IMCP0002 Rev.J 3

1 - Description

1.1 - General description

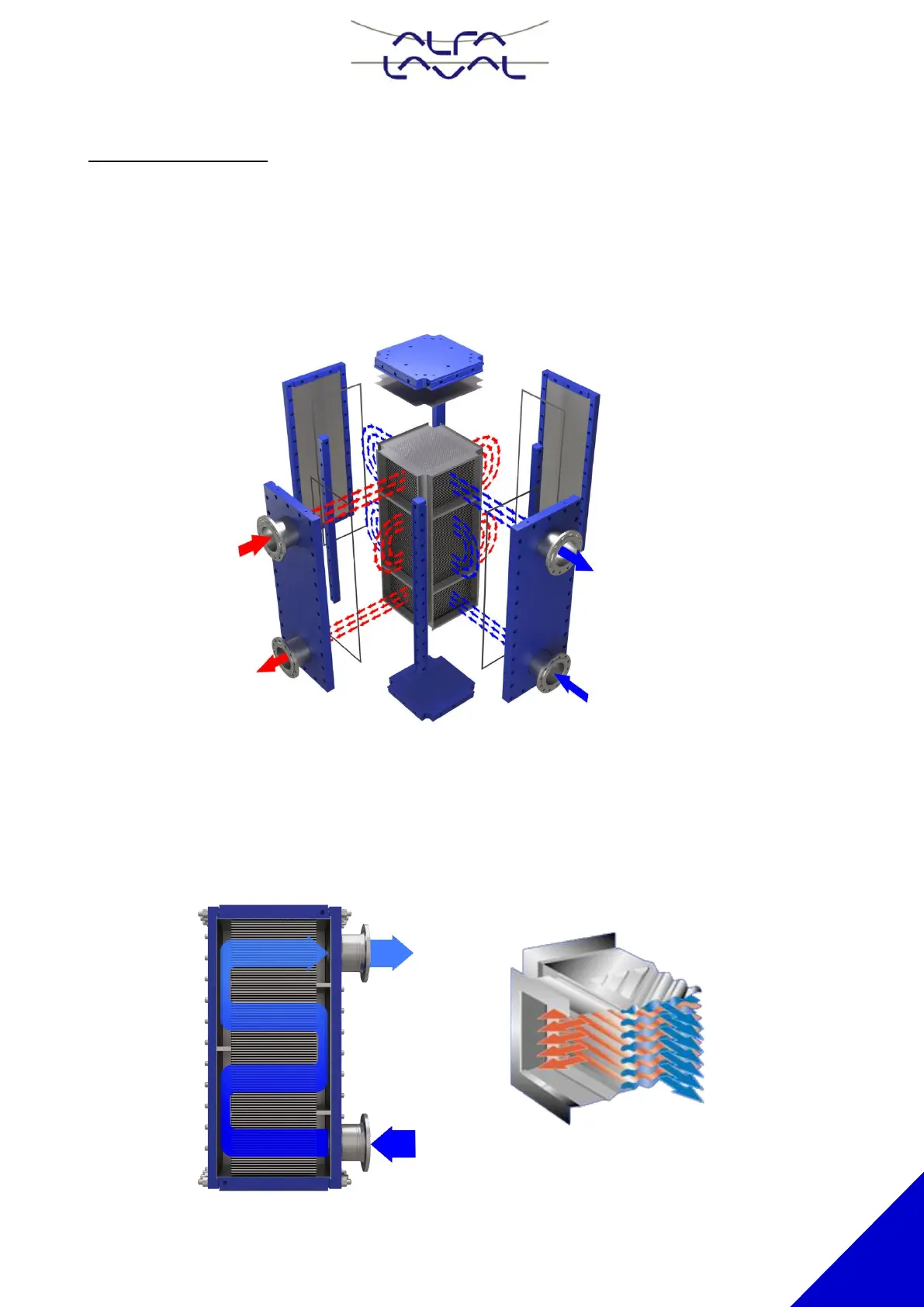

Compabloc is a welded plate heat exchanger without interplate gaskets allowing a large heat transfer area within a very

compact space (low footprint). It is made from stacks of welded plate packs inserted in a rigid rectangular bolted frame

for mechanical strength and the separation of the various circuits. Each circuit can be fitted with a detachable baffle

plate assembly. Only 4 panel gaskets are installed, as indicated on the exploded view Figure 1.

Compabloc is designed and manufactured in accordance with a Pressure Vessel Code (ASME, EN-13445, etc.) and

for defined working conditions. The Design & Manufacture of the Compabloc is made per a Quality System

Management according to ISO 9001.

Figure 1: Compabloc exploded view

Four carbon-steel panels fitted with nozzles enable the connection of the pipework. Optionally, these panels can be

lined with the same material as the plates themselves. The plates, baffle plates, nozzles and panels linings can be

made from stainless steel 316L, Titanium, 254 SMO, Hastelloy, or other pressable and weldable material. The flow can

be directed using baffles (number of passes chosen to maximize heat transfer and minimize fouling).

The bolts of panels are put in place with high temperature lubricant.

Loading...

Loading...