5 Maintenance

5.4.6 Adjusting rotor timing

Step 1

If the rotor timing requires adjustment (and assuming the pump has not yet been re-built), it is important to establish the

cause for the rotors mistiming before proceeding.

To allow timing adjustment ensure that one shaft is able to rotate within the torque locking assembly/element. The other torque

locking assembly/element should be tightened to the recommended torque.

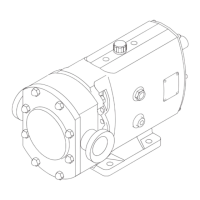

Step 2

Set the rotors (17) to the positions shown with the rotor dimples in

the 6-12 o’clock plane (horizontally ported pumps) or 3-9 o’clock

plane (vertically ported pumps).

For the rotor on the drive shaft the rotor dimple should be aligned

with the drive shaft keyway.

Dimples

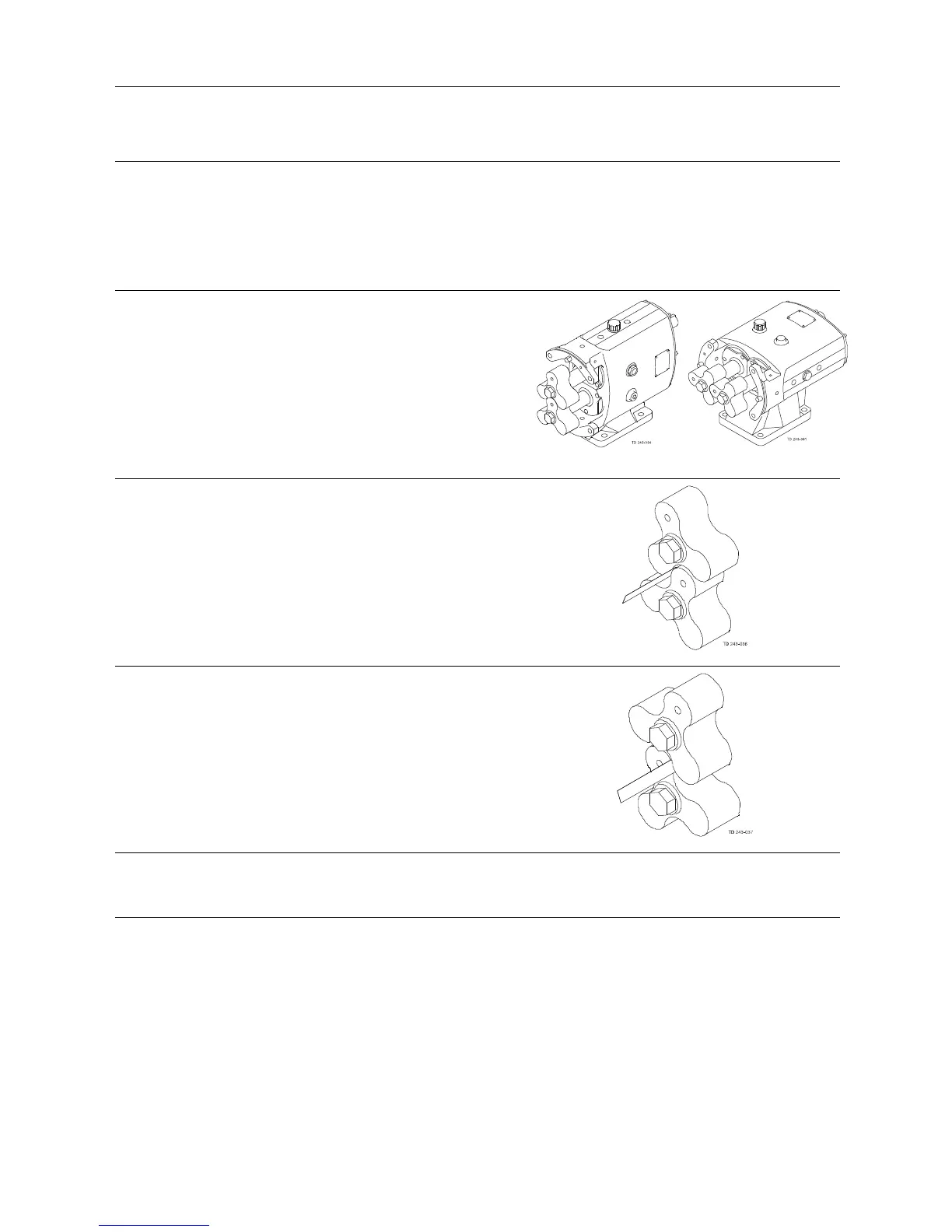

Step 3

Turn the shaft so that the rotors are in the new positions as shown.

Step 4

Using feeler gauges measure between the points indicated,

turning the shaft as required.

Step 5

If the measurement points are unequal tap the rotor which is on the free turning shaft until equal measurement through 6

points is achieved.

Step 6

Tighten the torque locking assemblies or clamp plate screws. Confirm timing is still correct. Remove the rotors.

23

Loading...

Loading...