© Glenco Air & Power Pty Ltd

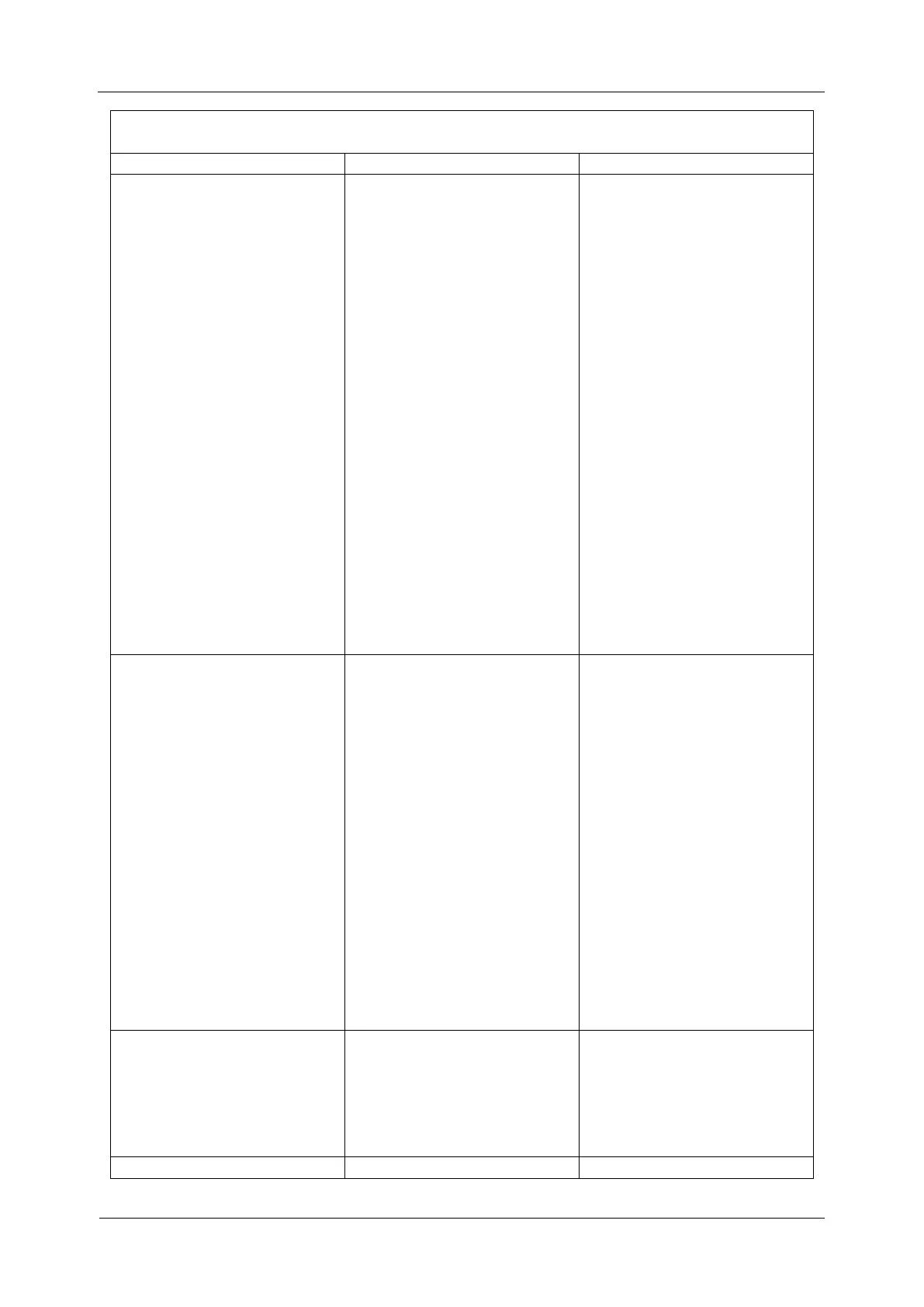

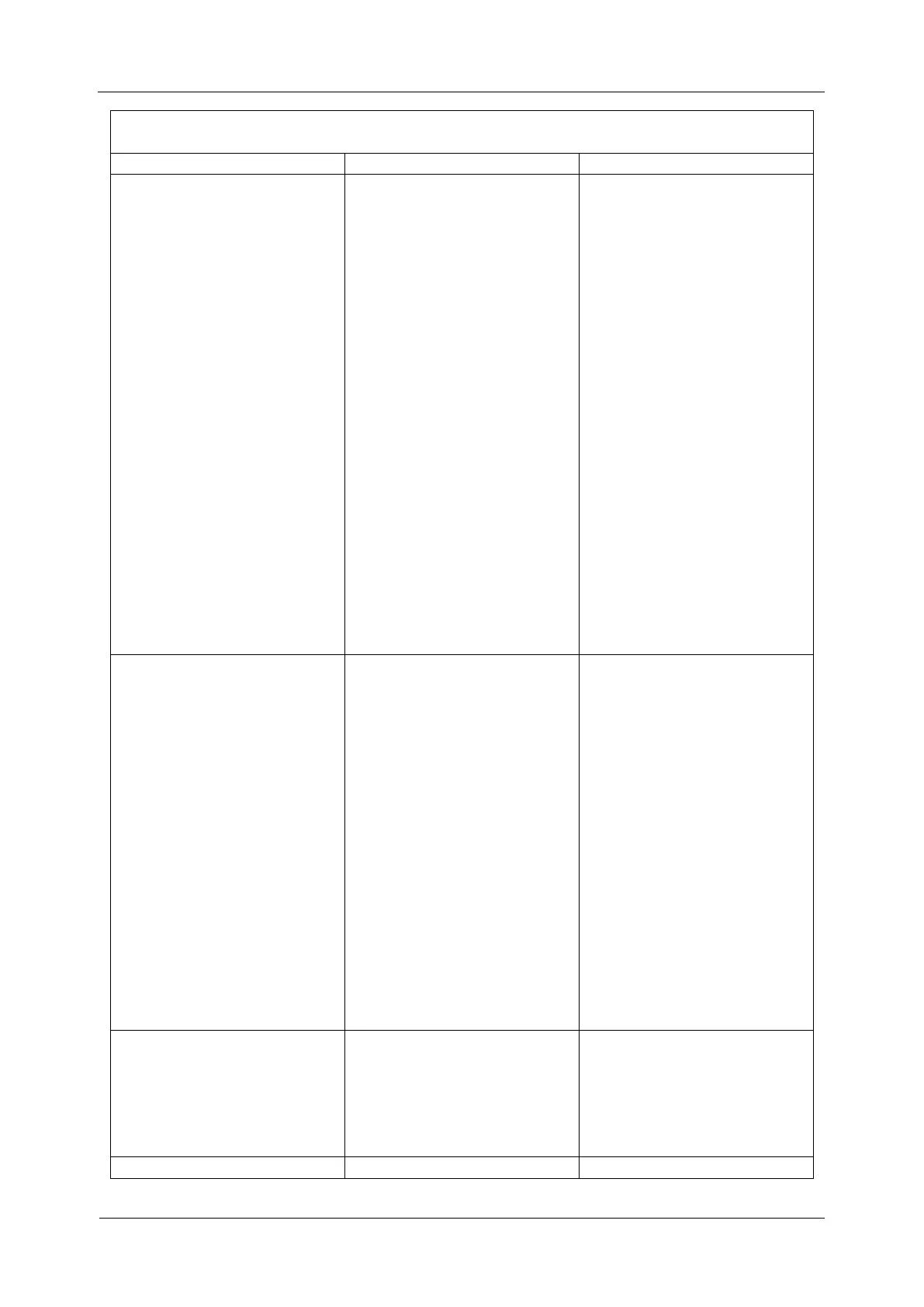

Table 8.1

Troubleshooting Chart

pressure.

capacity.

2. Air leaks.

3. Blocked or dirty inlet air

filters.

4. Loose engine or motor

pulley, loose compressor

pump pulley, or loose /

worn V-belts.

5. Head unloaders not fully

retracting (usually

indicated by air blowing

out from air filter inlets).

6. Damaged or worn

compressor pump valves

or blown cylinder head

gaskets.

7. Damaged or worn piston

rings, pistons or cylinders.

8. Faulty non-return valve.

compressor(s).

2. Tighten, refit or replace

leaking connections or

components.

3. Clean or replace air filter

elements.

4. Tighten or replace pulleys

as required, check

alignment and adjust V-

belt tension.

5. Repair or replace head

unloaders.

6. Replace compressor pump

valves or cylinder head

gaskets.

7. Replace components or

entire compressor pump.

8. Repair or replace non-

excessively hot (and possibly

melts air filter enclosures).

1. Incorrect direction of

rotation.

2. Ambient temperature too

high or insufficient

ventilation.

3. Low oil level.

4. Excessive duty cycle.

5. Damaged or worn

compressor pump valves

or blown cylinder head

1. Check compressor pulley

turns anti-clockwise

(looking onto pulley).

Change electric motor

connections if incorrect.

2. Reduce ambient

temperature or improve

ventilation (e.g. move

further away from walls or

other equipment).

3. Add oil.

4. Reduce air demand or use

larger or additional

compressor(s).

5. Replace compressor pump

valves or cylinder head

gaskets.

Excessive duty cycle (> 75%

loading ratio or continuous

loading times > 10 minutes).

1. Air demand is too high.

2. Air leaks.

1. Reduce air demand or use

larger or additional

compressor(s).

2. Tighten, refit or replace

leaking connections or

Excessive cycling between

1. Maximum cycling occurs

1. Nil (no fault). Cycling will

Loading...

Loading...