PlateLoc Thermal Microplate Sealer

Optimizing the sealing quality

4 Reference for Optimal Thermal Microplate Sealing

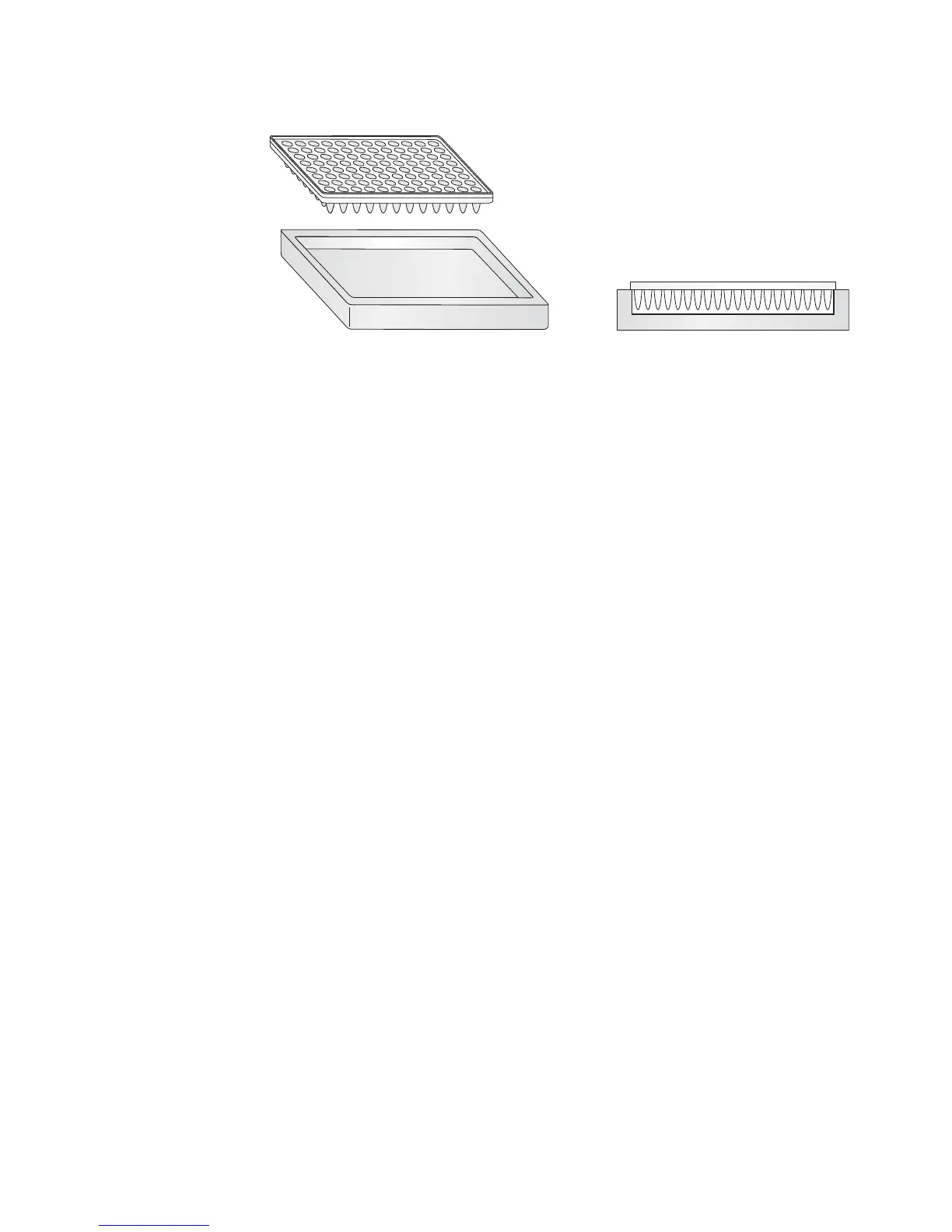

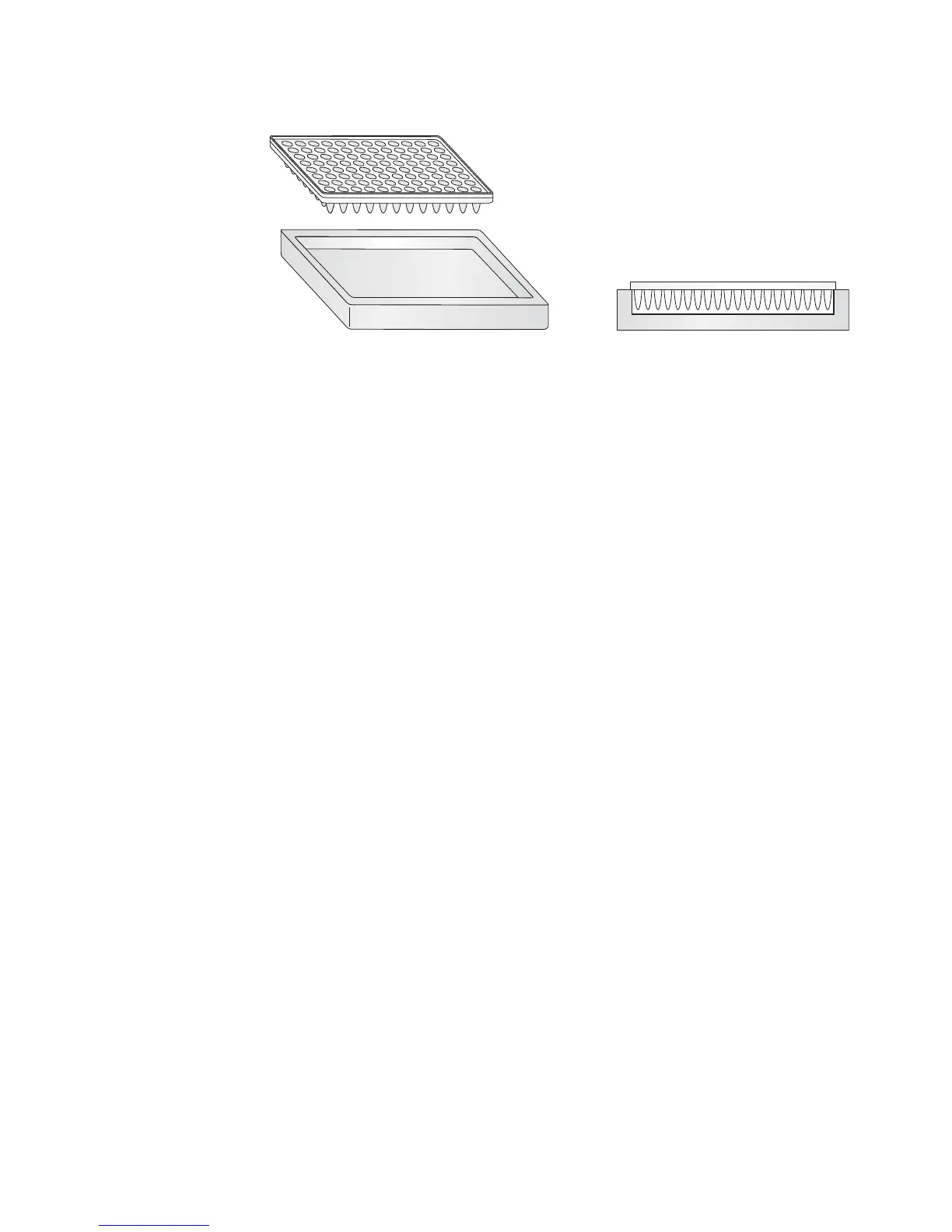

Figure 3 Left: Microplate and PCR Plate Support. Righ

t: Microplate in PCR Plate Support.

Microplate make and model

• Be aware that similar microplates made from the same material but from

different manufacturers may perform differently.

• Evaluate every microplate make and model to ensure consistent results.

Microplate features

Be aware of design features on the top surface of the microplate that can

significantly affect the quality of the seal.

• The microplate lacks raised chimneys and it has

molded branding or

legends, such as the manufacturer’s name or logo, or the sample locating

legends (for example A, B, C, . . . and 1, 2, 3 . . .) close to the tops of the

wells (close enough so that seal touches or covers the imprint).

• Tooling marks or manufacturing aids, such as circular depressions

(som

etimes with branching) caused by ejection pins or part of the molding

process. Gaps or gutters may not only prevent binding of the seal, but may

actually facilitate cross- contamination of liquid samples.

Sealing parameters

The following parameters can be adjusted to optimize the sealing results:

•Temperature

•Time

Perform optimization tests to determine the best

values to use. For details, see

“Optimizing the sealing parameters (temperature versus time)” on page 10.

Insert thickness

Choose the right insert to support the microplate and ensure uniform sealing.

A set of four inserts are presently shipping with every PlateLoc Sealer, and a

special insert is available for Labcyte microplates.

Loading...

Loading...