Neither transfer or reproduction of these documents nor application or disclosure

of their content are permitted without the explicit approval of AFS.

Violations will require compensation for damages.

Page 20 of 26

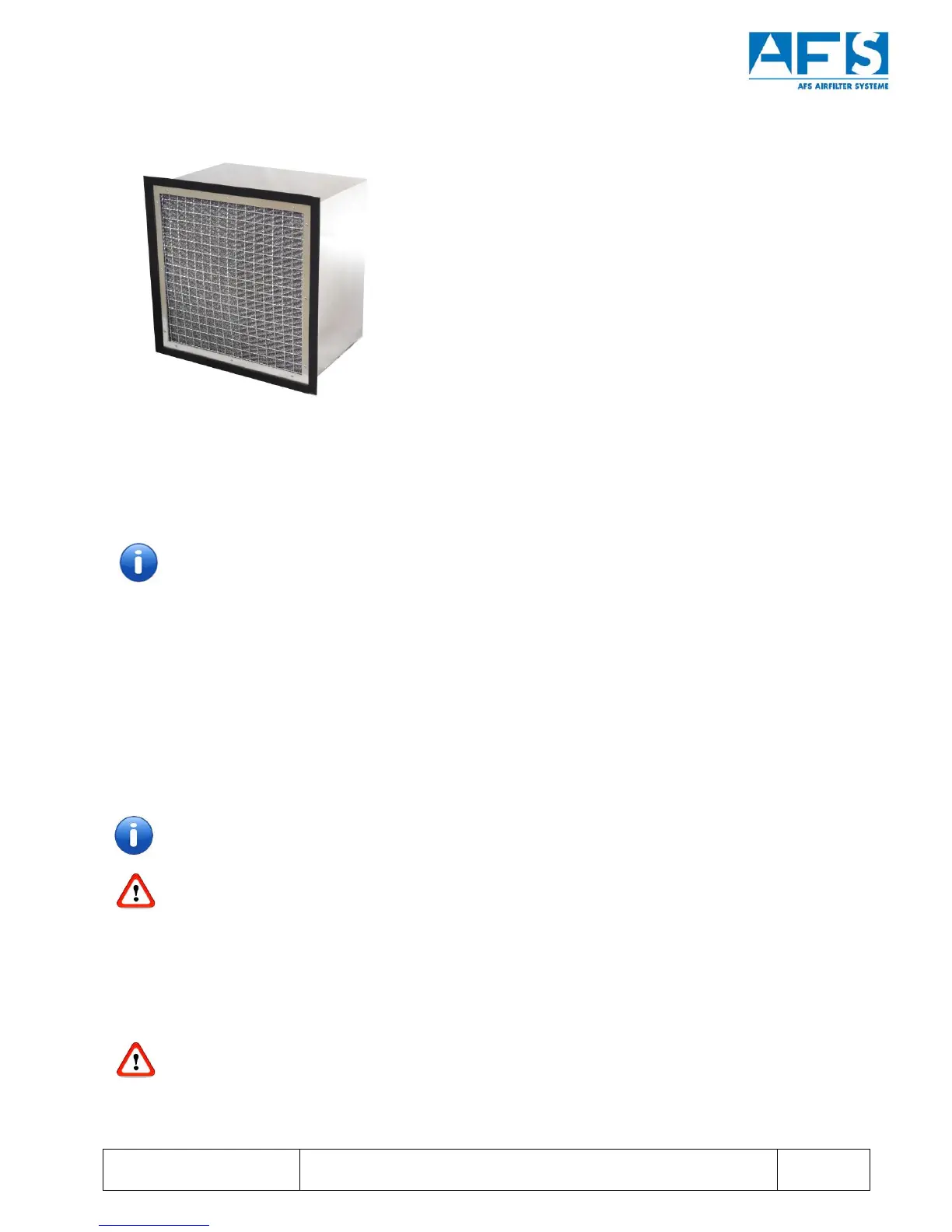

7.1.5 Metal mesh follow-up separator (pos.

…

)

Figure 15: Metal mesh follow-up separator

The following are installed as subsequent separators or post filters:

- HEPA filter H13 (Pos.

„

)

- Metal mesh follow-up separator (pos.

…

)

The separation performance of the H13 follow-up separator (see Chapter 7.1.4) is higher than that of

the metal mesh follow-up separator The metal mesh follow-up separator is not recommended for

processing installations which produce smoke and vapor.

The alternative to an H 13 post filter, an adjustable, non-wearing, corrosion-resistant metal mesh follow-up

separator, can be cleaned or washed like the metal mesh preliminary separator.

Cleaning interval: Clean when obviously clogged and dirty, i.e. if full of shavings, hardened oil, abraded

material, or grease residues.

And at least every 4 weeks.

Directions: Use hot water and a grease-removing cleaning agent with a high-pressure cleaner or

in a component washing system.

To replace a dirty post filter, undo the M6 screws on the terminal strips so as to allow the follow-up

separator to be pulled out.

Parts will have oil and coolant lubricant residue. Wastewater must be disposed of properly and in an

ecologically responsible manner.

7.1.6 Ventilator (pos.

†

)

The ventilator motor and wheel are largely maintenance-free. If the separation and filter elements are not

maintained or not properly maintained, there is a risk that the ventilator motor will overheat.

In the event of a malfunction, please contact AFS.

The ventilator wheel in any AFS air purification device must not be disassembled under any

circumstances.

Loading...

Loading...