microAeth

®

MA Series MA200, MA300, MA350 Quick Start Guide

AethLabs

microAeth

®

MA Series MA200, MA300, MA350 Quick Start Guide

AethLabs

24 25

Calibration

All microAeth instruments are ow calibrated at approximately standard atmospheric

pressure and room temperature to ensure accurate ow rates at the time of production.

Local operating conditions vary around the world. Temperature and pressure at the time of

calibration are recorded in the ow calibration table header. Before instrument deployment,

we suggest that the ow rates at the inlet of your microAeth instrument are checked.

In general, and especially for sampling at higher elevations, AethLabs suggests calibrating

the ow of your microAeth in the location at which you plan to use it. This will ensure that

the internal mass owmeter is calibrated for the in situ atmospheric pressure.

If re-calibration is needed, it is possible to calibrate to within 1-2% on average using the

AethLabs MA Series Flow Calibration Kit. Only the external mass owmeter provided in

the AethLabs MA Series Flow Calibration Kit is compatible with the MA200, MA300, and

MA350.

Cleaning & Maintenance

If the microAeth is exposed to any liquids or other damaging contaminants, immediately

turn o the instrument, disconnect all cables, and remove any foreign substances

in contact with the instrument. Do not use liquids or other cleaning products on the

instrument. Wait until the microAeth is completely dry before charging or turning on the

instrument. Only AethLabs authorized service personnel should clean the air passageways

and internal components of the microAeth.

AethLabs recommends sending your instrument for annual service, or more frequent

service depending on use and operating conditions. Cleaning intervals will vary based on

the sampling environment and concentrations.

In addition to any necessary repairs, AethLabs oers ow calibration service and standard

maintenance service (including full diagnostics, cleaning, ow calibration, and instrument

testing) at the AethLabs San Francisco oce. AethLabs also has authorized repair

locations in Europe and South America.

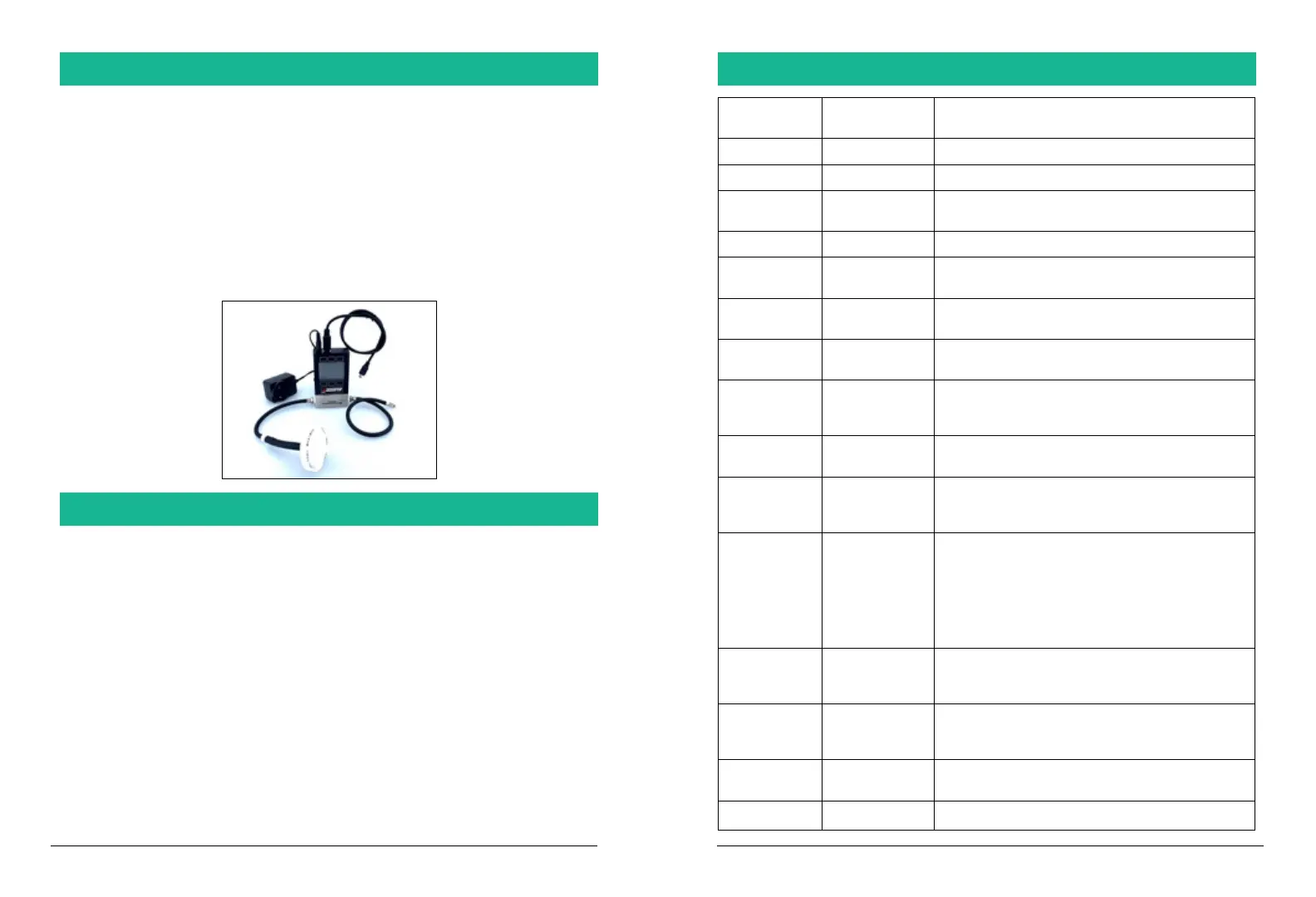

Status Codes

Code Value

Readable

status

Status Description

1 No status notications

2 Start up Instrument in sampling and measurement startup

4 Tape advance

Tape advance occurring during sampling and

measurement period

8 N/A

16

Optical

saturation

Optical saturation

32

Sample timing

error

Sample timing error

64

DualSpot

Enabled

Sampling spot 2 of DualSpot

®

loading

compensation is active

128 Flow unstable

Flow unstable during sampling and measurement

period. Flow deviates from target ow setpoint by

more than ±5%.

256 Pump drive limit

Flow out of range during sampling and

measurement period

512

Time source

manual

Time synchronization source is manual

(synchronized to application/computer time or no

GPS time is available)

1024

User skipped

tape advance

User skipped tape advance. No tape advance

occurred at start of sampling and measurements.

NOT RECOMMENDED!

SKIPPING THE AUTOMATIC TAPE ADVANCE AT

THE BEGINNING OF SAMPLING WILL IMPACT

CORRECT OPERATION OF THE DEVICE. DATA

MAY NOT BE VALID.

2048 System busy

Device stops sampling after receiving a command

via USB or serial that requires the device stop

operation.

4096 S.A. disabled

Source apportionment disabled due to

measurement conguration. Check Settings to re-

enable source apportionment calculations

8192 Tape jam

Tape is jammed. Inspect tape. Release and clamp

tape to attempt to clear the jam error.

16384 Tape at end Tape is at end. Replace tape.

Loading...

Loading...