5 Maintenance

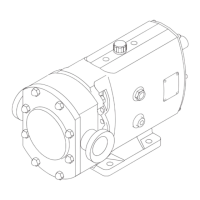

5.4.7 Fitting gearcase cover

Step 1

Clean the gearcase cover bore and remove all gasket material from the face. Press a new lip seal (7) into the cover (5). For

temperatures greater than 130°C (266°F) FPM lip seals are fitted.

Step 2

Apply liquid gasket to the face of the cover where it mates with the gearcase.

Step 3

Smear oil on the inner lip of the lip seal and carefully slide the

coveroverthes

haft ensuring the lip seal is centred and not cut or

damaged. Tighten the screws (6).

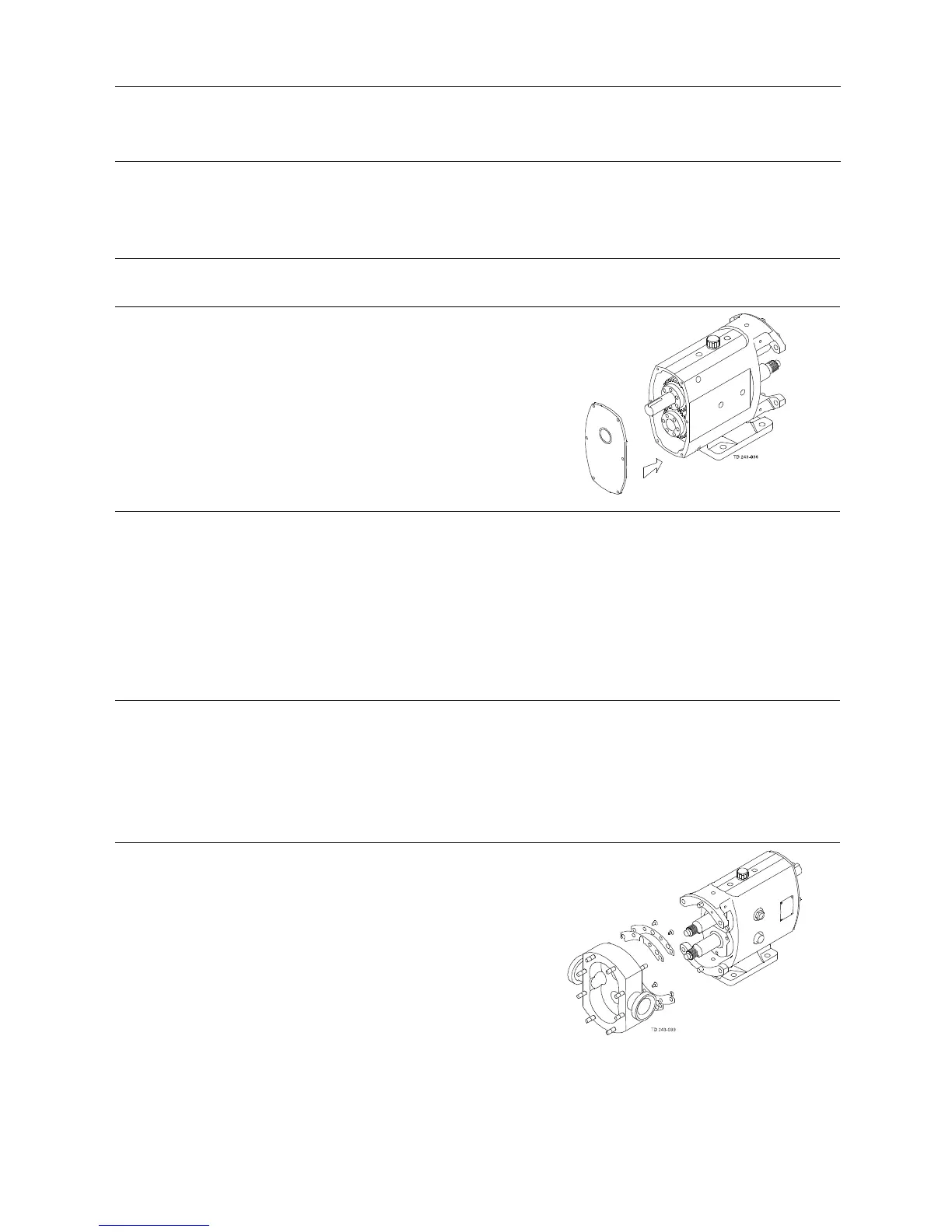

5.4.8 Fitting and shimming rotorcase

The rotorcase may require re-shimming if new components have been fitted. Back clearances must be checked before

operating the pump. See 5.2 Pumphead Clearance information.

NOTE!

Your supplier can advise the correct clearances from the pump serial number. Should they need adjustment follow steps

below. Any incorrect setting of clearances is likely to damage the pump in operation. Plastic shims vary in colour for

different thickness, and are grouped in packs at the top and bottom of the rotorcase held in place by shim retainers. For

temperatures greater than 130°C (266°F) and/or for ATEX stainless steel shims are fitted. Shims can be stacked unequally

providing the clearances are achieved.

Step 1

1. Remove the shim retainers (8A) and fit one of the thinnest shims (8) to top and bottom position.

2. Replace shim retainers and screws (8B).

3. Fit the rotorcase (9) to the gearcase (1), tighten the rotorcase retaining nuts (4) and fit the rotors (17).

The back clearances can now be measured using feeler gauges. The additional shimming required to bring the clearances within

tolerance can be determined, fit additional shims and re-check the clearances.

Step 2

Remove the rotorcase to allow fitting of product seals.

2

4

Loading...

Loading...