Neither transfer or reproduction of these documents nor application or disclosure

of their content are permitted without the explicit approval of AFS.

Violations will require compensation for damages.

Page 24 of 26

7.3.2 MPR Connections

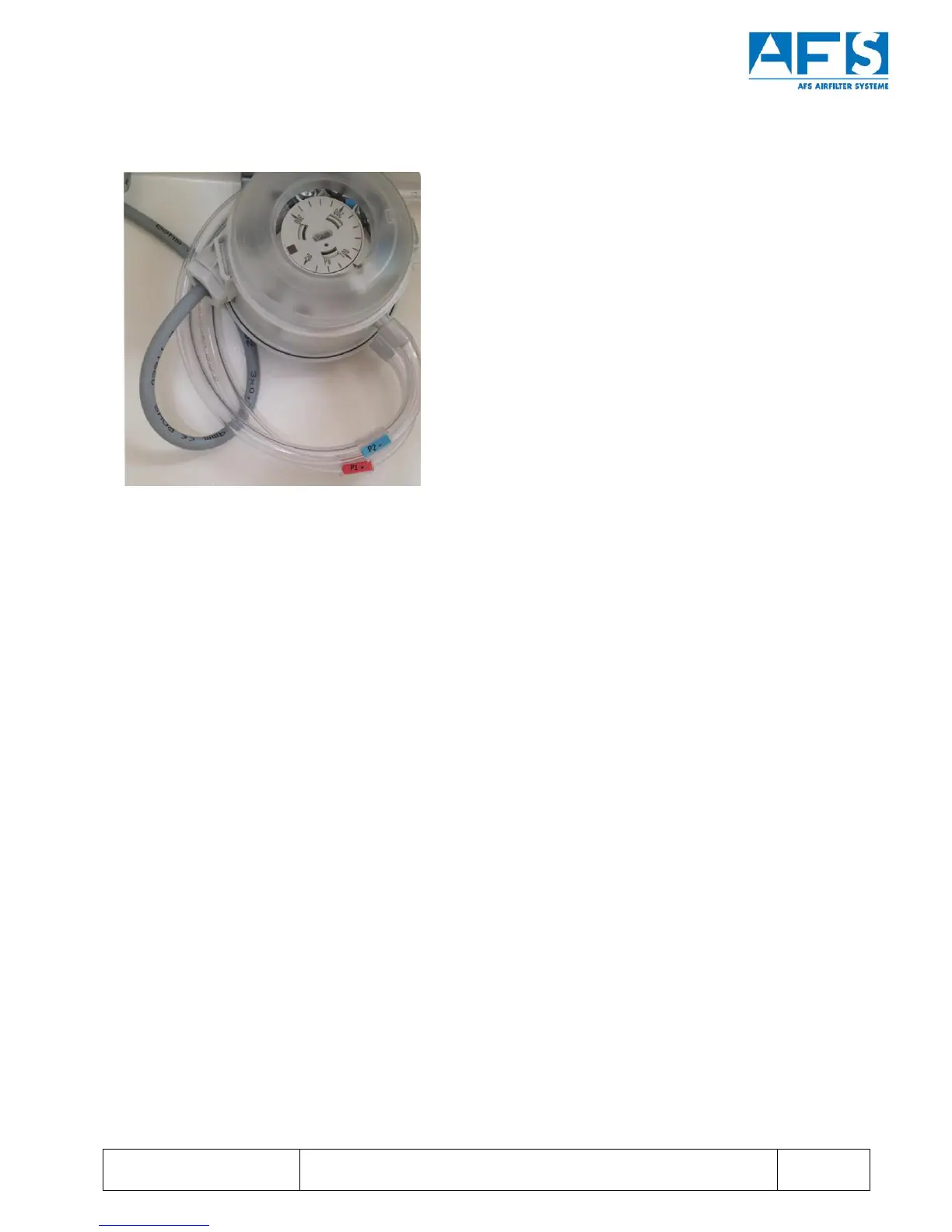

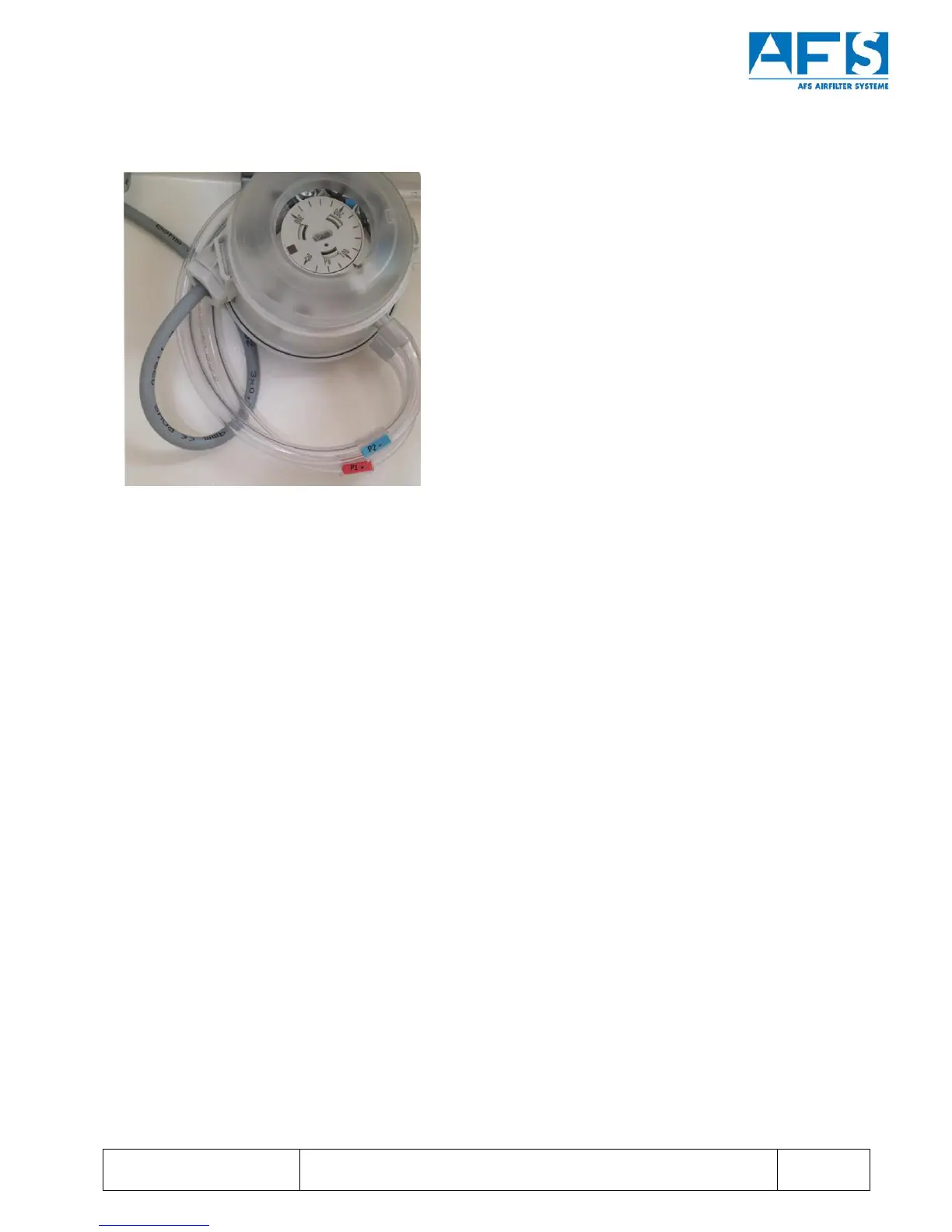

The MPR is to be connected as in Figure17. The hoses must not be buckled.

Figure17: Connection of MPR P1+ and P2-

7.3.3 MPR Error Diagnostics

If the MPR still indicates that the volumetric flow rate through the AFS device is below the minimum despite

new filters or maintenance work, then the following steps should be carried out:

· Check motor rotation direction (see chapter 5.4.1)

· Check MPR switch position: Must be set to 100 Pa.

If the signal is still on, then:

· Remove all filters other than the Longlife separator

· Close the device again and turn the system back on

· Wait a little while until the differential pressure has adjusted

· If the signal is no longer on, install new or cleaned filters and separators as indicated in Chapter 5.6.

However, if the signal remains, then the unwanted volumetric flow rate is not being caused by the filters or

separators. Other possible error sources might be:

· Blocked intake port or induction pipe

· Clogged pressure transducer

· Bent pressure transducer pipes (run in a path to the inner top edge of the device)

· Blocked exhaust vent or exhaust air pipe

· Overall pressure loss through the entire system (from intake to exhaust) too great

· Ventilator does not work in the desired area of operation

· Frequency converter (where available) adjusted incorrectly

· Ventilator speed too low

· MPR connected incorrectly

Loading...

Loading...