20 - EN

EN

NLC_A cod: 1606.4037360_00

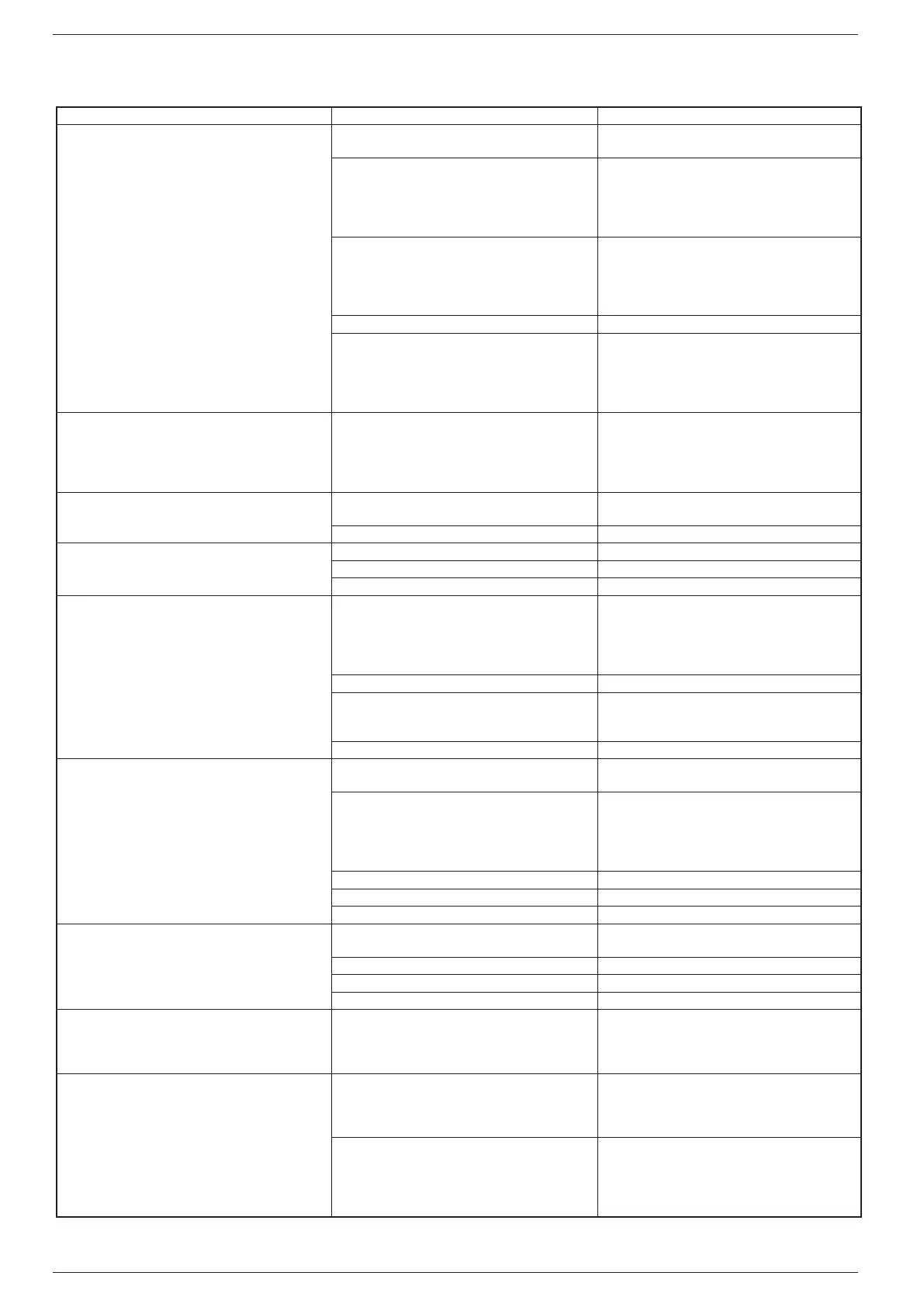

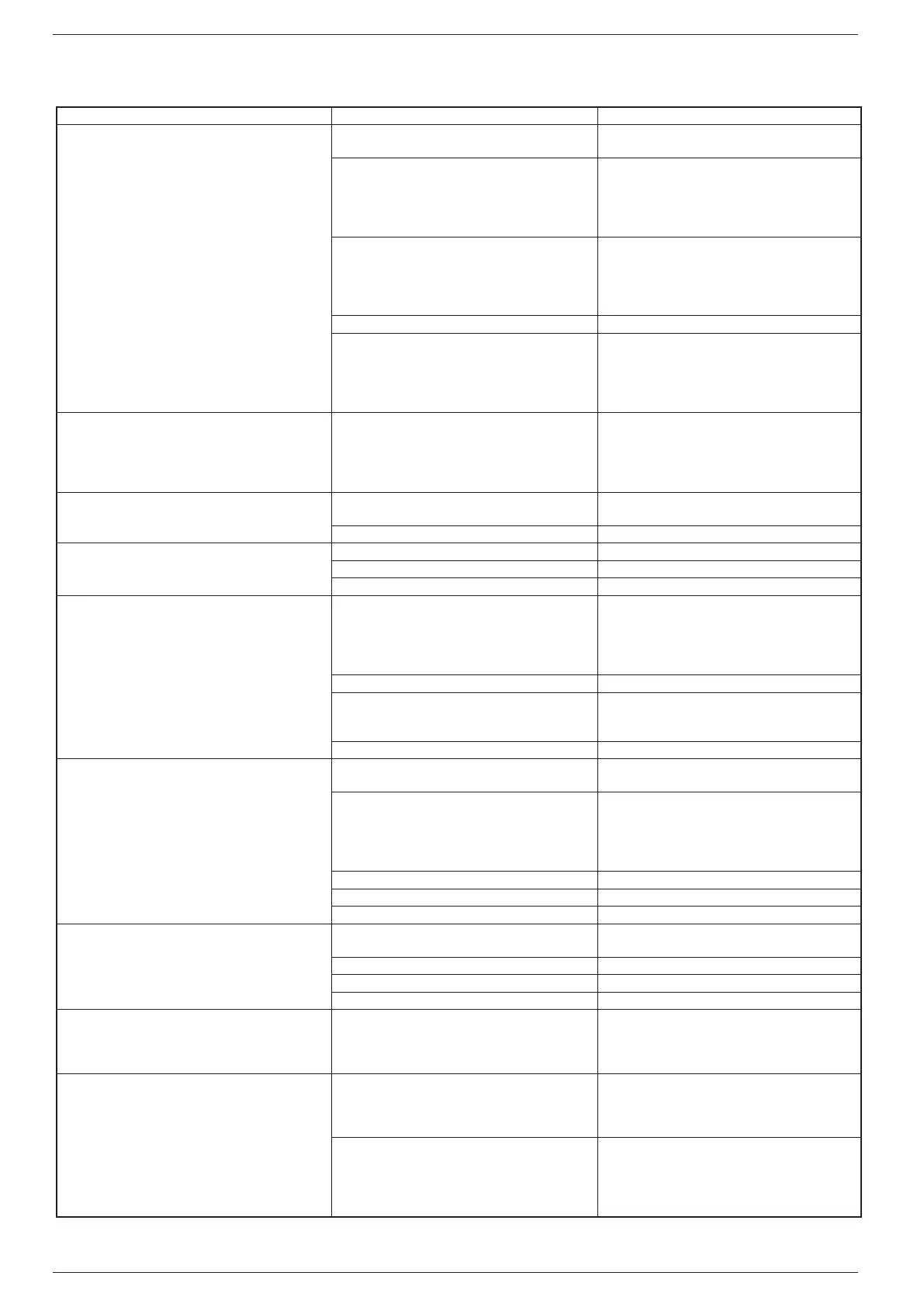

IRREGULARITY CAUSE SOLUTION

The unit does not

start

• No electrical voltage

• Check

for voltage

• Check the safety systems upstream of the appliance

• Master switch on OFF

• Remote switch on OFF (if present)

• Control panel on OFF

• Main switch on OFF

• Compressor thermomagnetic switch on OFF

• Set

to ON

• The flow switch is not connected on the termi-

nal board therefore the circuit is open

• Install and wire the flow switch

• NB. DO NOT bridge the contacts on the terminal

board (otherwise the unit will not stop in the event

of insufficient water and the exchanger would be to

throw away!)

• Power supply voltage too low • Check power supply line

• Coil of the compressor remote control switch

is broken

• Electronic circuit board faulty

• Peak condenser faulty

• Compressor faulty

• Replace

the component

Poor yield

• No refrigerant

• Dirty coils

• Water filter clogged

• Appliance dimensioning

• Operating outside the operating limits

• Check the load and any leaks

• Clean the coils

• Clean the filter

• Check performance

• Check the operating limits using the graphics

Compressor

noisy

• Liquid return to the compressor

• Inadequate fixing

• Check

• Inverted phase • Invert a phase

Noises

and vibrations

• Contact between metallic bodies • Check

• Weak support • Strengthen

• Loose screws • Tighten the screws

The

compressor stops due to the intervention of the

protections

• Excessive flow pressure

• Low intake pressure

• Low power supply voltage

• Electrical connections tightened badly

• Operation outside operating limits

• Check the operating limits using the graphics

• Pressure switch malfunctioning • Replace the component

• Circuit breaker protection intervention

• Check the power supply voltage and calibra

-

tions

• Check the electrical isolation of the winding

s

• Flow switch intervention • Check water flow rate

Compressor

high discharge pressure

• High external air temperature

• High utility inlet water temperature

• Check the operating limits using the graphics

• Insufficient air flow

• Insufficient water flow

• Control:

1. operation of the fans

2. Cleanliness of the coil

3. Operation of the pump (speed)

4. Cleanliness of the filter

• Anomalous operation adjusting the fans • Check or replace if broken

• Air in the hydraulic system • Vent the circuit

• Too much refrigerant gas charged • Restore the correct charge

Low

discharge pressure

• Low outside air temperature

• Low water inlet temperature

• Check the operating limits using the graphics,

as above

• Moisture in the refrigerant circuit • Empty and restore the gas charge

• Air in the hydraulic system • Bleed the circuit

• Insufficient gas load • Restore the correct load

High

intake pressure

• High external air temperature

• High utility inlet water temperature

• Thermostatic expansion valve too open or

damaged

• Check the operating limits using the graphics

• Adjust or replace if damaged

Low

intake pressure

• Utilities low inlet water temperature

• Low outside air temperature

• Thermostatic expansion valve damaged or

blocked

• Check the operating limits using the graphics

• Adjust or replace if damaged

• Insufficient water flow

• Insufficient air flow

• Control:

1. operation of the fans

2. Cleanliness of the coil

3. Pump operation (speed)

4. Filter cleanliness

18. TROUBLESHOOTING

Loading...

Loading...