4Operation

The valve is adjusted and tested before delivery.

Study the instructions carefully and pay special attention to the warnings!

Pay attention to possible faults.

The items refer to the parts list and service kits section.

4.2 Fault finding and repair

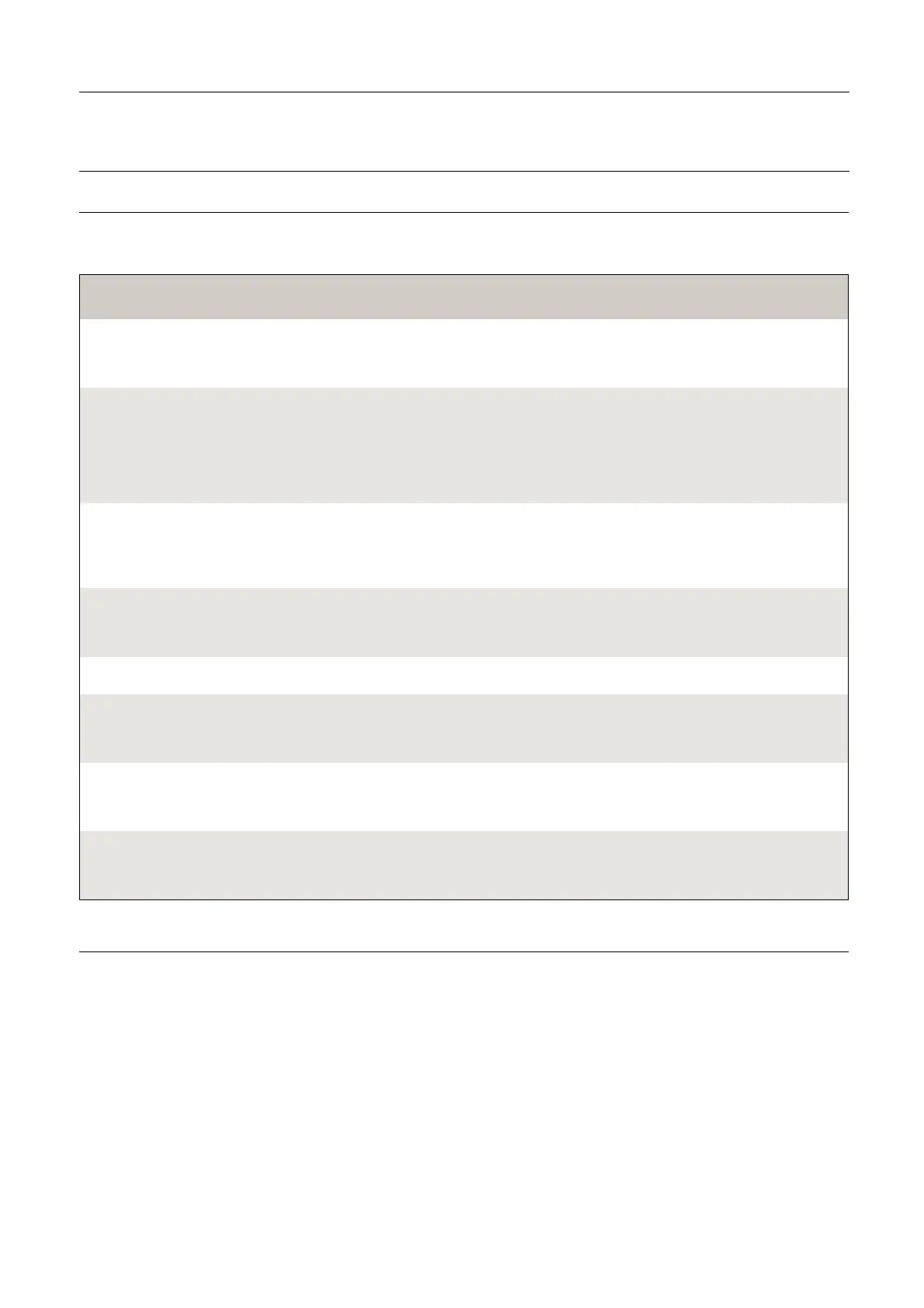

NOTE

Study the maintenance instructions carefully before replacing worn parts.

Problem

Cause/result

Repair

Leakage between sealing element (79)

and lower plug (7

5)

Worn/product affected o-rings/ lip seal

(76/77/78)

- Replace the o-rings/lip seal

- Change rubber grade

- Lubricate correctly

Leakage at the leakage outlet - Particles between valve seats and plug

seals (56/74)

- Worn/product affected plug seal rings

(56/74)

- Plug not assembled correctly

-Removetheparticles

- Check the plug seals

- Replace the plug seals

- Change rubber grade

- Assemble plug, see step 3 section 5.5

Valve assembly

Leakage at sealing element (48)/upper

plug (55)

Worn/product affected o-rings/lip seal

(sizes 38/

39/46/49)

- Replace the o-rings/lip seal

- Change rubber grade

- Clean and if necessary replace guide

ring (45)

Leakage at clamp (64) - Too old/product affected o-rings (76

and 47) (and 52 if clamped valve body)

- Loose clamp (64)

- Replace the o-rings

- Change rubber grade

-Tightentheclamp

CIP leakage Worn o-rings (40/67/71)

Replace the o-rings

Leakage at spindle clamp (43) Damaged o-ring (39) W orn/product

affected lip seal (57) or spray nozzle (58)

- Replace the o-ring

- Replace the plug seals

- Change rubber grade

Lower plug not returning to closed

pos

ition

- Wrong rubber grade

- Wrongly fitted gasket

- Mounted incorrectly (see section 2.3)

- Change rubber grade

- Fit new gasket correctly

- Correct installation

Plug returns with uneven movements

(slip/stick effect)

- Wrong rubber grade

- Wrongly fitted gasket

- Mounted incorrectly (see section 2.3)

- Change rubber grade

- Fit new gasket correctly

- Correct installation

18

Loading...

Loading...