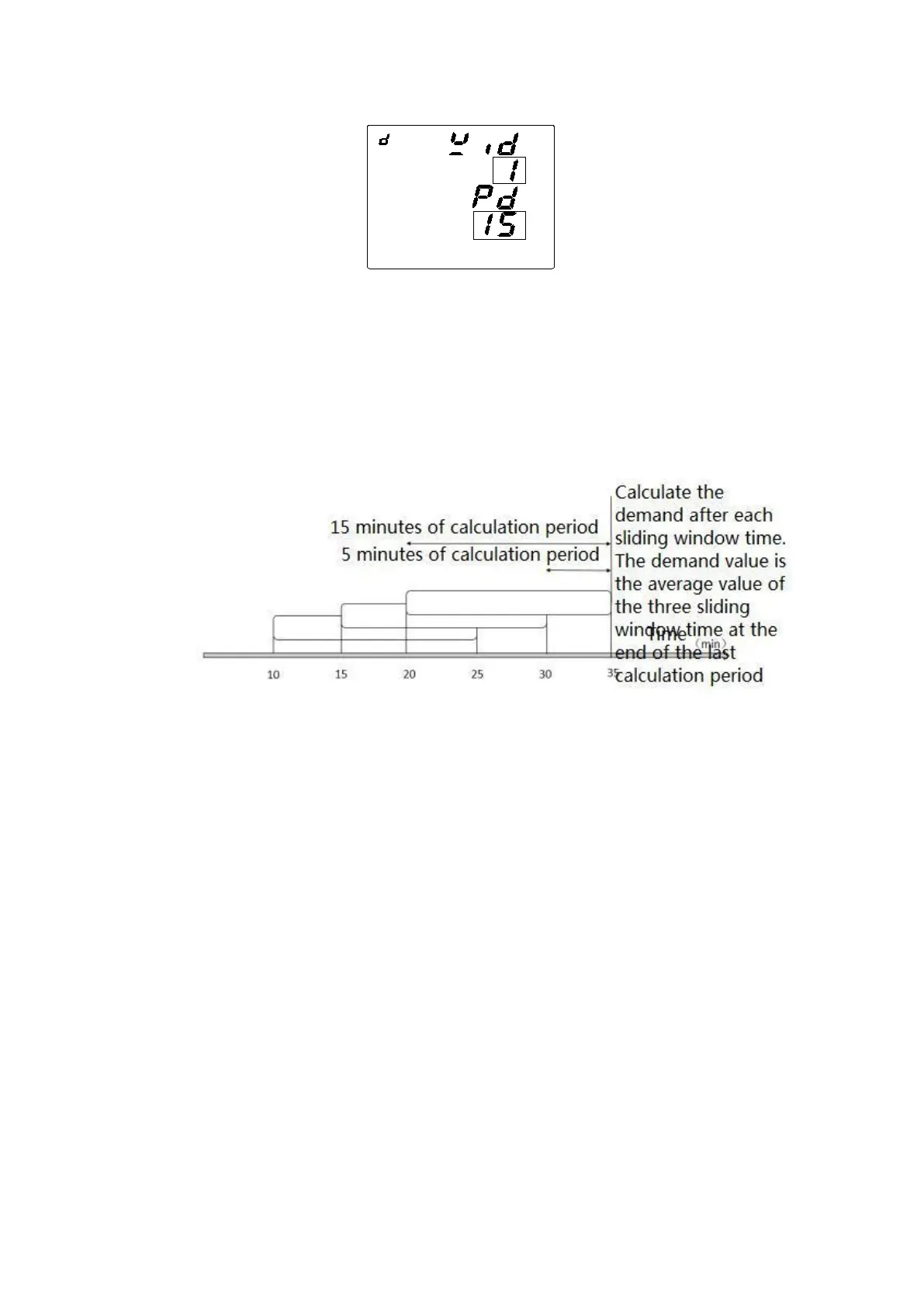

Demand calculation method:

APM series meters use the sliding window method to calculate the demand. In the sliding window calculation cycle, select a

calculation period (Period) and a sliding window (Width). The calculation cycle of sliding window must be divided equally. For

example, three 5-minute sliding windows (Wid = 5, Pd = 15) are set in a 15 minute calculation cycle. Refresh the current demand at

the end of each sliding window. The schematic diagram is as follows:

7.5.9 do settings

1. Press

◀▶

until dio is selected and press the Enter key.

2. Press ◀▶ until do is selected and press the Enter key.

3. Press the

◀▶

keys to select the do number (each main part contains 2 DO outputs and each MD82LOG module adds 2 DO outputs)

and press the Enter key.

4. Press the

◀▶

keys to select Normally Open (N-O) or Normally Closed (N-C) and press the Enter key.

5. Press ◀▶ key to select the do output control mode. ALM1 (alarm group 1) and ALM2 (alarm group 2) are the alarm controls, and

COM is the communication control. Press the Enter key.

6. 1) If you select the alarm (ALM1 or ALM2) control, press ◀▶ key to select the alarm category, press the Enter key.Select the alarm

subclass, press the Enter ke.Select whether to enable,press the Enter key. A DO can select multiple alarms for combined alarms.

2) If communication (COM) control is selected, modify the delay (DLY)time ranged 0-9999, unit 1 second. When it is set to 0, it is a

level control. When it is not 0, it is a pulse mode control,and it is disconnected after the delay time is set.

7. Press the SET button to return.

Note:

① When the output control mode of do1 is selected as ALM (ALM1 or ALM2), and is not associated (DISABLE)with

any alarm of ALM or associated with all alarms (ENABLE), When any alarm of this group (ALM1 or ALM2)is

Loading...

Loading...