© Glenco Air & Power Pty Ltd

8.0 Troubleshooting

8.1 Precautions

Before performing any inspection, test or repair work on the compressor, isolate and tag-out the

power supply or disconnect the petrol engine’s spark plug, turn off the fuel supply (if engine-driven),

carefully release any residual air pressure from the air receiver tank and any connected air hoses or

piping, and close the air outlet valve or disconnect the outlet air hose. And, if possible, allow the unit

to cool down if it has been running.

Please refer to the troubleshooting guide shown in Table 8-1 for assistance with diagnosing and

repairing any problem that might occur with your air compressor. Whilst many of the tasks can be

undertaken by a mechanically proficient person with access to proper tools, all electrical work must

by undertaken by a licensed electrician.

It is recommended for your convenience that this troubleshooting guide be consulted prior to

contacting an Airmac dealer or Glenco Air & Power Pty Ltd for advice. Additional technical

information is available online for download at www.glencoairpower.com.au.

Please refer also to the separate instruction manual for troubleshooting of the petrol or diesel

engine, if fitted.

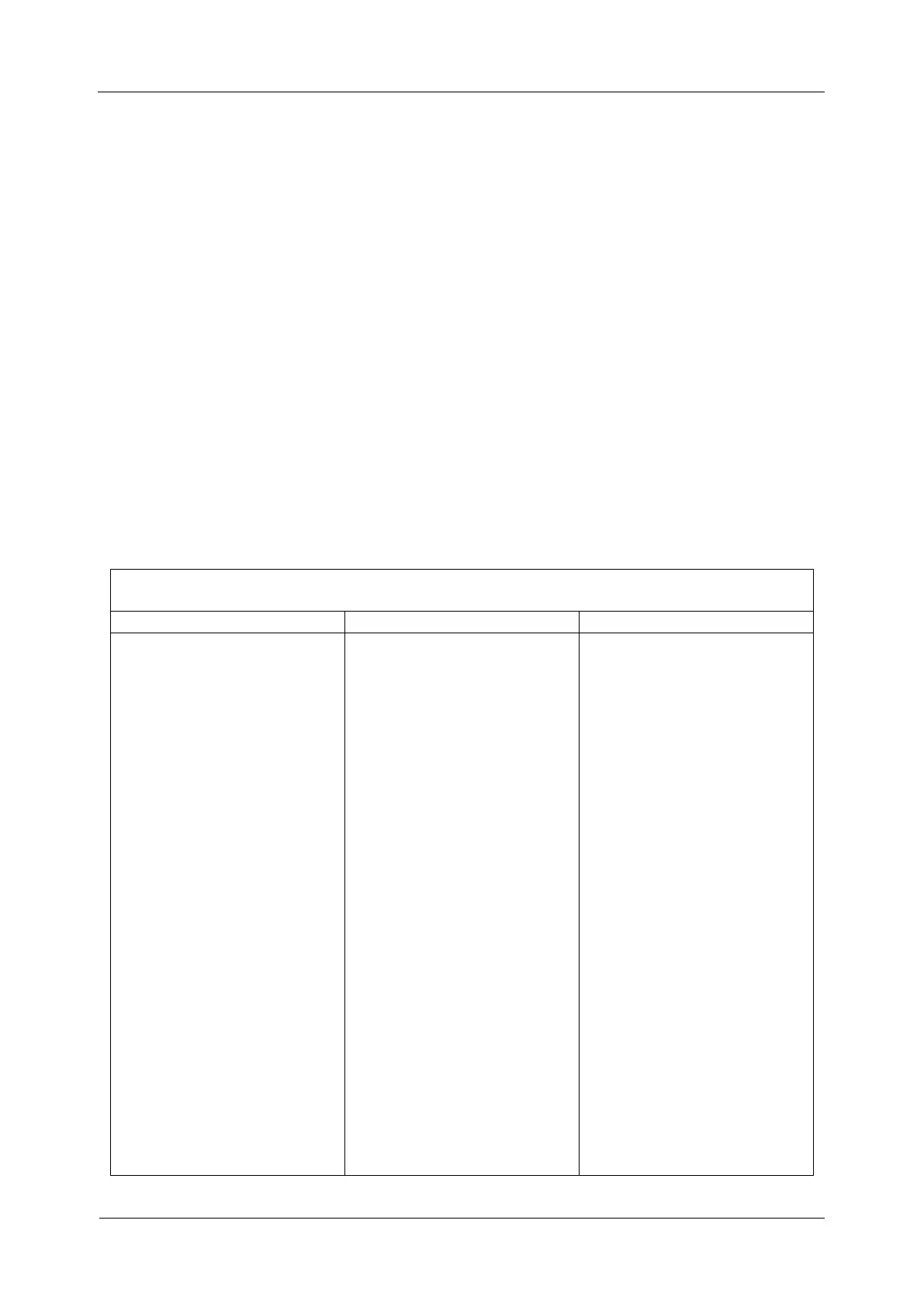

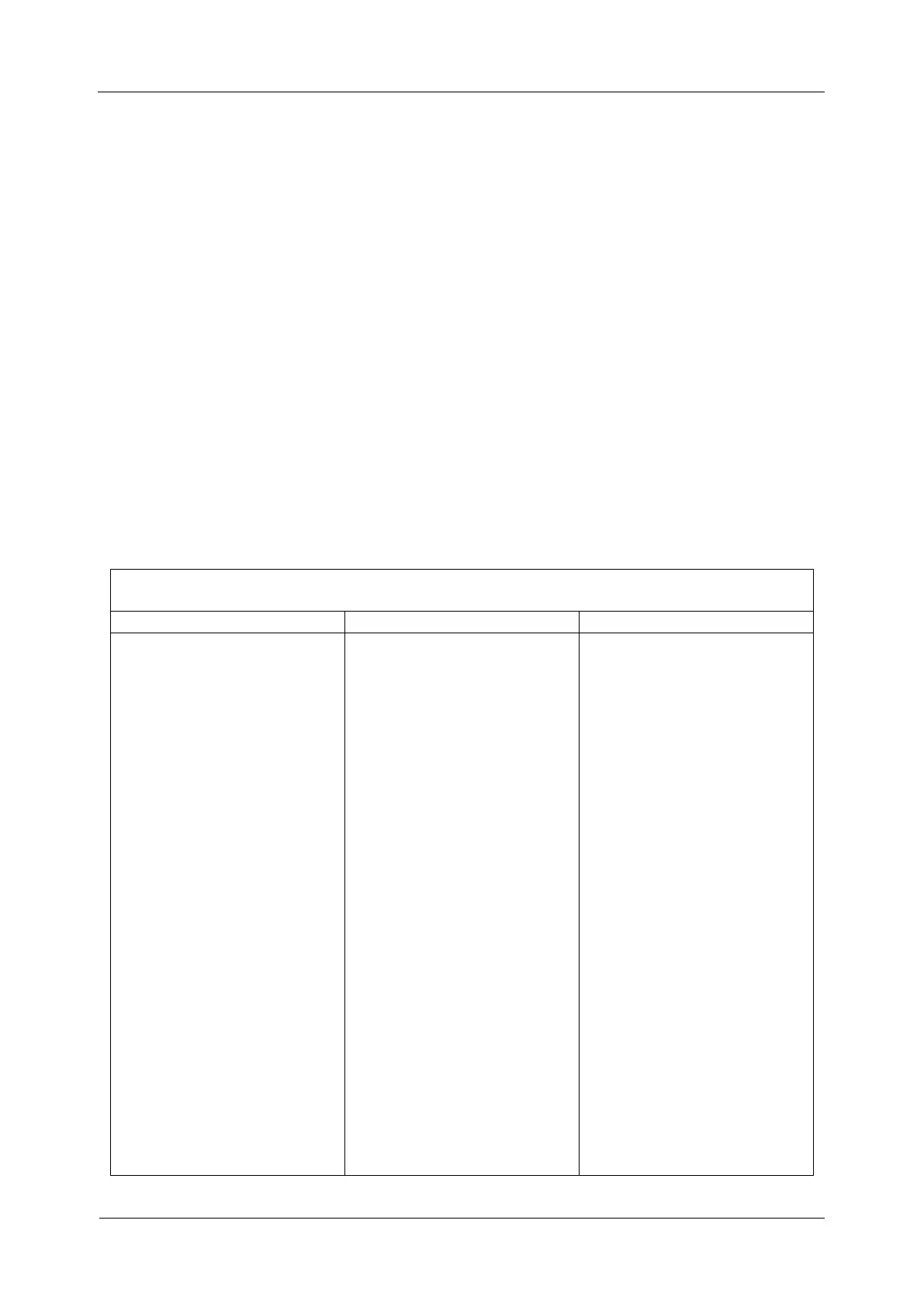

Table 8.1

Troubleshooting Chart

Motor will not start, runs

slowly or repeatedly trips out

overload protection.

1. Pressure switch not turned

on.

2. Air receiver tank pressure

above cut-in pressure.

3. No voltage at the pressure

switch.

4. No voltage at the electric

motor (faulty pressure

switch or star-delta

starter).

5. No voltage on one or two

phases of 415 V supply.

6. Low supply voltage.

7. Use of extension lead.

8. 240 V: Thermal overload

switch on motor tripped.

1. Turn on pressure switch.

2. Nil (no fault).

3. Check electricity supply

including all fuses, circuit

breakers, switches and

wiring.

4. Repair or replace pressure

switch or star-delta starter.

5. Check voltage on all three

phases of 415 V supply.

6. Check no load and full load

supply voltage. Upgrade

power supply circuit if

required. Disconnect any

other electrical devices on

the same supply circuit.

7. Do not use extension lead.

Use longer air hose with

larger diameter.

8. 240 V: Allow motor to cool

down and manually reset

Loading...

Loading...