4 ©Copyright Agrispread September 2014

830 Belt Spreader

Setting Spinner Speeds and Rear Deflectors

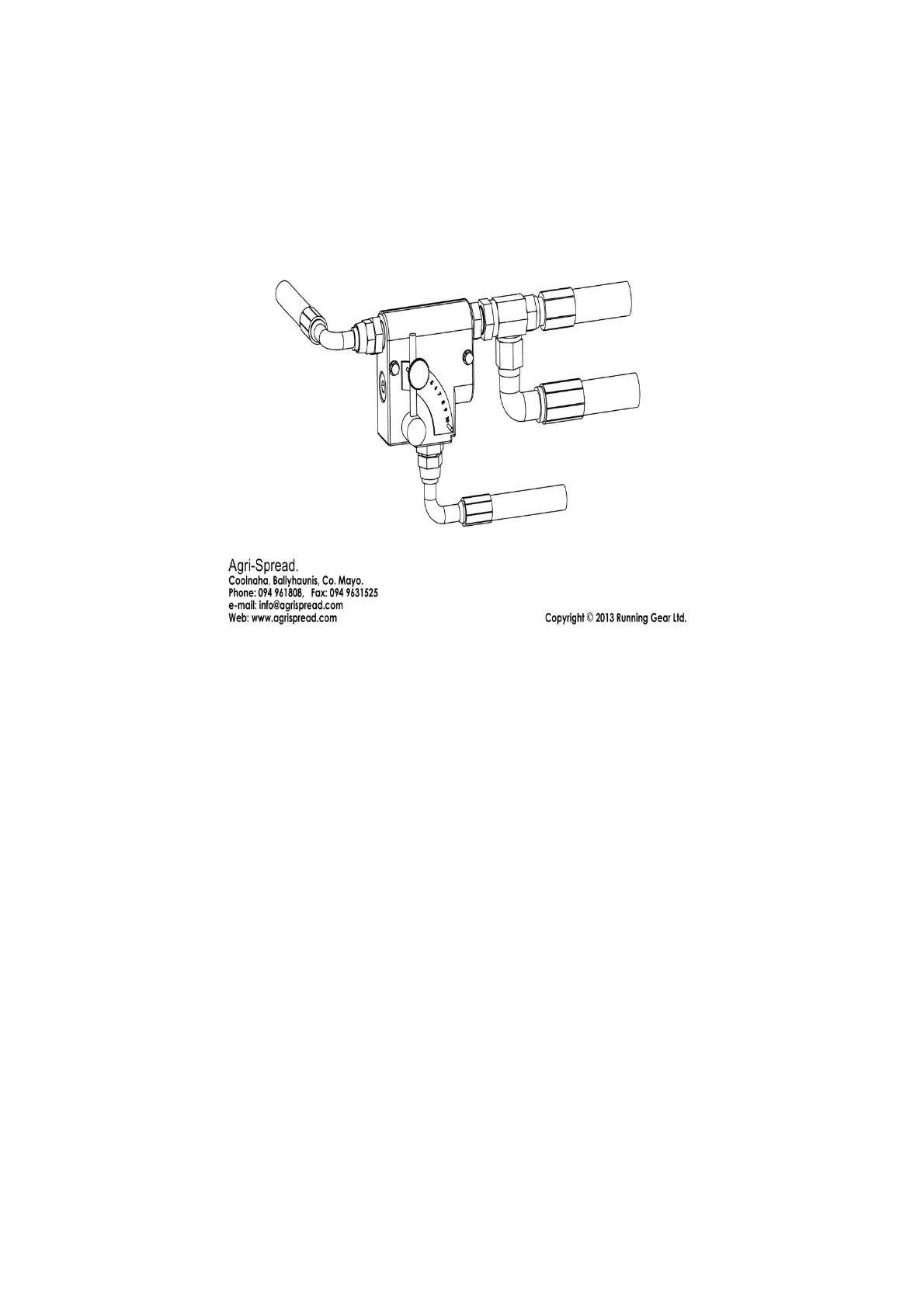

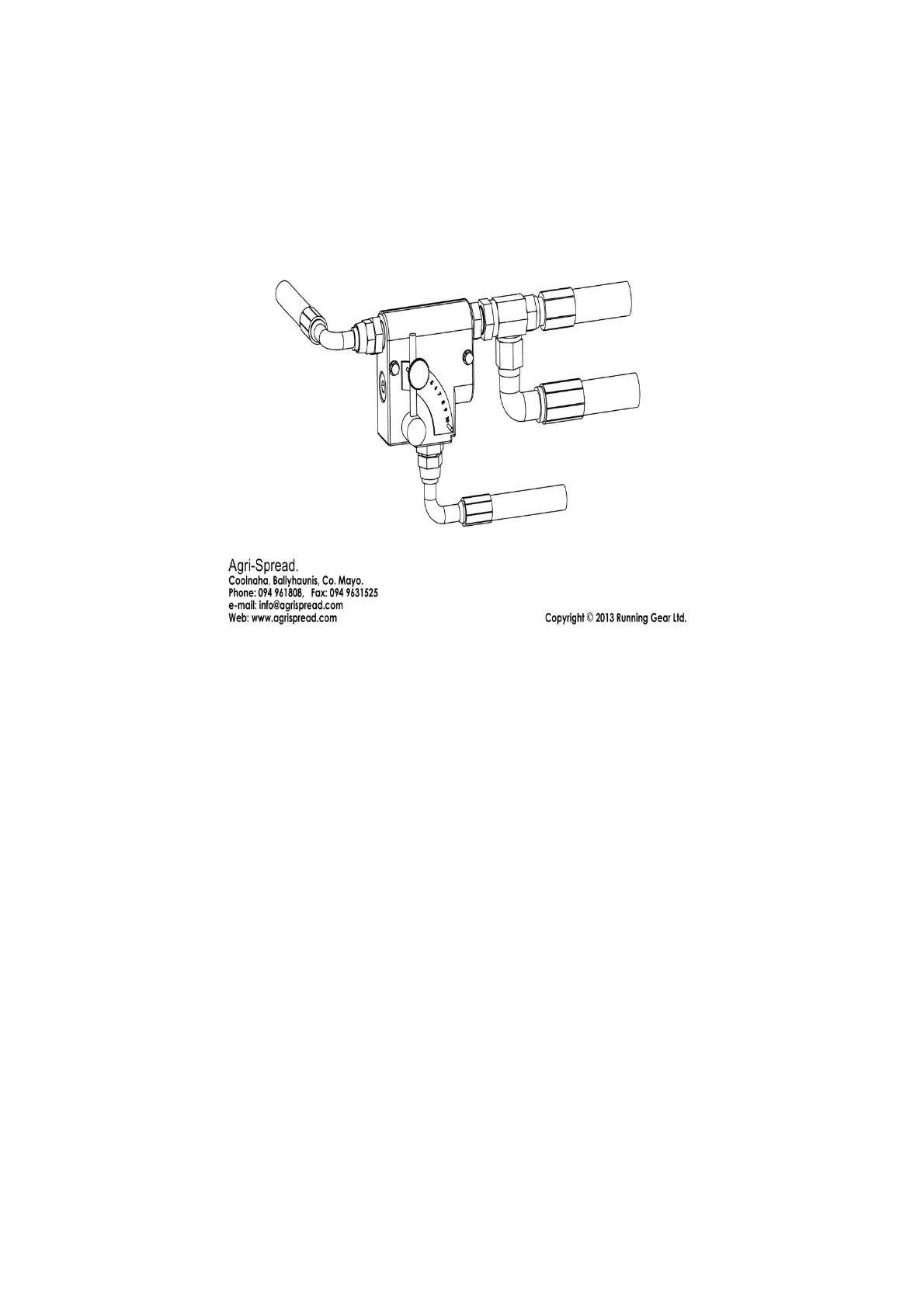

Spinner Speed is the most important factor in achieving an accurate spread pattern. The

spinner speed is adjusted by altering the control on the valve at the front of the machine

(shown in Figure 1 below). Guideline spinner speeds for various different materials are given

in Table 1 : Recommended Spinner Speeds For Spreading on page 38.

Figure 2: Spinner Flow Control Valve

When setting spinner speeds ensure the engine of the tractor is running at the same R.P.M. as

it will normally be operating in the field and make sure that the oil is warmed up to its normal

operating temperature. Always monitor the spinner speed by watching the tachometer when

operating the spreader as an error of 50 R.P.M. on spinner speed will result in a deterioration

of the spread pattern. If the spinner speed is too high there will be too much material behind

the spreader. If the spinner speed is too slow there will be too little material behind the

spreader.

It is sometimes necessary to alter the angle of the rear deflectors to lighten the spread behind

the machine and throw the material more into the centre of the pattern. This is shown in the

table on the following page along with the spinner speeds for sample materials and is

expressed in the following manner.

WARNING: NEVER ADJUST THE DEFLECTORS WHILE THE

SPINNERS ROTATING.

Loading...

Loading...