3

PlateLoc Thermal Microplate Sealer

Optimizing the sealing quality

Reference for Optimal Thermal Microplate Sealing

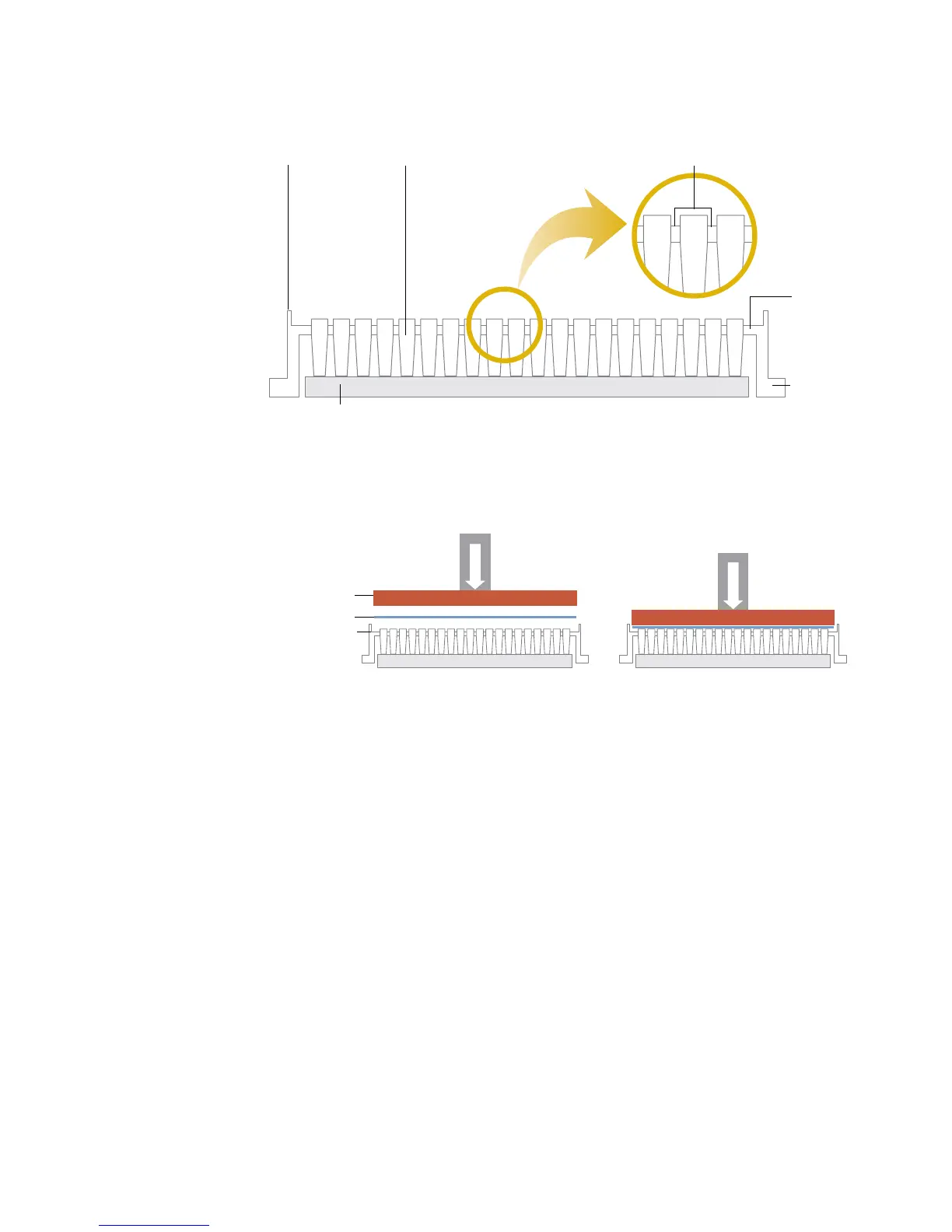

Figure 1 Microplate physical features and nomenclature

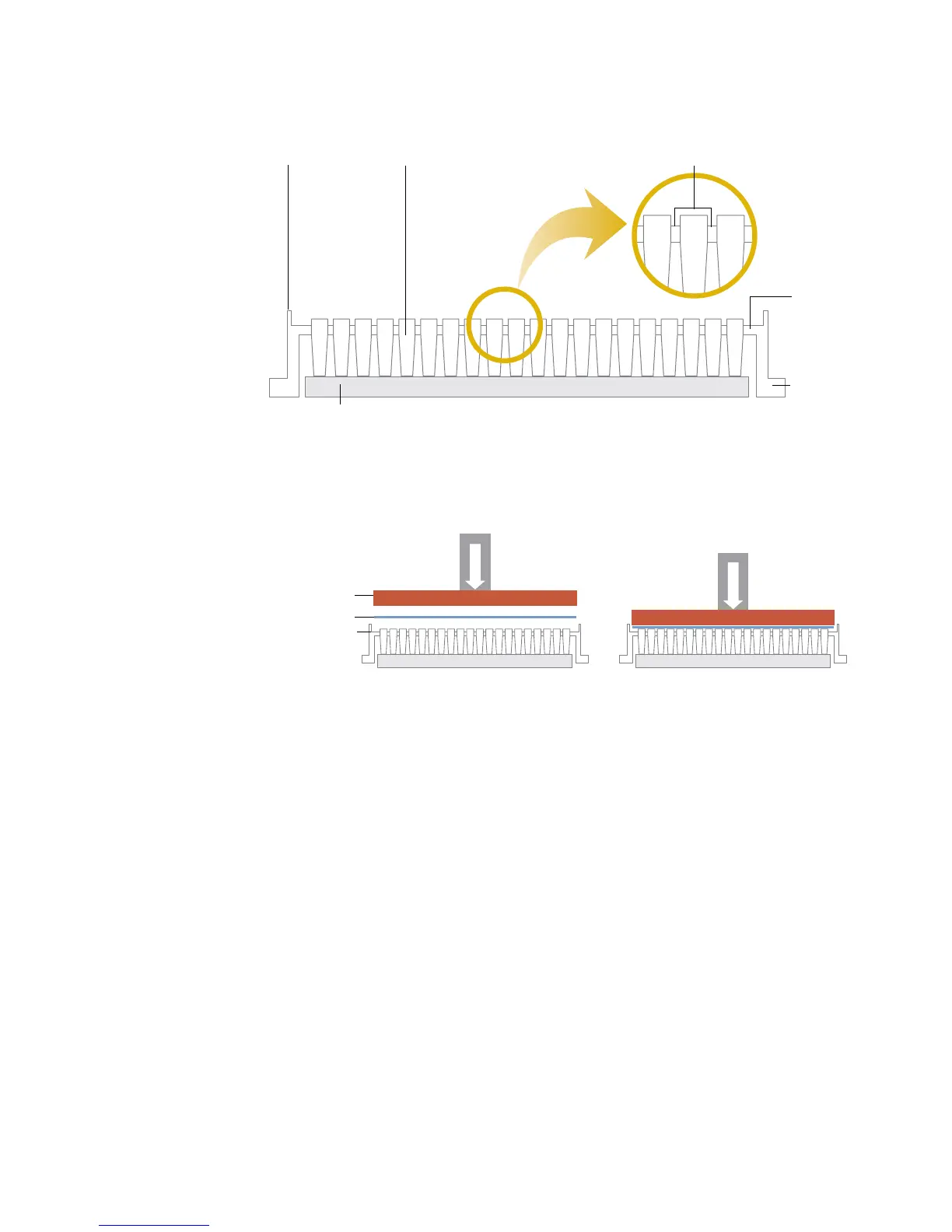

Figure 2 Left: Pneumatics drive the hot plate down to the microplate surface. The hot plate can

sens

e and automatically adjust for variations in microplate height. Seals are applied using

pressure and heat. Right: If the microplate has a raised rim that is higher than the chimney height

around its perimeter, the hot plate must fit within the rimmed area so that the hot plate can make

uniform contact with the seal and all sample wells simultaneously.

Microplate material

For the best sealing results:

• Use polypropylene microplates because they are the easiest to seal

ef

fectively and reliably.

• Avoid acrylic microplates because they are not compatible with thermal

mi

croplate sealing.

• If the microplates are flexible and tend to bend and move during the

s

ealing process, use adapter trays to stabilize the microplate position on

the plate stage. For example, place a flexible 96- well polypropylene

microplate on top of a 96- well polystyrene microplate to provide positional

support. Agilent Technologies also offers an adapter tray for PCR

microplate support.

Raised rim around

perimeter (if any)

Sample well

Skirt

Plate

surface

Chimney: Top of well rises

beyond microplate surface

Insert

HOT PLATE

HOT PLATE

Microplate with

raised rim

Sealing film

Hot plate

Loading...

Loading...