To replace valves :—

After cleaning valve guide bores with

rag smear each valve stem with clean

oil and reverse procedure above.

IMPORTANT NOTE :—

If for any reason valve springs are re-

moved from their fixing block it is

important to see that upon replace-

ment the spring with narrow spaced

prongs is entered into the block from

the chamfered end.

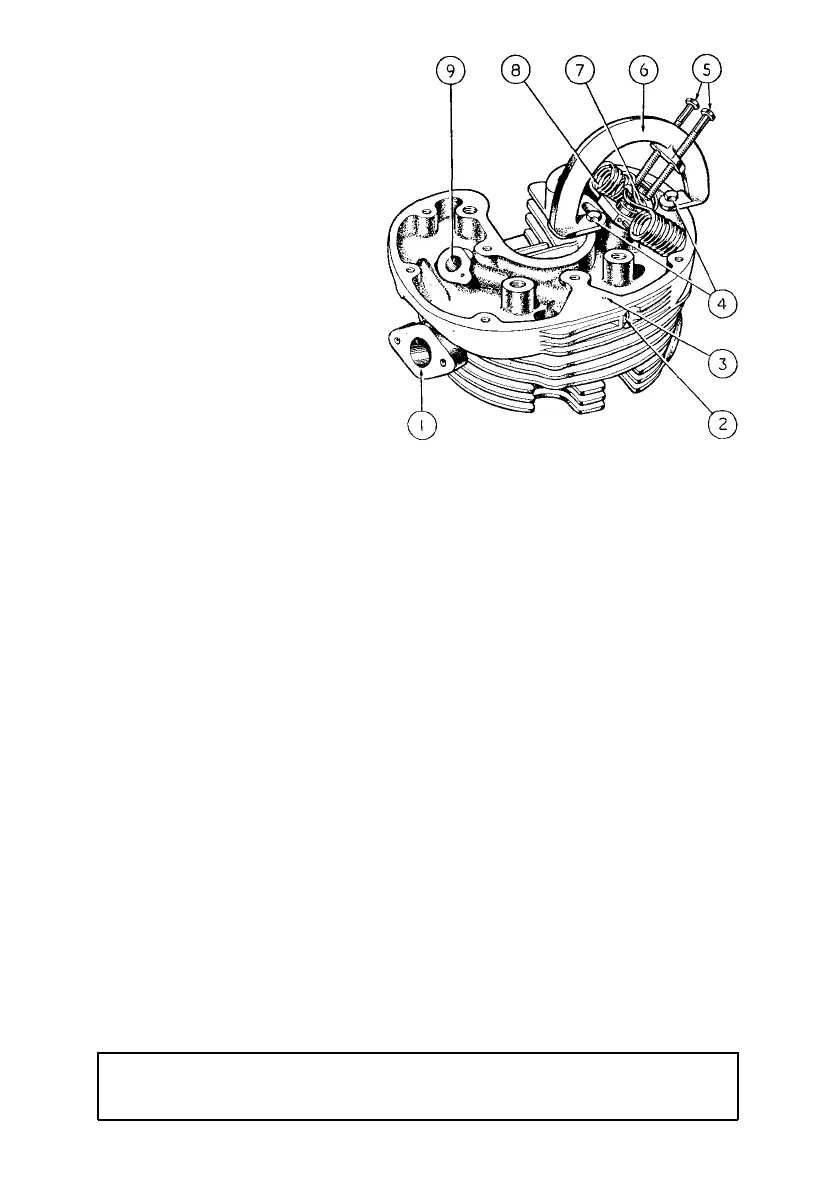

Illustration 9

Showing application of

valve spring compressor

1

2

3

4

INLET VALVE PORT.

ORIFICE FOR SCREW ADJUSTING OIL FEED

TO INLET VALVE.

OIL PASSAGE FROM ROCKER BOX TO

INLET VALVE GUIDE.

BOLTS, 010795 RETAINING V AL VE SPRI NG

COMPRESSO R TO CYLINDER HEAD.

5

6

7

8

9

BOLTS, IMPINGING ON V A LV E SPRING

CO LLA R WH IC H, UPON BEING SCREWED

DO W N , EXPOSE VA LV E C OL LE T THERE-

BY PERMITTING ITS REMOVAL.

BODY OF VA LV E SPRING COMPRESSOR.

COLLAR, RETAINING VALVE SPRINGS.

VALVE SPRINGS.

ORIFICE FOR VALVE GUIDE.

NOTE—The special valve spring compressor tool is not part of the standard tool kit but is

obtained from any of our dealers complete with bolts for attachment (Part

No. 014605.)

It is essential that the collets are correctly located on the valve stems. It will

be observed that the collet has two grooves machined in the bore and those

two grooves must register with the two rings on the valve stem. If fitted so that

only one of the grooves engages the ringed valve stem, damage will almost certainly

result.

On 350 c.c. the inlet valve head is larger in diameter than the exhaust. Therefore

inlet and exhaust valves are not interchangeable and no mistake can be made

when replacing same in the cylinder head.

On 500 c.c. both valve heads are identical in dimensions but are made of different

materials. Therefore, upon removal, valves should be laid aside so that they

may be identified for re-fitting. In case of doubt, see marking " In " or " Ex "

on top of stem above collet grooves.

Loading...

Loading...