3 Installation

Study the instructions carefully and pay special attention to the warnings!

Thevalvehasendsforweldingasstandard.

Weld carefully/aim at stressless welding to avoid deformation on sealing areas.

Check the valve for smooth operation after welding.

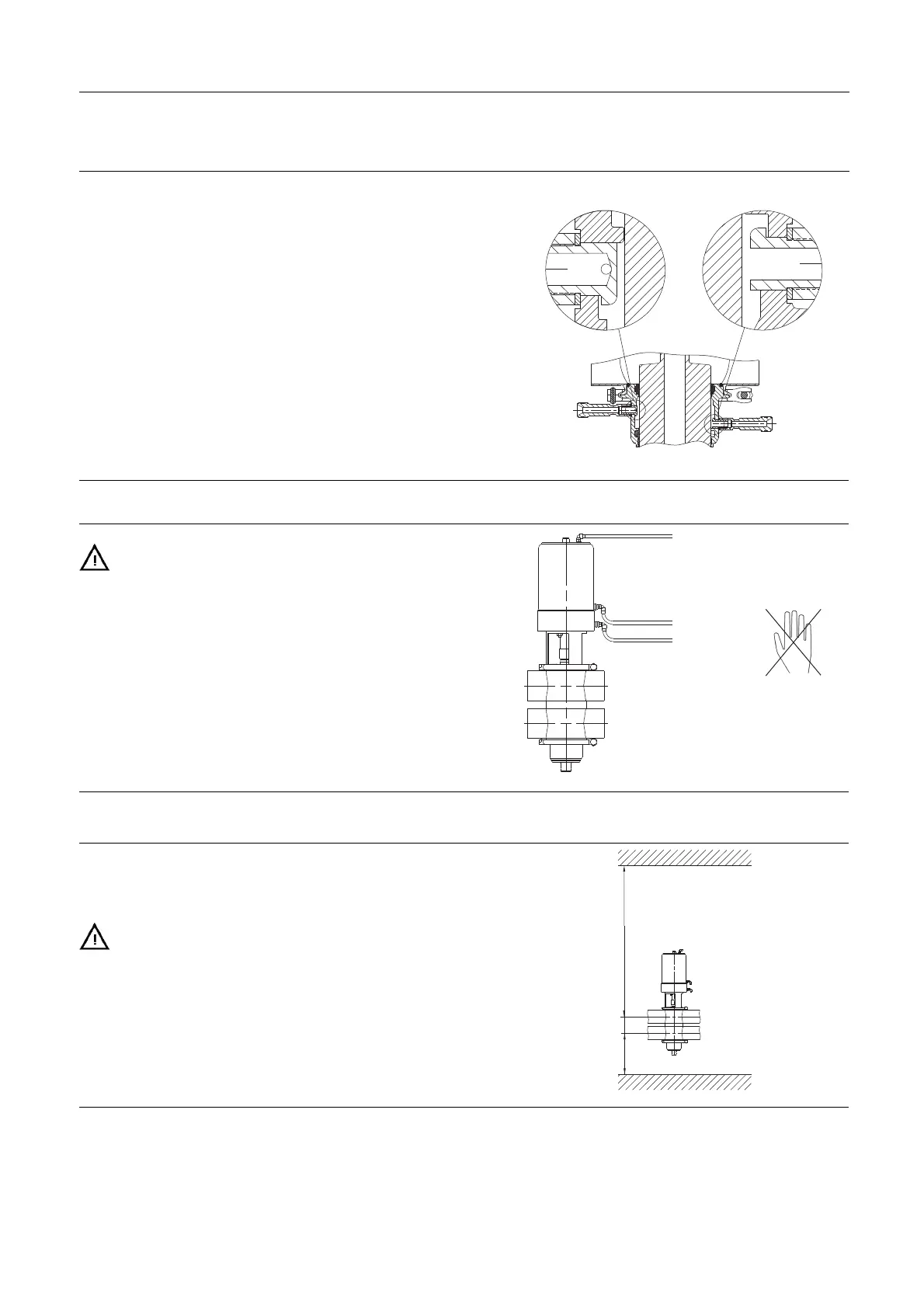

Step 6

It is important to connect CIP inlet to the small inlet nozzle to avoid

built-up pressure in the cleaning chamber.

CIP in CIP out

TD 449-127

Align nozzle e

dges with recess in sealing element.

3.3 Welding

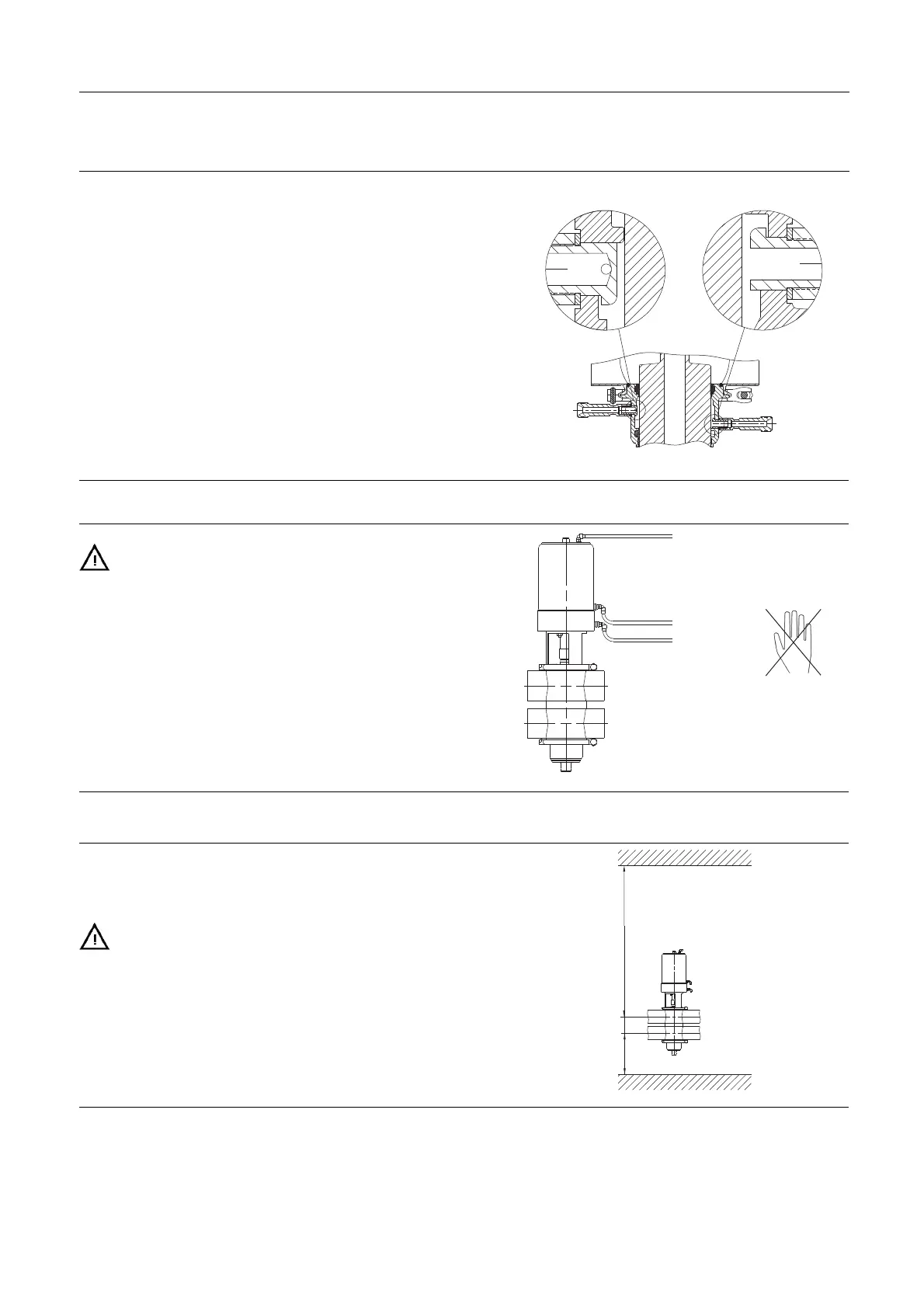

Step 1

Never stick

your fingers through the valve ports if the actuator is

supplied with compressed air.

Cutting danger!

Air

TD 449-325

Step 2

Dismantle the valve in accordance with Step 1 in section 5.2 Dismantling the valve.

Step 3

NOTE

Maintai

n the minimum clearances so that the actuator with the

internal valve parts can be removed - please see later this section!

If there is a risk of foot damage, Alfa Laval recommends to leave

adista

nce of 120 mm (4.7”) below the valve (look at the specific

built-in conditions).

C

B

TD 449-024_1

12

Loading...

Loading...