microAeth

®

MA Series MA200, MA300, MA350 Quick Start Guide

AethLabs

microAeth

®

MA Series MA200, MA300, MA350 Quick Start Guide

AethLabs

4 5

10) To get the best data from the microAeth MA Series instruments, we highly

recommend that the instrument warm up for approximately 30 minutes so that it can

equilibrate.

11) If you change sampling settings or download data (non-streaming data), you must

stop the instrument measurement before being allowed to make a change. Every time

the measurement starts into the sampling mode, the lter tape cartridge automatically

advances to a clean spot. Stopping and starting the instrument will therefore consume

more tape than just sampling without stopping the measurement intermittently.

Installation & Environmental Considerations

The microAeth instrument is specically designed to be used in a wide range of

measurement scenarios. Each research deployment will require its own specic

considerations for protecting the instrument and ensuring the integrity of your data. The

included sample tubing assembly with threaded insert should be installed into the inlet of

the instrument. Obstruction of either the inlet or outlet port should be prevented as this

will aect the ow of air into the instrument.

In personal monitoring applications, the included lapel clip can assist in positioning the

sampling inlet near to the person’s breathing zone, care must be taken to ensure the inlet,

or microCyclone inlet, are free from obstruction.

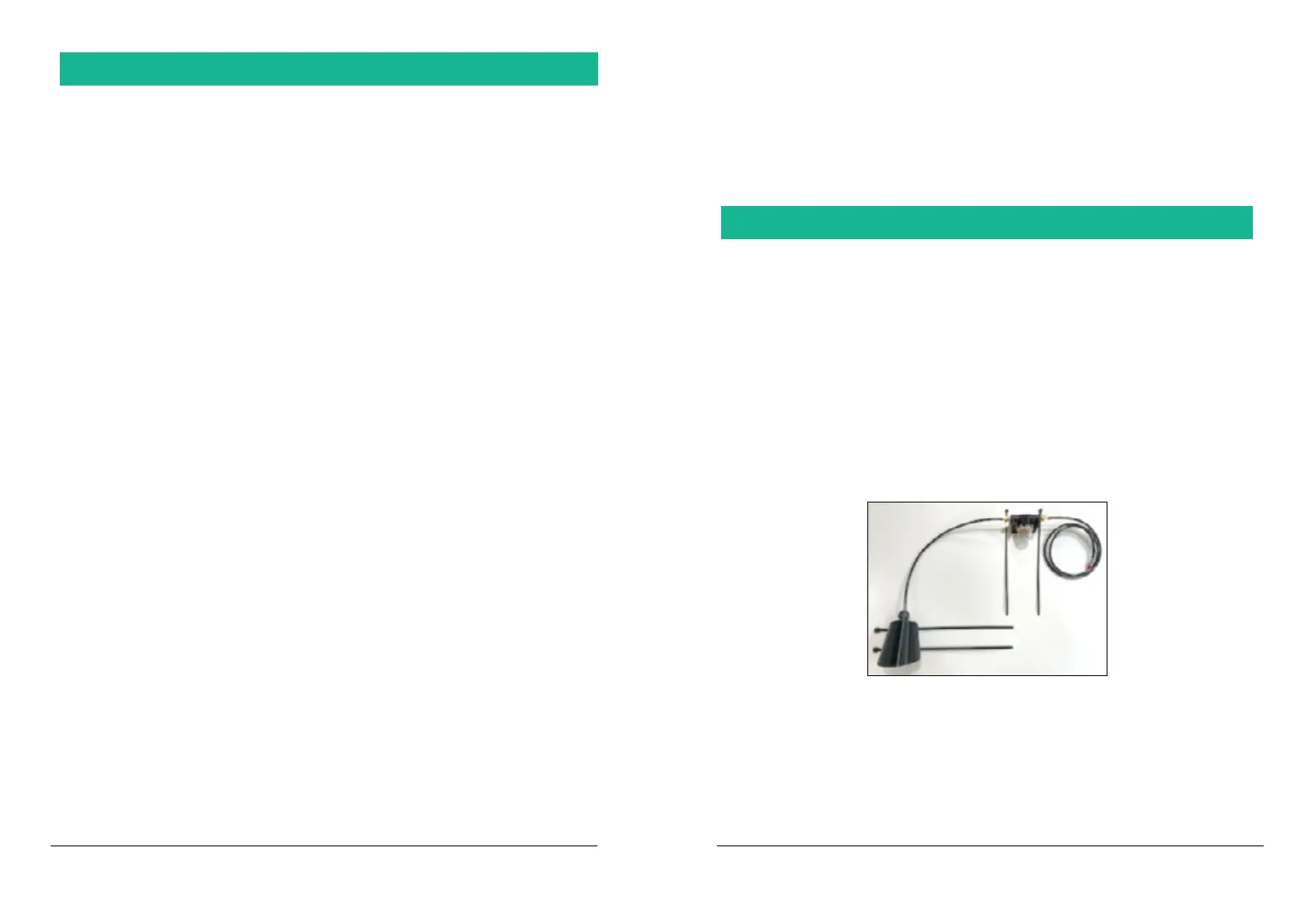

For outdoor deployments, protection of the instrument and the inlet and outlet ports

must be considered. An Inlet Protection Kit (WPK-20-25) should be used to help protect

the instrument and data from moderate water and bug intrusion and in-line condensation

through the sampling train.

Outdoor installation of MA series requires protection from rapid temperature changes and

moisture / precipitation. In addition to potentially having signal-to-noise implications on

your data, rapidly changing environmental conditions can harm your instrument without

proper protection. It is possible that an environmentally controlled enclosure could be

helpful and/or necessary. The instrument should be shielded from solar radiation to

reduce impact of rapid heating from the sun.

The MA350 features more robust weather protection, though it is not completely

weatherproof. While the case itself is rated IP67, necessary penetrations in the enclosure

Important information Before Getting Started

1) The microAeth Manager application for MacOS and Windows can be used to modify

all instrument settings but only some settings can be modied using the on-board user

interface on the front panel of the microAeth instrument.

2) Timebase:

The microAeth MA instruments can acquire data on timebase settings of 1, 5, 10, 30, 60,

or 300 seconds. The 1, 5 and 10 second timebases should only be used under special

circumstances where a decreased signal-to-noise ratio is acceptable. At this setting,

instrumental noise is larger and typically requires the highest ow rate and/or post-

processing. For stationary outdoor applications, we recommend longer timebases such as

the 300 second setting.

3) Flow Rate:

The MA series pump can operate at ow rate settings of 50, 75, 100, 125, 150 or 170 ml/

min. A higher ow rate can contribute to greater measurement sensitivity but will use more

lter tape and more power.

4) The lowest wavelength light source enabled will typically trigger the attenuation

(ATN) tape advance threshold. For example if 5 wavelengths are enabled, the UV channel

should always trigger the tape advance.

5) Measurement Wavelengths: What are you trying to measure? What wavelengths are

important for your measurements? More is not always better. Operating with the IR

channel only will increase tape life by at least 2.3x.

6) Tape advance ATN threshold: If DualSpot® is enabled, a higher ATN threshold can be

used as DualSpot will help correct for aerosol composition dependent loading eects.

7) DualSpot® vs SingleSpot™: A ow rate of 100 ml/min or greater is highly

recommended when using DualSpot® loading compensation. Using DualSpot® will

allow measurements at higher ATN loadings (longer sampling at each lter tape sampling

location) as the data are compensated in the BCc data column.

NOTE: Due to the ow split between Spot 1 and Spot 2 the measurement sensitivity in

DualSpot® mode will be lower than in SingleSpot™ mode for the same total ow rate that

is selected. When the DualSpot calculation and compensation is active (when ATN for

BC1 >= 3) the data will have more noise, this is expected behavior. Simple smoothing can

be applied to reduce the noise, or the smoothed columns in the data le can be used if

helpful.

8) Protect the instrument and the inlet and outlet ports from water and other

contaminates. Aethlabs can provide an inlet protection kit with a water/bug trap with rain

protection at the inlet.

9) Verify ow rates using on-board test ow menu and external ow calibration kit before

calibrating ows. The instruments are initially calibrated at sea level. Only calibrate the ow

system if there is an error in the measured ow when using the test ow menu. if sampling

is being done at a high elevation compared to sea level then a calibration may be required

to compensate for the change in altitude.

Loading...

Loading...