microAeth

®

MA Series MA200, MA300, MA350 Quick Start Guide

AethLabs

microAeth

®

MA Series MA200, MA300, MA350 Quick Start Guide

AethLabs

6 7

for the inlet and outlet are obviously open to the elements. Our inlet and outlet ports are

protected by custom made ttings with dual o-ring seals for backup protection. As long as

the inlet and outlet sample lines are installed in a protected way as described earlier, then

the device is robust and protected from the elements. For continuous monitoring outdoors

we still recommend the instrument be further protected from the sun and precipitation. The

MA350 comes with included mounting hardware for wall mounting. AethLabs also oers a

pole mounting kit.

Temperature:

microAeth instruments are specied to operate between 5 ~ 40 °C. Furthermore, rapid

changes in temperature can impact data. Such eects are inversely propertional to

timebase and ow rate settings. It is possible that an environmentally controlled enclosure

could be helpful and/or necessary depending on the application.

Humidity:

As with many other types of particle measurement instrumentation, changes in relative

humidity can change the size and optical properties of particles. For locations with high

RH variability, an external sample dryer or heater may be used to condition the sample.

AethLabs oers a portable aerosol dryer for this application. Moving between a dry, air

conditioned environment, to a high humidity environment can impact the data while the

device equilibrates. Selecting a higher owrate and longer timebase will help to reduce

these eects.

Contamination:

Preventative maintenance for your deployment and sampling apparatus are important

for protecting your instrument. Keeping the microAeth and its air passageways, internal

components, and optical chambers clean is critical for maintaining the instrument and

producing quality measurements. <bold> We recommend, at a minimum, Standard

Maintenance Service at AethLabs or an authorized service center on at least an annual

basis.

Typically, Black Carbon particles are smaller than one micron in diameter. In some

sampling conditions where the aerosol is primarily composed of light scattering particulate

matter, such as dust or smoke from biomass fuels, there can be a prevalent fraction

of larger-diameter particles. Contamination of the instrument can cause increased

measurement noise, poor sealing of the analytical area and degraded operational lifetime

of some components.

For these applications, and to add contamination protection for your microAeth in high

concentrations, AethLabs oers a microCyclone™ size selective inlet that will limit the size

of the particles entering the microAeth to less than 2.5 microns in diameter when used

at at the specied ow rate. The microCyclone may not be appropriate for use with the

microAeth MA200, MA300, or MA350 in some applications depending on required ow

rates for DualSpot® loading compensation or other application specic ow requirements.

Contact AethLabs for more information.

Recommendations and Best Use Practices

Instrument Settings: We recommend getting started using the 60 seconds timebase and

100mlpm ow rate settings, with 5 wavelengths enabled. After using the instrument in your

application and collecting some data, these settings can be easily changed depending on

your requirements.

SingleSpot™ vs DualSpot®: DualSpot® loading compensation method corrects for the

optical loading eect and provides additional information about aerosol optical properties.

This method simultaneously collects aerosol samples on two analysis spots in parallel and

at dierent face velocities while measuring the rate of change in absorption of transmitted

light due to the particles loading on the lter. The use of this method is an optional user

selectable feature in the microAeth Manager program. DualSpot is usually recommended,

though SingleSpot with a lowered ATN threshold of 50 (with UV enabled) usually has

minimal loading eect in the IR channel

The timebase, ow rate, and WiFi settings will have the greatest impact on battery run

time. NOTE: Battery life will start to gradually diminish after many cycles (~ 1 year of use).

Runtimes can vary based on individual MA series instruments.

Individual Data Point Noise:

Instrumental noise contributes a random perturbation to the ‘ideal’ BC data. Its magnitude

is inversely proportional to the operational parameters of timebase and ow rate. Data

collected on a 1 second timebase should always be smoothed or averaged over longer

periods, unless measuring high concentrations where the instrumental noise is negligible.

Eects of Contamination, Vibration, and Impact: Primarily aected by timebase setting.

Increased ow rate will also reduce the eect.

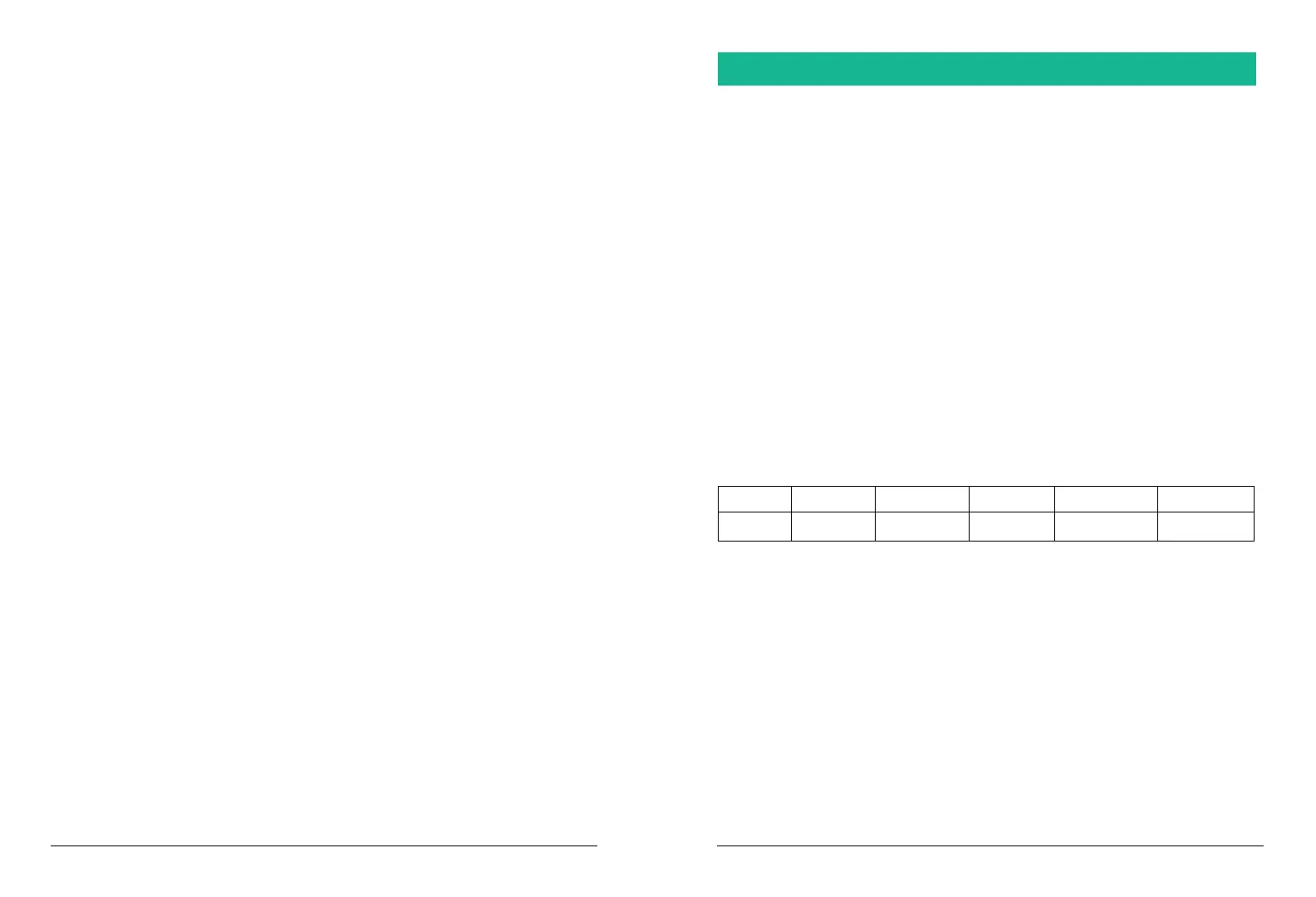

1 second 5 seconds 10 seconds 30 seconds 60 seconds 300 seconds

very large large large moderate low least

Choosing the Tape Advance ATN for your application:

Choosing the right tape advance ATN trigger helps ensure the integrity of your

measurement by reducing possible loading eects. Loading eects are variable, aerosol

dependent, and are not always present. The range of the Tape Advance ATN trigger

is 1 to 100. The lower the Tape Advance ATN trigger setting, the lower the impact of

loading eects on the data at the expense of more tape consumption. Your settings from

SingleSpot™ vs DualSpot®, Flow Rate, and Wavelengths also impact how frequently you

reach your ATN setpoint and tape advance frequency.

Loading...

Loading...