5

PlateLoc Thermal Microplate Sealer

Optimizing seal parameters

Reference for Optimal Thermal Microplate Sealing

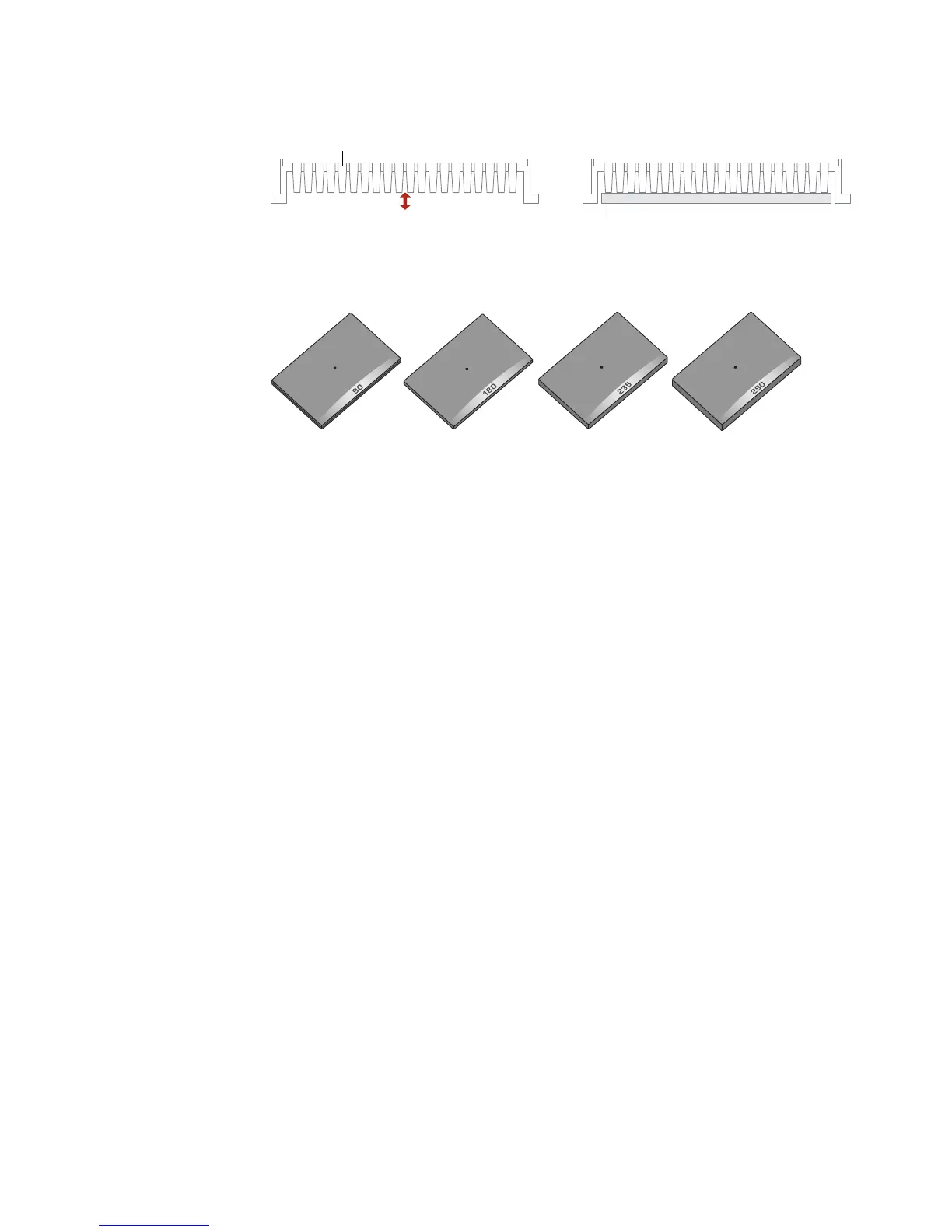

Figure 4 Microplate without and with insert

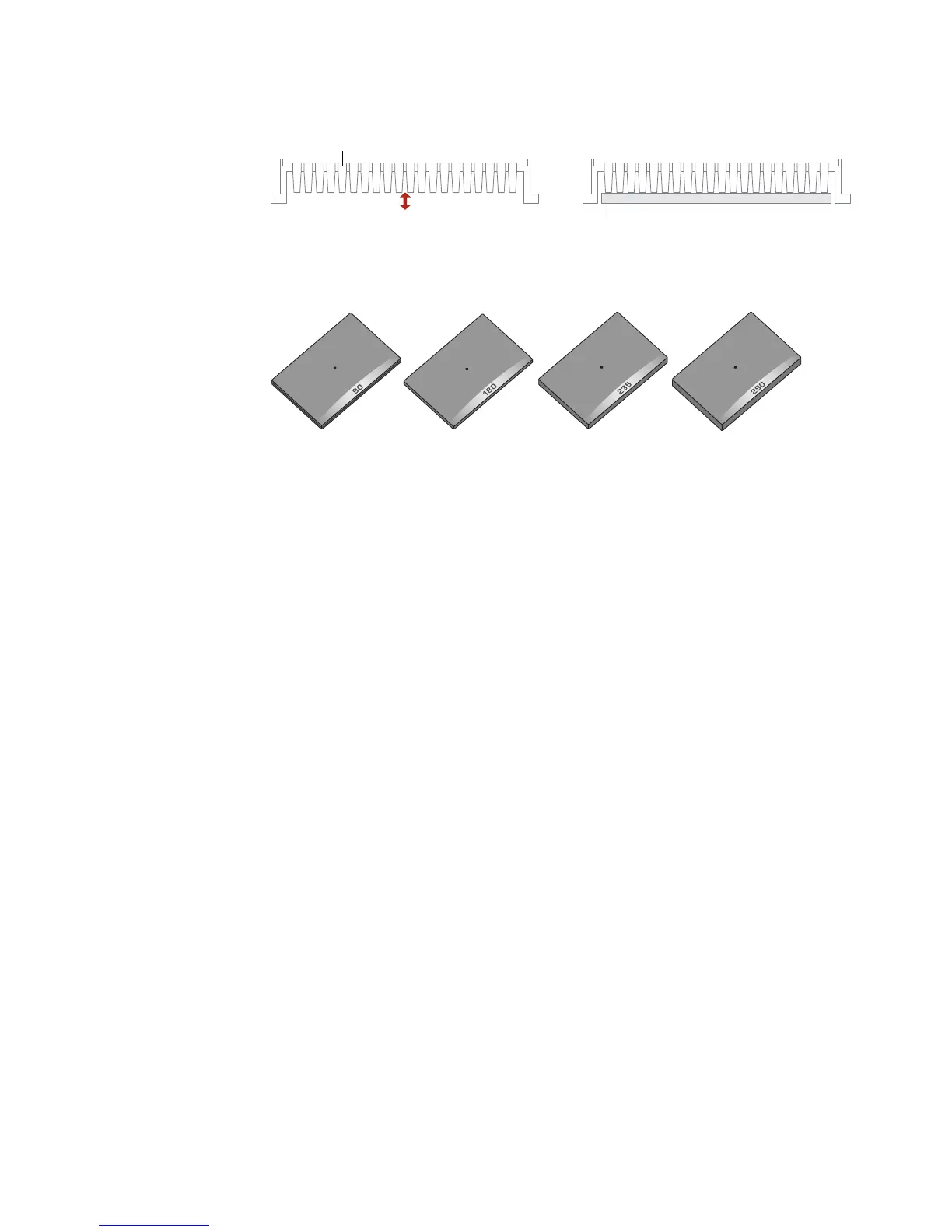

Figure 5 Standard inserts. The number on the inserts in

dicates the

thickness of the metal pad

(for example, 180 means 0.180 in thick). Note: The 90 insert has a 0

.90-in metal pad with foam

padding on the microplate-facing side and is used with microplates that require flexible support.

Seal material

Different seal materials have different properties and can produce different

results. Perform optimization tests to determine the best seal to use.

Optimizing seal parameters

About this section

This section explains how to inspect the seal quality and, if necessary, how to

adjust the sealing parameters to improve the seal. Before proceeding, download

a copy of the PlateLoc Seal Selection Guide from the Agilent Technologies

website at http://www.chem.agilent.com/

en-us/products/instruments/automation/

microplatehandling/plateloc/pages/default.aspx.

Apply a seal using the time and temperature starting points suggested in the

PlateLoc Sealer Selection Guide, for your chosen seal and microplate material.

Examine the well impressions made on the seal. The pattern and quality of

these impressions is a good indicator of seal quality.

Evaluating the seal

After the seal cycle is finished, wait for the microplate to cool down enough so

that it is safe to handle (10 to 30 seconds). Do not handle the microplate

immediately after the seal cycle is finished. The sealed microplate might be

hot.

Note: Pier

ceable seals might permanently adhe

re to the microplate. Do not wait

too long or the seals will be difficult to remove.

Remove the microplate from the PlateLoc Sealer. Carefully peel off the seal

material

by lifting one of the corners of the seal as shown in Figure 6.

Bend direction

Microplate insert

Wells

Loading...

Loading...