© Glenco Air & Power Pty Ltd

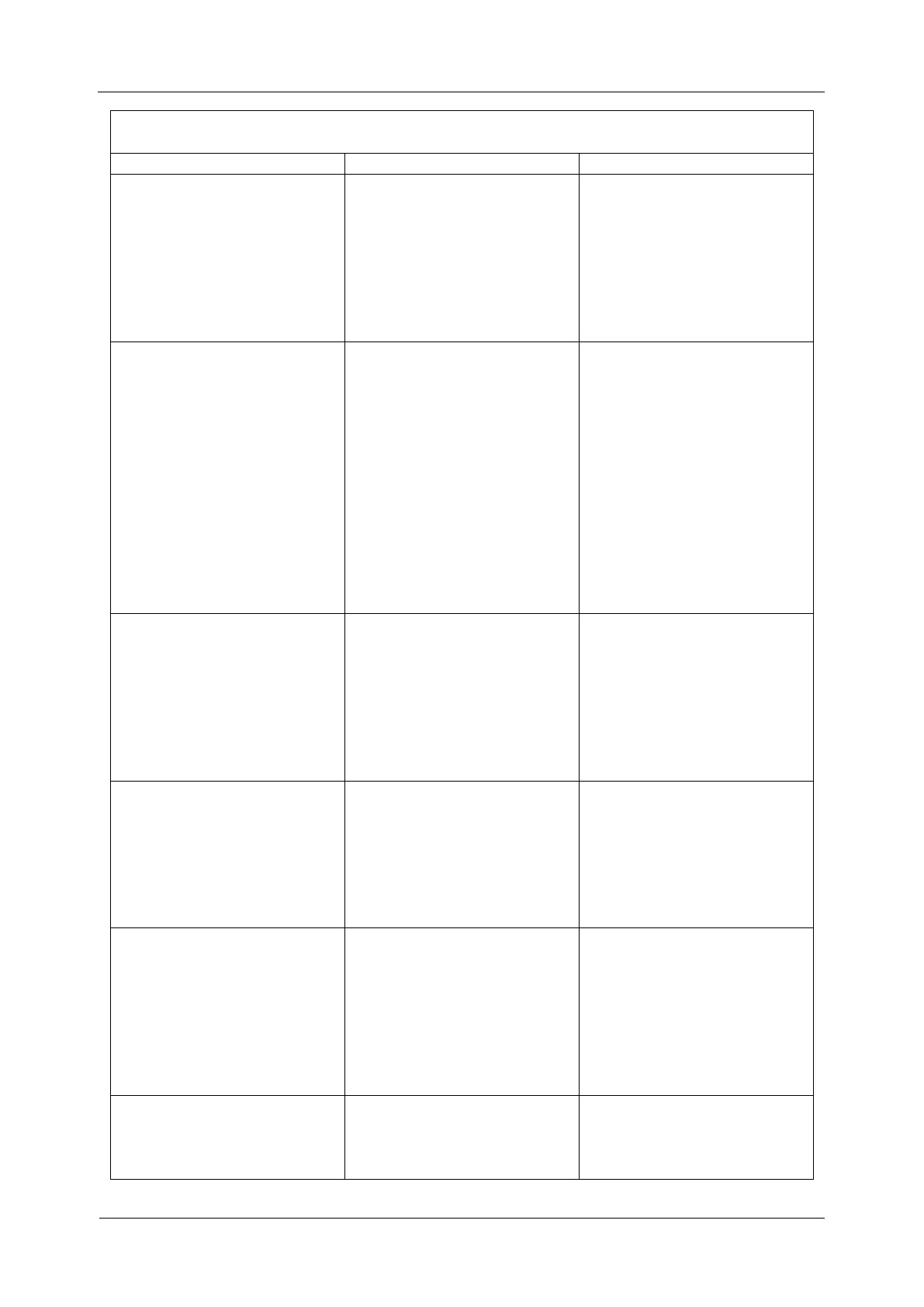

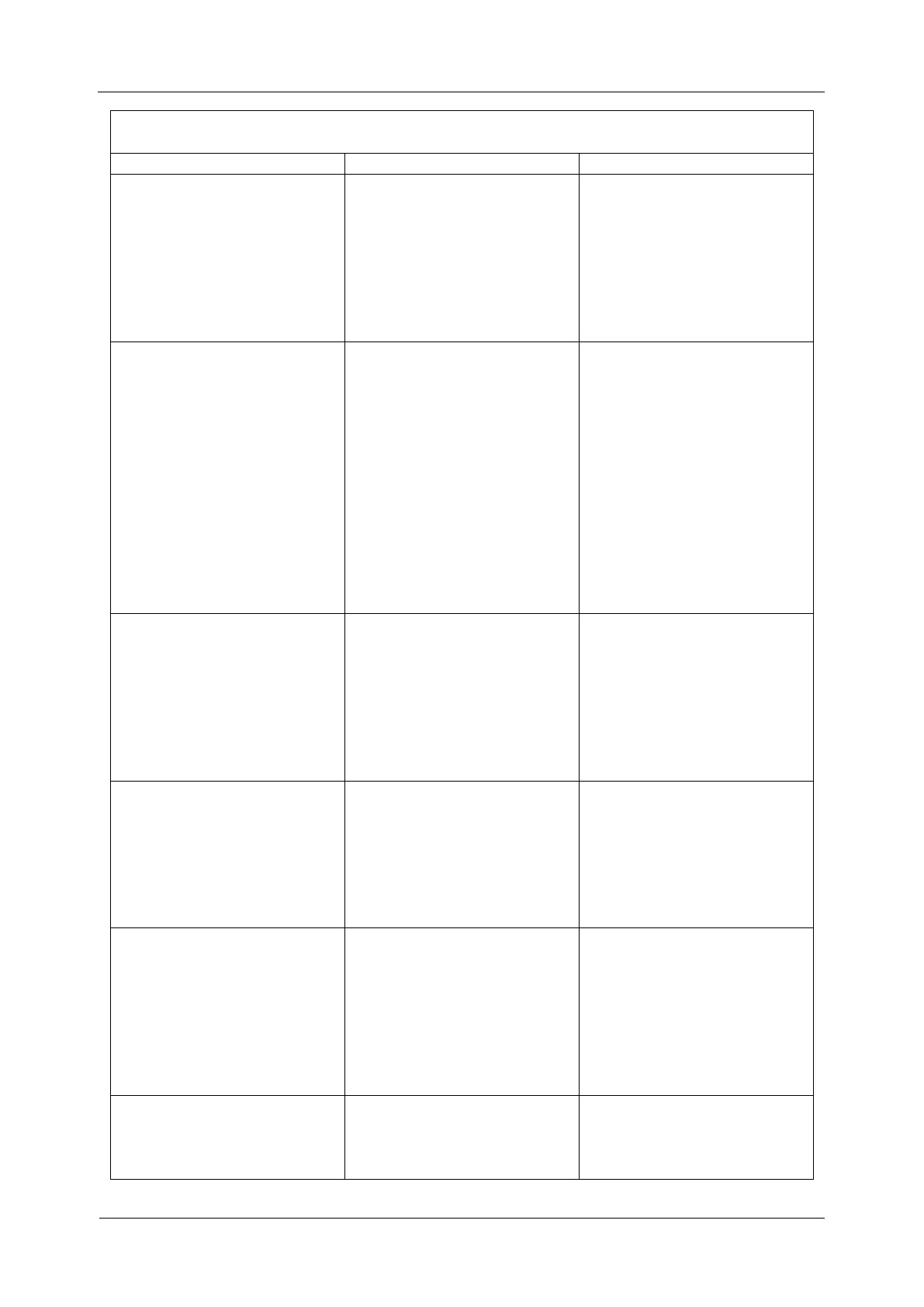

Table 8.1

Troubleshooting Chart

pumping mode and unloading

or off mode.

when air demand is at 50%

of compressor output.

2. Air leaks.

3. Excessive condensate in air

decreased or increased

compressed air demand.

2. Tighten, refit or replace

leaking connections or

components.

3. Drain air receiver tank.

Excessive oil in discharge air.

1. Blocked or dirty inlet air

filters.

2. Overfilled with oil.

3. Low oil viscosity.

4. Excessive duty cycle.

5. Blocked or damaged

crankcase breather.

6. Damaged or worn intake

valves, piston rings, pistons

1. Clean or replace air filter

elements.

2. Drain oil down to high level

mark.

3. Replace with correct oil.

4. Reduce air demand or use

larger or additional

compressor(s).

5. Clean or replace crankcase

breather.

6. Replace components or

entire compressor pump.

1. No fault. This is normal

operation. Condensate

quantity will increase with

duty cycle and humidity.

1. Install dryer or filter in

discharge line. Install

automatic tank drain valve

or manually drain air tank

more often. Revise

distribution piping system

to ensure proper

Compressor does not switch

off and safety valve discharges.

1. Faulty or incorrectly set

pressure switch or pilot

valve.

2. Faulty safety valve.

3. Note: Use tank pressure

gauge to help diagnose

1. Adjust or replace pressure

switch or pilot valve.

2. Replace safety valve.

Low suction or air blowing out

at air filter inlets during

pumping mode.

compressor pump inlet

valves or blown cylinder

head gaskets.

2. Head unloaders not fully

retracting (usually

indicated by air blowing

out from air filter inlets).

1. Replace compressor pump

inlet valves or cylinder

head gaskets.

2. Repair or replace head

unloaders.

No short discharge of air from

the pressure switch after

reaching cut-out pressure or

being manually switched off.

1. Faulty pressure switch

unloader valve.

2. Blocked or damaged

1. Replace unloader valve or

complete pressure switch.

2. Clean or replace unloading

Loading...

Loading...