•

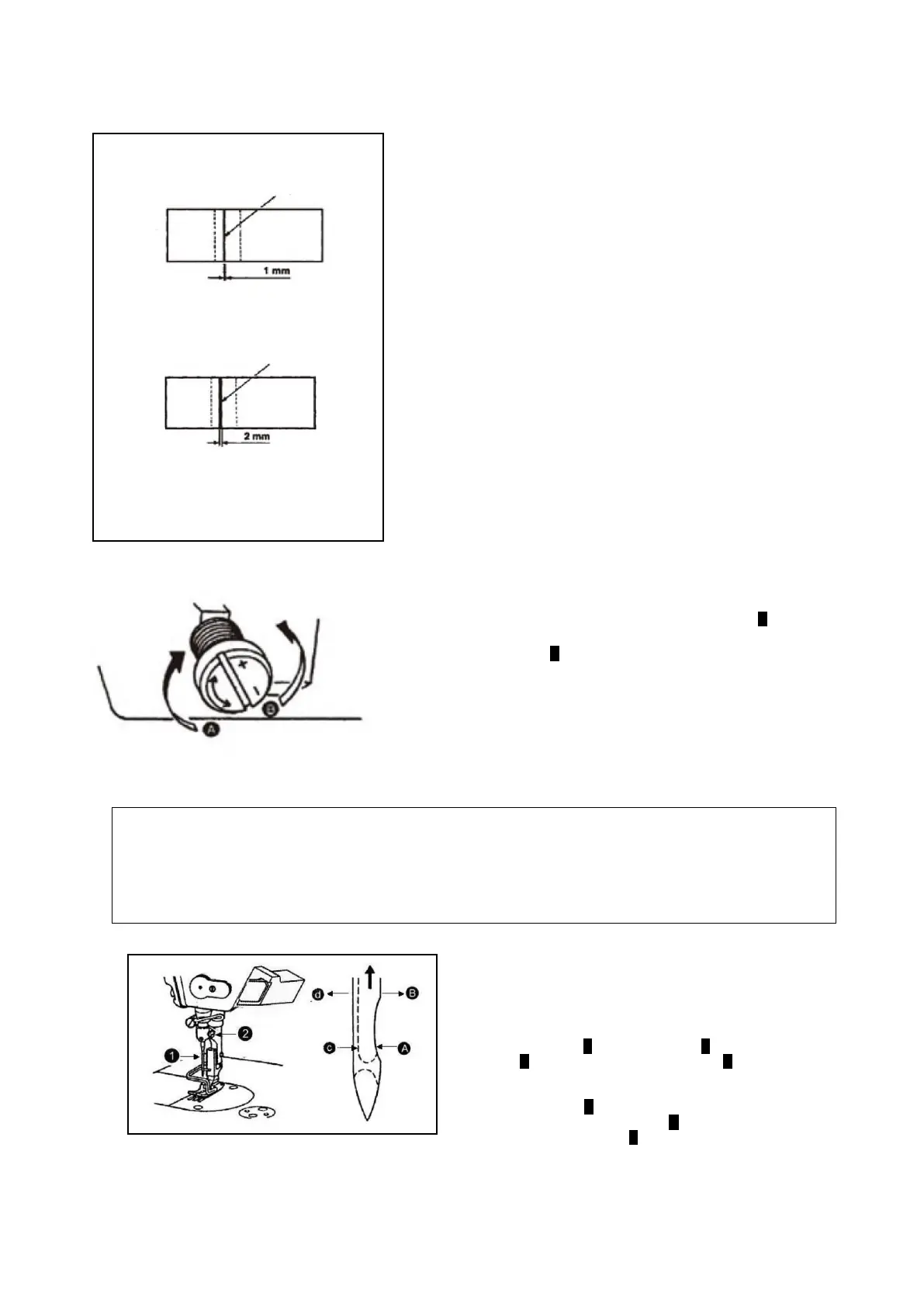

Sample showing the appropriate amount of oil

1)

The amount of oil shown in the samples on the left should be finely

adjusted in accordance with sewing processes. Be careful not to

excessively increase/decrease the amount of oil in the hook. lf the

amount of oil is too small, the hook will be seized (the hook will be

hot). If the amount of oil is too much, the sewing product may be

stained with oil.

2)

Adjust the amount of oil in the hook so that the oil amount (oil

splashes) should not change while checking the oil amount three

times (on the three sheets of paper).

•

Adjusting the amount of oil

1)

Turning the oil amount adjustment screw attached on the hook

driving shaft front bushing in the “+” direction (in direction A), will

increase the amount of oil (oil spots) in the hook. In contrary, in the “-“

direction (in direction B), will decrease it.

2)

After the amount of oil in the hook has been property adjusted with

the oil amount adjustment screw, make the sewing machine run idle

for approximately 30 seconds to check the amount of oil in the hook.

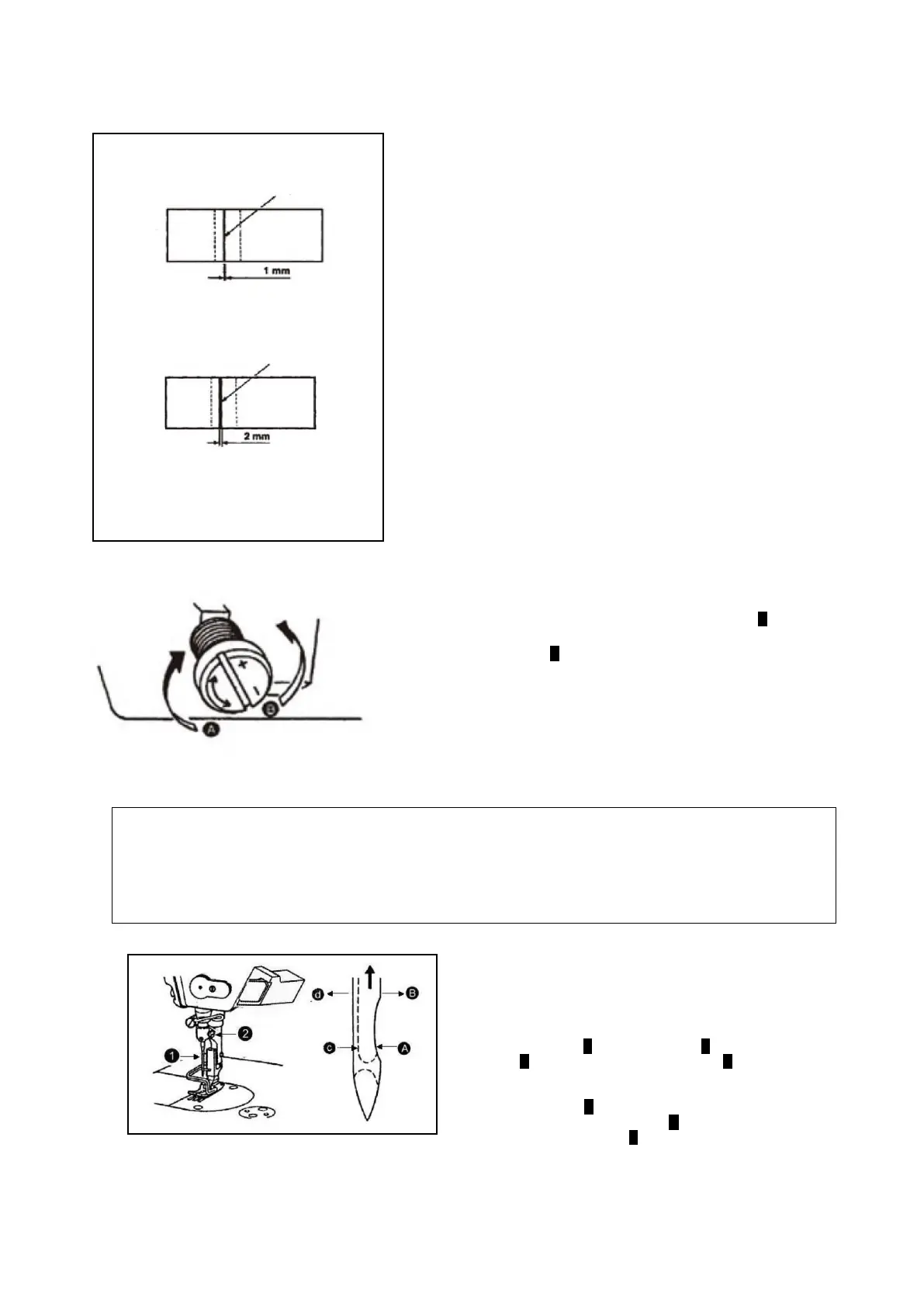

8. ATTACHING THE NEEDLE

Choose a proper needle size according to the

count of thread and the type of sewing material

used.

1)

Turn the handwheel until the needle bar reaches to

the highest point of its stroke.

2)

Loosen screw 2, hold the needle 1 with its intended

part A facing to the right in direction B.

3)

Insert the needle in direction of arrow until it will go

no further.

4)

Tighten screw A.

5)

Make sure the long Groove C of the needle is facing

to the left of direction d.

Loading...

Loading...