O r i g i n a l I n s t r u c t i o n M a n u a l f o r A F S A i r P u r i f i c a t i o n D e v i c e s

f o r R e m o v i n g O i l a n d E m u l s i o n M i s t

Produced By:

Version:

Valid from:

U. Burkhardt

1.05

01/11/2016

Neither transfer or reproduction of these documents nor application or disclosure

of their content are permitted without the explicit approval of AFS.

Violations will require compensation for damages.

Page 22 of 26

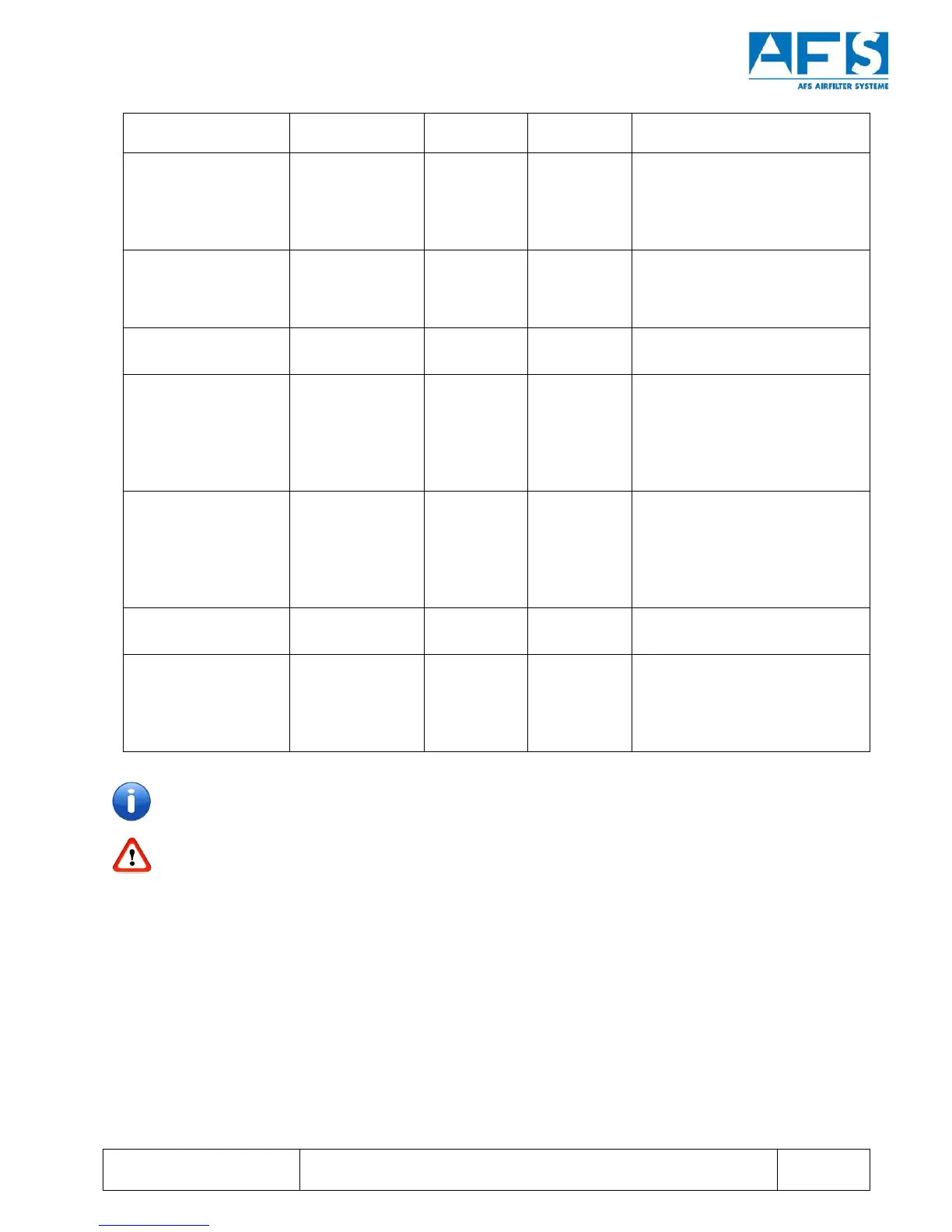

Type of

clogging/dirt

Inspection

interval

Cleaning

interval

Directions for

cleaning/replacements

•

Preliminary separator

metal mesh

Weekly

At least every

4 weeks

Clean with hot water and a grease

removing cleaning agent with a

pressure washer or in a component

‚

Preliminary filter

fleece

Weekly

At least every

4 weeks

Replace with a conventional grade

G3 filter fleece with a fleece

-cleaning Weekly As needed

Replace filter Undo M6 screws on

When fitting the new filter, the

rubber sealing strip must be on the

suction side (in the terminal area)

and the filter bags vertical.

…

Follow-up separator

metal mesh

(alternative to

„

)

Weekly

At least every

4 weeks

Clean the filter. To do so,

undo M6 screws on terminal strips.

Clean with hot water and a grease

removing cleaning agent with a

In the event of a malfunction,

Weekly

At least every

4 weeks

Once clean, the siphons have to be

filled with coolant lubricant again;

7.1.7.

We recommend that a set of replacement filters be kept on hand so that old ones may be replaced

quickly when necessary and so that the system can be put back into operation immediately.

Parts will have oil or coolant lubricant residue. Wastewater or components must be disposed of

properly and in an ecologically responsible manner.

Loading...

Loading...