Neither transfer or reproduction of these documents nor application or disclosure

of their content are permitted without the explicit approval of AFS.

Violations will require compensation for damages.

Page 16 of 26

7 Maintenance

Failure to maintain the device as specified in the AFS operating instructions will void the warranty or

guarantee!

7.1 Maintenance Work and Cycles for Oil and Emulsion Mist Separation

All maintenance work on a device must be performed exclusively after the device has been turned off

and by trained personnel familiar with the device.

If multiple AFS air purification devices are operating in conjunction with one another, ALL the devices

must be disabled for maintenance to be performed. Low pressure will persist throughout the entire

extraction pipe system for as long as networked devices are turned on. Where applicable, device

doors must not be opened. There is an increased risk of injury.

Maintenance cycles are to be set in accordance with the type of process and degree of contamination

in the air that is to be cleaned. The degree of pollution in the device as well as the separator elements

must be examined and then cleaned or replaced as needed.

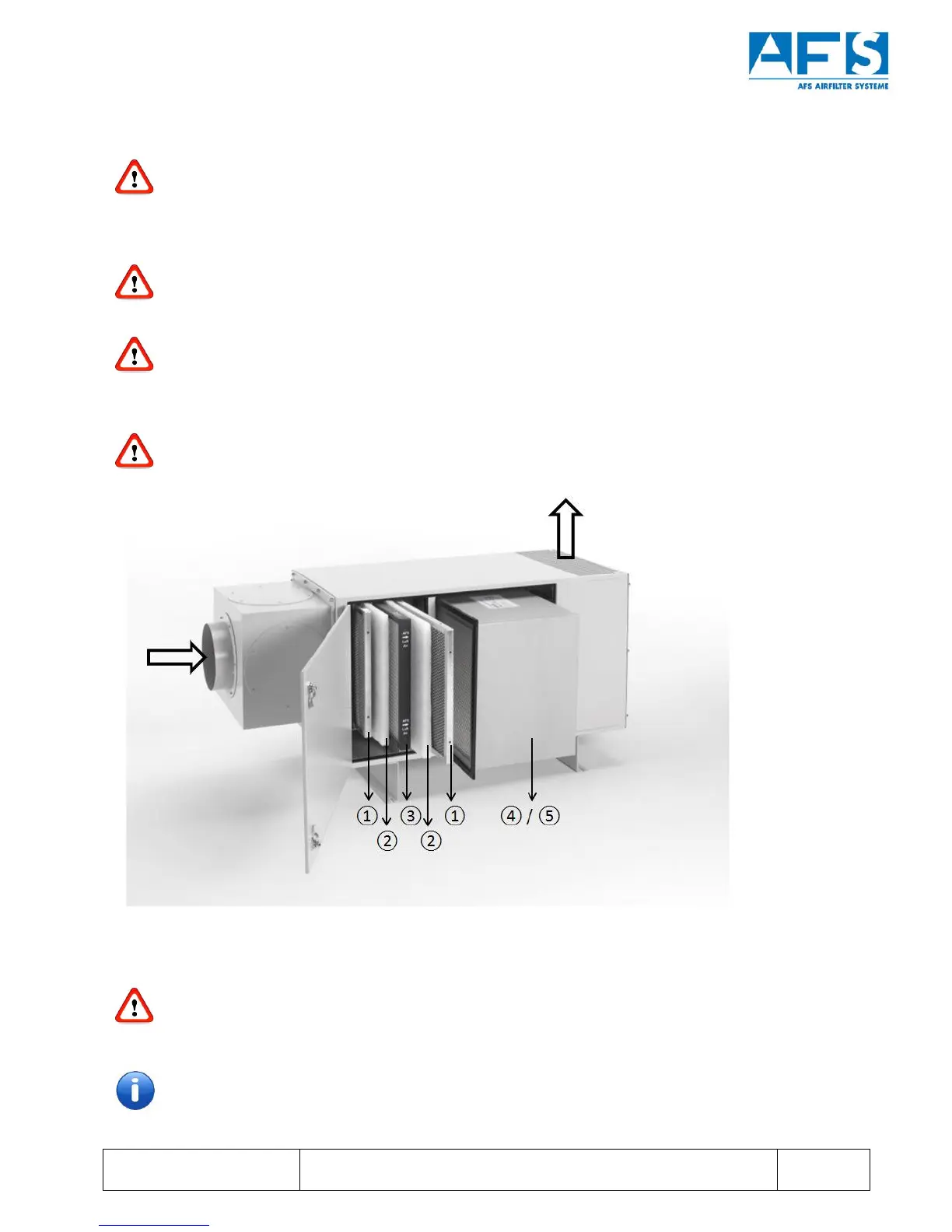

Figure 10: Filter arrangement within AFS air purification devices

Never change the order, number or installation position of the separation and filter elements as this

will render the device inoperable.

The device must only be operated with AFS-approved separation/filter elements.

The separation and filter elements may be laterally removed from the device for cleaning or

replacement.

Loading...

Loading...