© Glenco Air & Power Pty Ltd

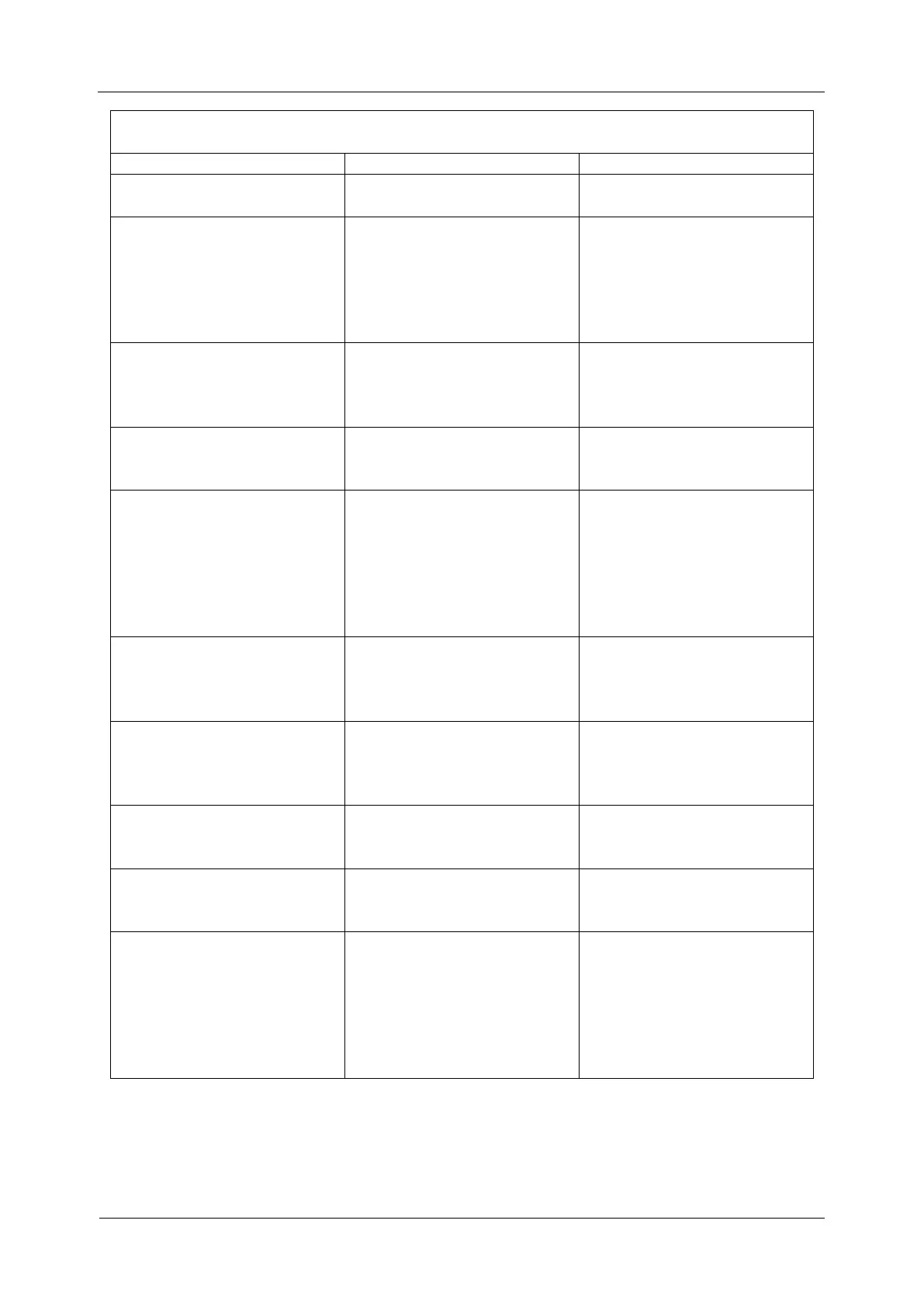

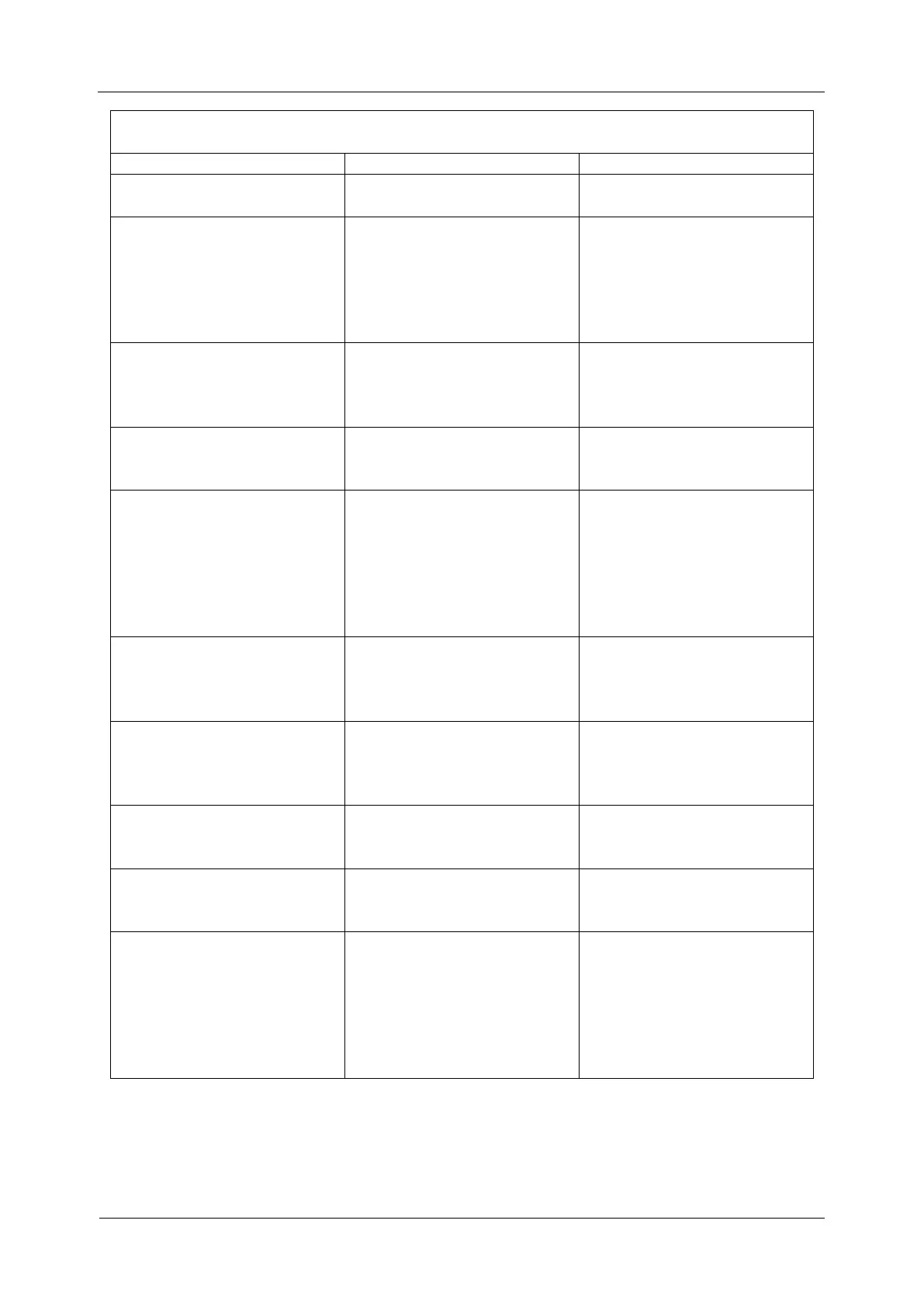

Table 8.1

Troubleshooting Chart

3. Blocked or faulty non-

return valve.

3. Clean, repair or replace

non-return valve.

Short initial discharge of air

from the 240 Volt pressure

switch during pumping mode

after starting with nil or low

pressure in the air receiver

1. Correct function of the

“soft start” pressure switch

unloading valve to reduce

motor starting current.

Continuous discharge of air

from the pressure switch after

reaching cut-out pressure or

being manually switched off.

1. Faulty non-return valve.

1. Repair or replace non-

return valve.

Continuous discharge of air

from pressure switch during

1. Faulty pressure switch

unloader valve.

1. Replace unloader valve or

complete pressure switch.

Air receiver tank does not hold

pressure when compressor is

off and discharge outlet valve

is closed.

1. Faulty non-return valve.

2. Faulty head unloaders.

3. Air leaks.

1. Repair or replace non-

return valve.

2. Repair or replace head

unloaders.

3. Tighten, refit or replace

leaking connections or

Engine stalls when compressor

changes from unloading mode

to pumping mode.

1. Engine idle speed too low.

2. Engine throttle control not

opening fully.

1. Increase engine idle speed.

2. Adjust or replace throttle

control.

Engine stalls when compressor

changes from pumping mode

to unloading mode.

1. Engine idle speed too low.

2. Head unloaders not fully

actuating.

1. Increase engine idle speed.

2. Repair or replace head

unloaders.

External oil discharge from

compressor pump.

1. Tighten, refit or replace

leaking connections or

Oil appears “milky” in sight

glass.

1. Water contamination in

oil.

compressor to less damp

Oil appears black in sight glass.

1. Graphite carry-over from

cast iron material (initial oil

fill only).

2. Oil dirty or overheated

(initial or subsequent oil

fill).

2. Replace oil and check for

compressor pump

overheating.

Loading...

Loading...