When you first operate your machine after setup or after an extended period of disuse, run your

machine at 3,000 to 3,500 rpm. for about 10 minutes for the purpose of break-in.

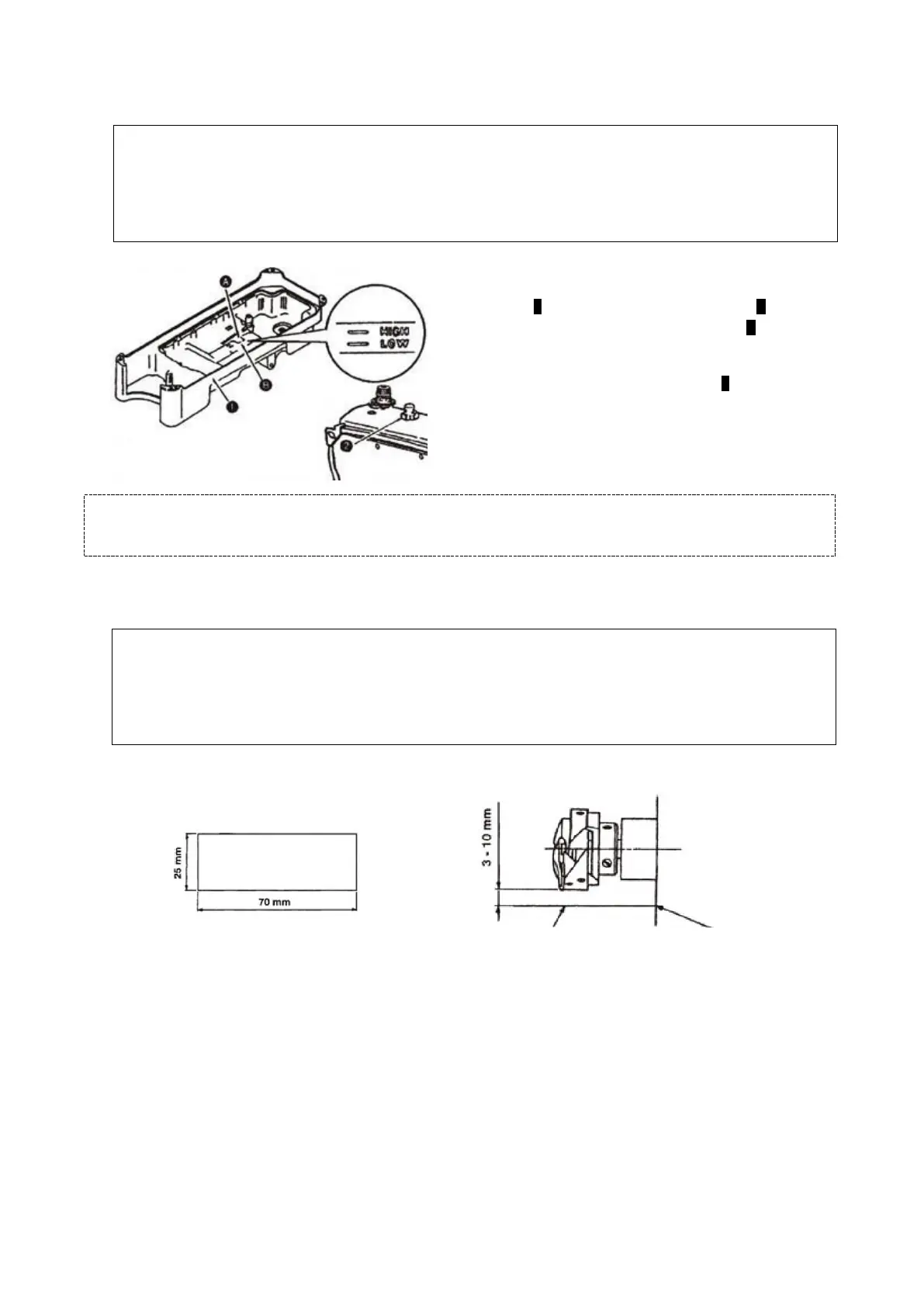

6. LUBRICATION

Information on lubrication

1)

Fill oil pan 1 with Machine Oil up to HIGH mark A.

2)

When the oil level lowers below LOW mark B, refill the oil

pan with the specified oil.

3)

When you operate the machine alter lubrication, you will

see splashing oil through oil sight window 2 if the lubrication

is adequate.

4)

Note that the amount of the splashing oil is unrelated to the

amount of the lubricating oil.

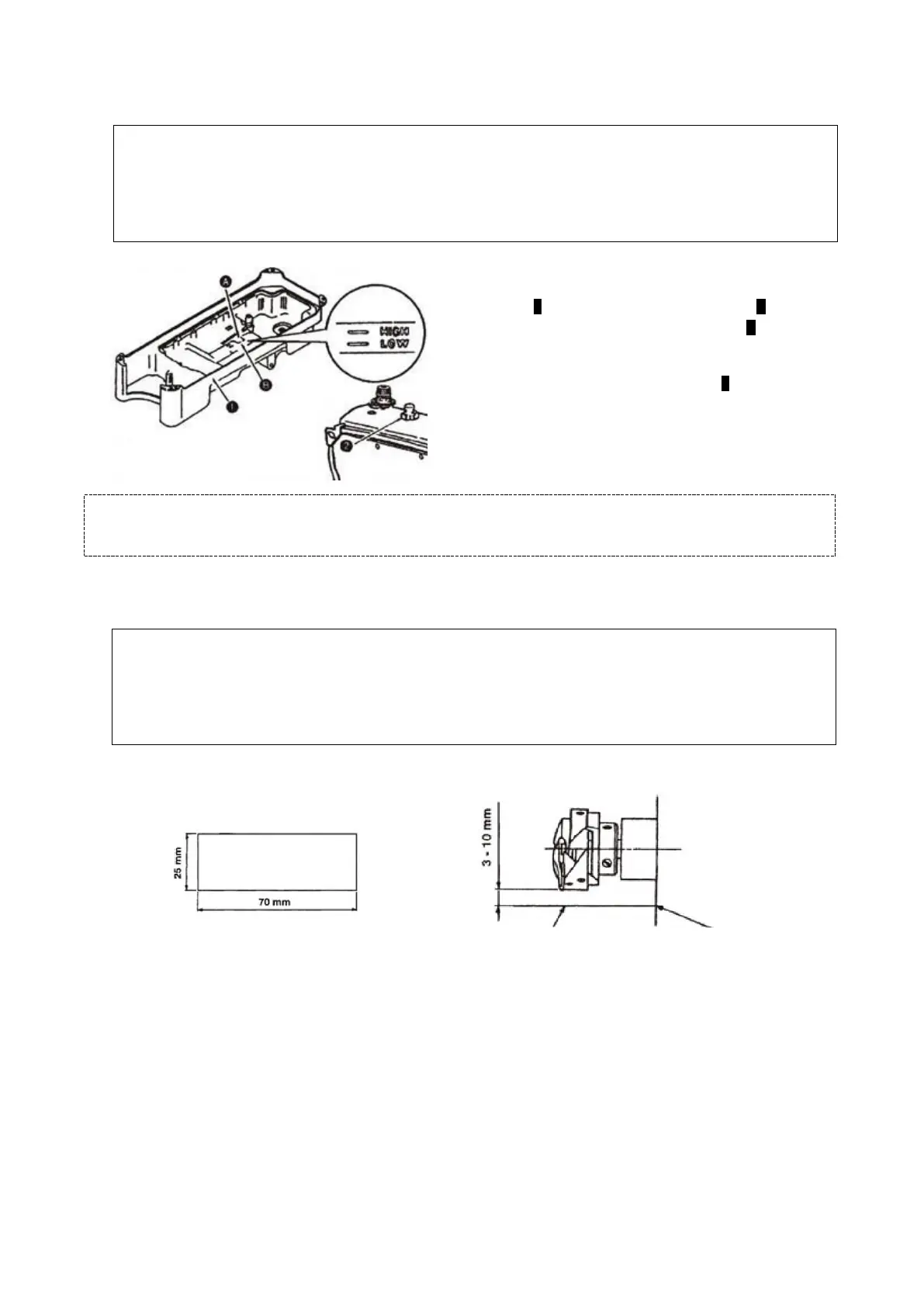

7. AJUSTING THE AMOUNT OF OIL (OIL SPLASHES) IN THE HOOK

1. Amount of oil (oil splashes) confirmation paper 2. Position to confirm the amount of oil (oil splashes)

Oil splashes confirmation paper

Closely fit the paper against the

wall surface of the bed

*

When carrying out the procedure described below in 2, remove the slide plate and take extreme caution not to

allow your fingers to come in contact with the hook.

1)

lf the machine has not been sufficiently warmed up for operation, make the machine run idle for

approximately three minutes (moderate intermittent operation).

2)

Place the amount of oil (oil splashes) confirmation paper under the hook while the sewing machine is in

operation.

3)

Confirm the height of the oil surface in the oil reservoir is within the range between "HIGH" and "LOW".

4)

Confirmation of the amount of oil should be completed in five seconds. (Check the period of time with a watch)

Loading...

Loading...