Installation English

Plate Heat Exchanger 3

EN

EN

Installation

Requirements

o

e

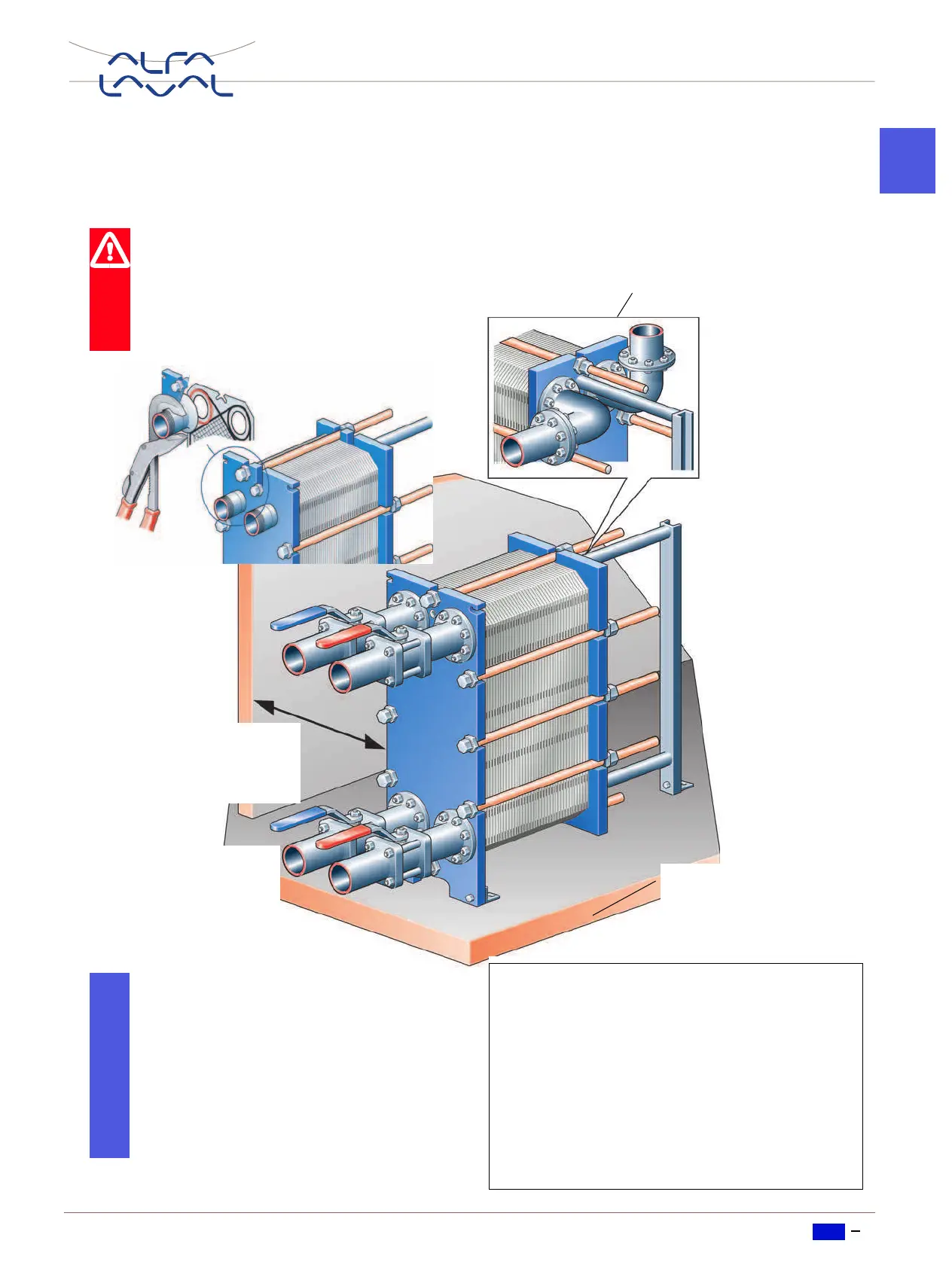

• Before connecting any piping, make sure

all foreign objects have been flushed out of

the system.

• When connecting the pipe system make

sure the pipes do not subject the plate heat

exchanger to stress or strain.

• To avoid water hammer, do not use fast-

closing valves.

Safety valves should be installed according to

current pressure vessel regulations.

If PHE surface temperature is expected to be hot

or cold, the PHE should be isolated.

It is recommended that protective sheets are

used to cover the PHE.

For each model, design pressures and tempera-

tures are marked on the identification plate.

These must not be exceeded.

Pipes

Caution!

Make sure the pipe connections are

locked when working on the piping.

Turning of the connections will dam-

age the gaskets on the end plate

and cause leakage.

Shut-off valves

To be able to open the

heat exchanger, shut-off

valves should be provided

in all connections.

Space

600 mm minimum free space

is needed for lifting plates in

and out.

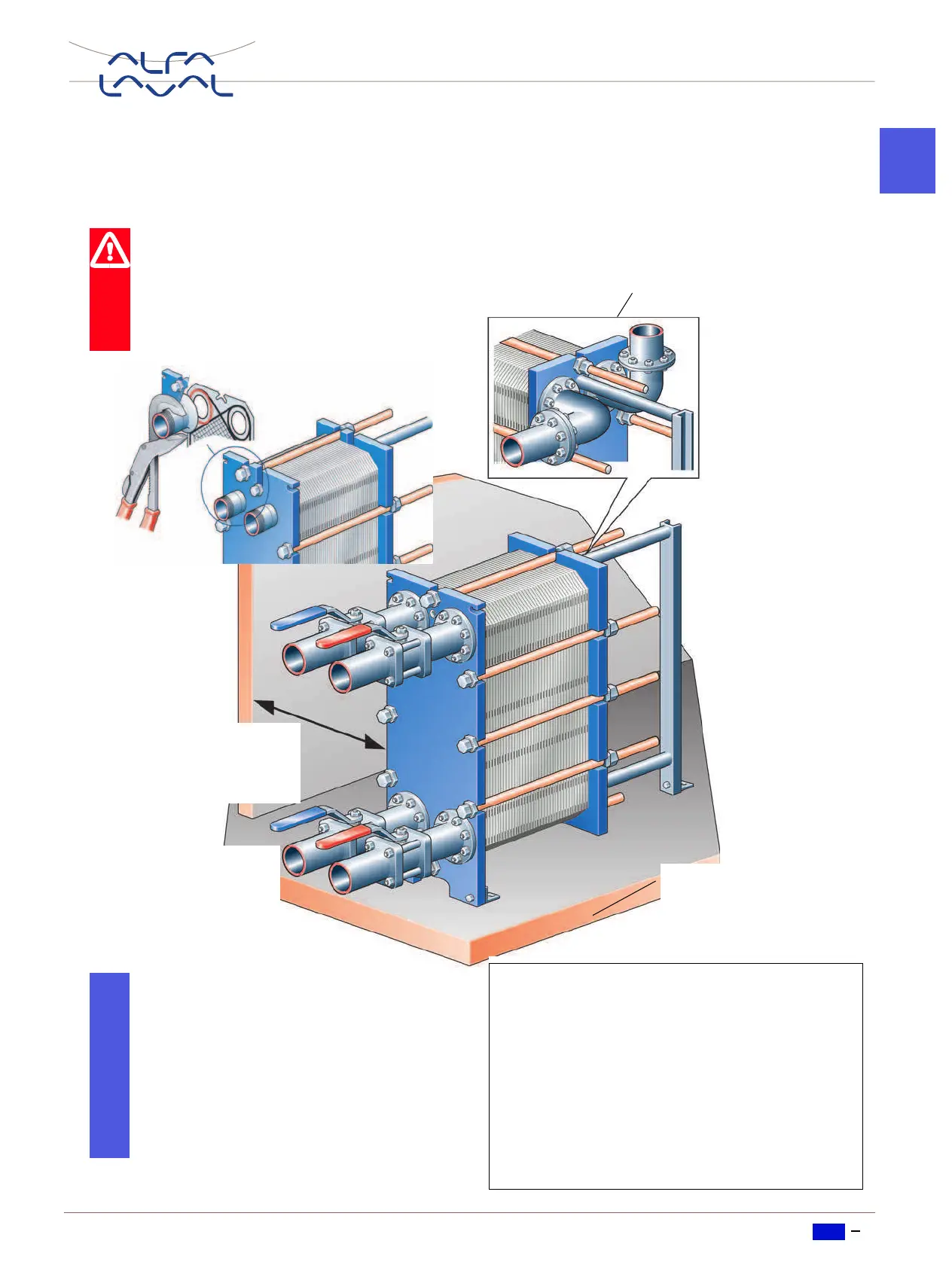

Multi-pass units: Connections on the

pressure plate

It is important that the plate pack has been tight-

ened to the correct measurement (check against

drawing) before the pipe is connected.

Elbow

To make it easier to

disconnect the plate

heat exchanger, an

elbow should be

flanged to the con-

nection in the pres-

sure plate, directed

upwards or side-

ways, and with an-

other flange located

just outside the con-

tour of the heat ex-

changer.

Foundation

Install on a flat foundation

giving enough support to

the frame.

Drip tray

Depending on the

type of fluid in the

PHE and the type of

installation, a drip

tray (drainage box)

may be nesessary

to avoid damages

on personnel and

equipment.

Loading...

Loading...