© Glenco Air & Power Pty Ltd

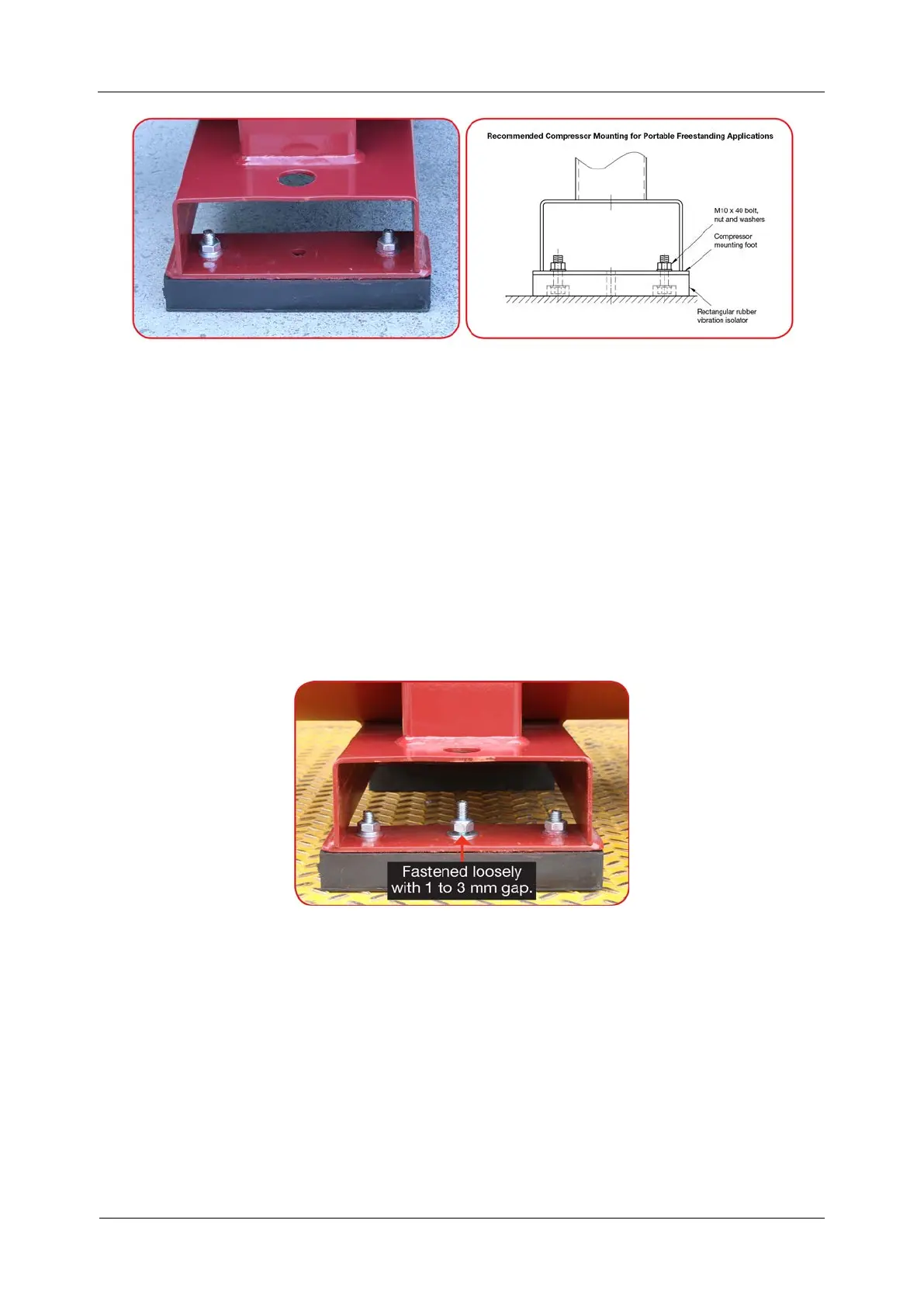

Figure 5-1 Freestanding Foot-Mounting Arrangement

The compressor can be bolted to a firm, level foundation that is strong enough to support its weight

such as a concrete floor or alternatively secured to a vehicle chassis or tray for mobile applications.

Flexible vibration isolators must be used between the compressor and mounting surface. Do not bolt

uneven feet tightly to the foundation as this will cause excessive stress on the air receiver tank. Use

metal shims to pack under any “short” feet, if necessary, which is most often due to the floor surface

not being perfectly level rather than the mounting feet being uneven. There are three common

methods used for such bolted-down, foot-mounting installations:

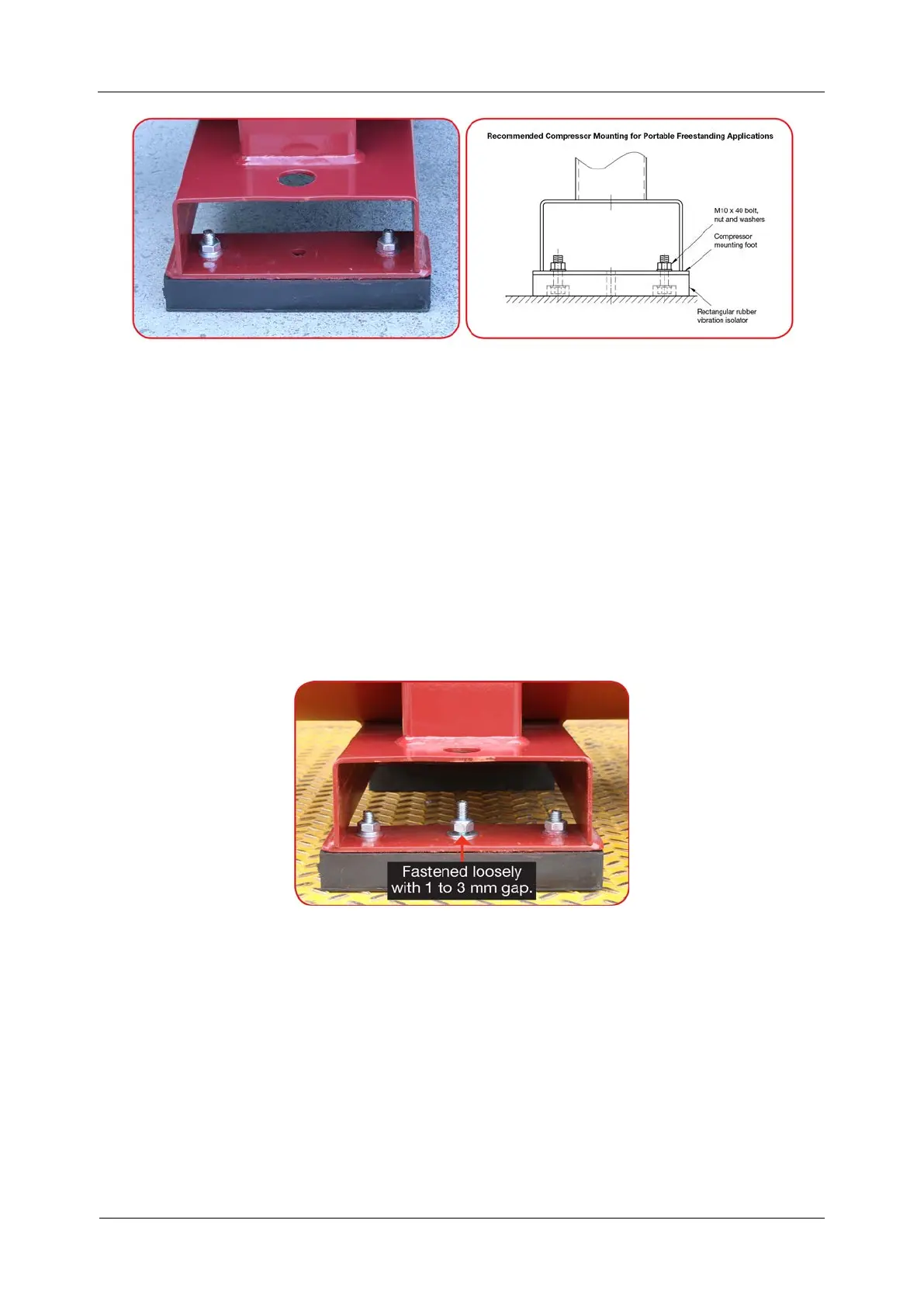

(a) The basic method as shown in Figure 5-2 has the compressor being bolted-down loosely

through the factory supplied vibration isolators with a gap of 1 to 3 mm to allow for vertical

movement. One should apply thread lock adhesive such as Loctite® or use a nylon insert lock

nut to prevent the central fastener from unscrewing.

Figure 5-2 Basic Bolted-Down, Foot-Mounting Arrangement

(b) A preferred method as shown in Figure 5-3 is for the compressor set to be bolted-down

loosely through the factory supplied compression and rebound vibration isolators with a gap

of 1 to 3 mm to allow for vertical movement. One should apply thread lock adhesive such as

Loctite® or use a nylon insert lock nut to prevent the central fastener from unscrewing.

Loading...

Loading...