28

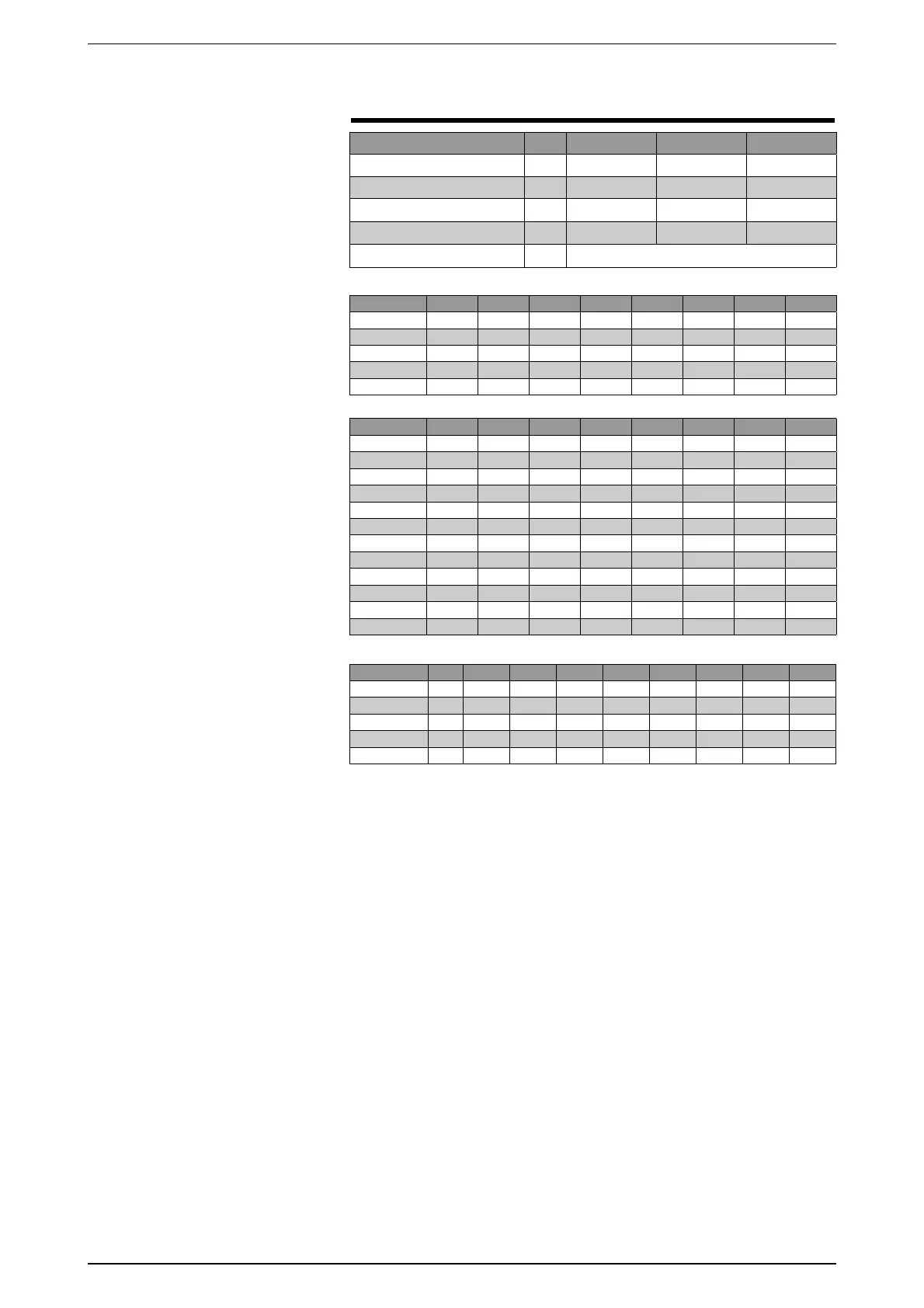

16 CALIBRATION OF CHECK AND SAFETY

PARAMETERS

min. standard max.

Cooling set point °C 4 / -6

(1)

7 / -6

(1)

14

Heating set point °C 35 48 50

Antifreeze intervention °C

-9 3

4

Total differential °C

35

10

Autostart

auto

CHECK PARAMETERS

NOTE

(1) = version Y

161 THERMOMAGNETIC

SWITCHES

FANS

All units are thoroughly tested in the

factory before shipping. Nonetheless,

it is always good practice to check all

control and safety systems after a

reasonable period of operation.

All the control operations must be

carried out by qualified personnel; the

wrong settings on the above devices

can cause serious damage to the unit.

16.3.1 High pressure switch

The high pressure switch stops the

compressor (generating the relative

alarm) when the delivery pressure

exceeds the set value.

The control of its correct working can

be made by closing the air suction

on the exchanger (in cold mode) and,

keeping the high pressure gauge under

control, checking it intervenes upon

reaching the calibrated value.

WARNING

If the switch does not trip at the

calibrated value, stop the compressor

immediately and identify the cause.

Reset is manual and only enabled

once the pressure drops below the

differential value. (For the set and

differential values, see the technical

manual).

16.3.2 Low pressure switch

The low pressure switch stops the

compressor (generating the relative

alarm) when the suction pressure

drops below the set value. The control

of its correct working can be made

(after about 5 minutes of operation) by

slowly closing the tap on the liquid pipe

and, keeping the low pressure gauge

under control, checking it intervenes

upon reaching the calibrated value.

WARNING

If the switch does not trip at the

calibrated value, stop the compressor

immediately and identify the cause.

Reset is manual and only enabled

once the pressure rises above the

differential value. (For the set and

differential values, see the technical

manual).

16.1.3 Anti-freeze control

The anti-freeze control, managed by

electronic regulation and by

the temperature probe at the

evaporator outlet, has the job

of preventing the formation of

ice when the water flow rate

is too low. The control of its

correct working can be made

by gradually increasing the anti-

freeze set until it exceeds the

0800 0900 1000 1250 1400 1500 1650 1800

n° Ventilatori

MTV 1 17 A 17 A 9 A 9 A 13 A 13 A 13 A 17 A

MTV 2 17 A 17 A 9 A 9 A 13 A 13 A 13 A 17 A

MTV 3 / / 9 A 13 A 13 A 13 A 13 A 17 A

MTV 4 / / 9 A 13 A 13 A 13 A 13 A 17 A

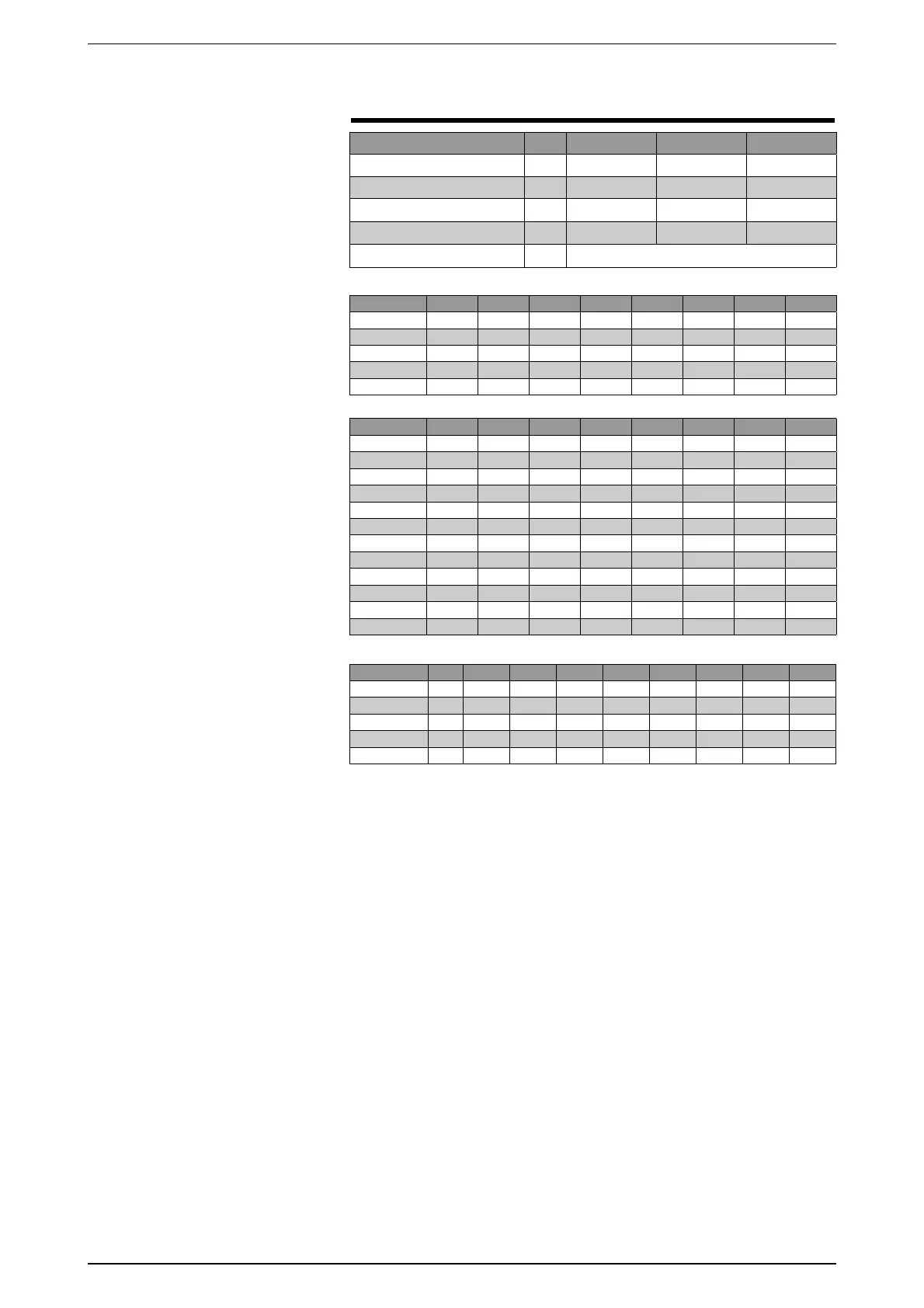

0800 0900 1000 1250 1400 1500 1650 1800

MTC1 53 A 57 A 53 A 53 A 57 A 57 A 53 A 53 A

MTC1A 53 A 57 A 53 A 53 A 57 A 57 A 53 A 53 A

MTC1B 53 A 57 A / / / / 53 A 53 A

MTC2 57 A 57 A 53 A 53 A 57 A 53 A 53 A 57 A

MTC2A 57 A 57 A 53 A 53 A 57 A 53 A 53 A 57 A

MTC2B 57 A 57 A / / / 53 A 53 A 57 A

MTC3 / / 53 A 57 A 57 A 57 A 53 A 53 A

MTC3A / / 53 A 57 A 57 A 57 A 53 A 53 A

MTC3B / / / / / / 53 A 53 A

MTC4 / / 53 A 57 A 57 A 53 A 53 A 57 A

MTC4A / / 53 A 57 A 57 A 53 A 53 A 57 A

MTC4B / / / / / 53 A 53 A 57 A

16.2 THERMOMAGNETIC

SWITCHES

COMPRESSORS

16.3 TRANSDUCERS

PRESSURE SWITCHES

KEY

PA High pressure switch

PB Low pressure switch

TRA High pressure transducer

TRB Low pressure transducer

0800 0900 1000 1250 1400 1500 1650 1800

PA cold 27 27 27 27 27 27 27 27

PA hot H2727272727272727

PB HL22222222

TRA 27 27 27 27 27 27 27 27

TRB 11111111

Loading...

Loading...