5 Maintenance

Study the instructions carefully.

The items refer to the parts list and service kits section.

Handle scrap correctly.

Always use Alfa Laval genuine spare parts. Replace seals if necessary.

Repairing of actuator:

- The actuator is maintenance-free but repairable.

- If repair is required, replacing all actuator rubber seals is recommended.

- Lubricate seals with Klüberplex BE31.

- To avoid possible black remains on pos. 1 and 29, Alfa Laval recommends Klüber Paraliq GTE703 (white) for these two

positions.

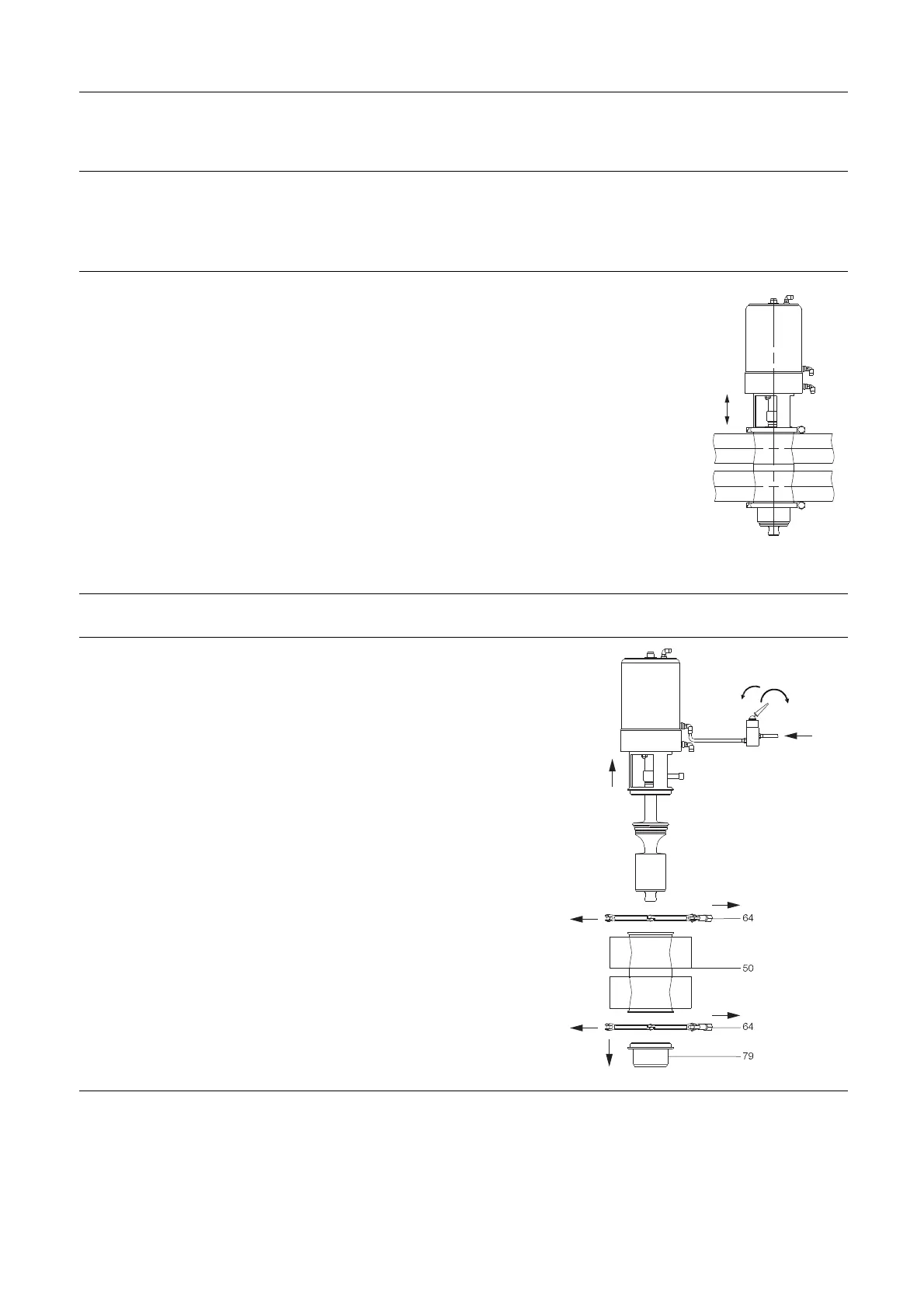

Pre-use check

1. Supply compressed air to AC1, AC2 and AC3 one by one.

2. Operate the valve several times to ensure that it operates

smoothly.

Pay special attention to the warnings!

Operate!

TD 449-045_2

AC3

AC2

AC1

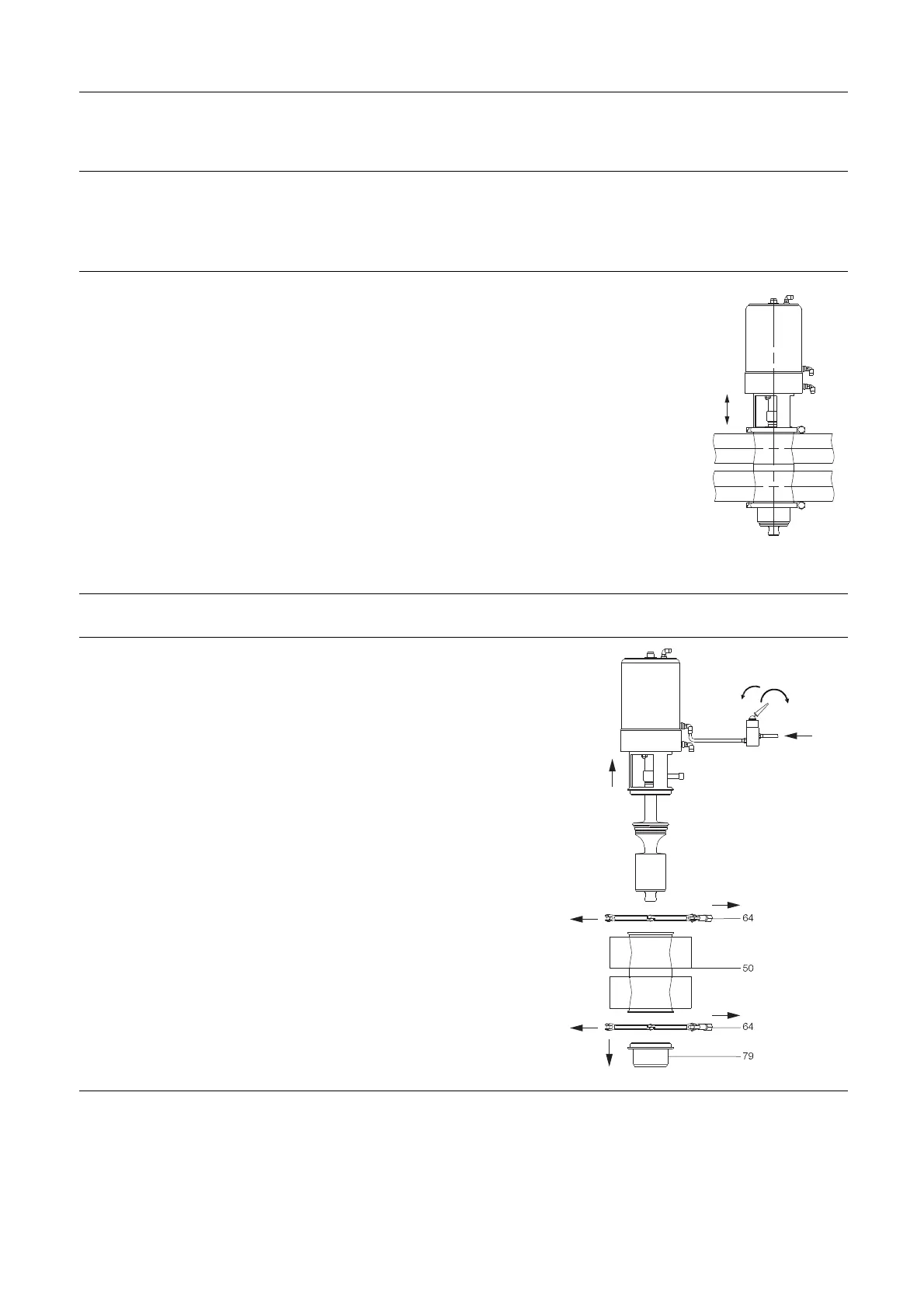

5.2 Dismantling the valve

Step 1

Disassemble valve acc. to illustrations ( 1 to 6 ).

1. Supply compressed air to AC2.

2. Loosen and remove upper clamp (64).

3. Release compressed air.

4. Lift out the actuator together with the internal valve parts from

valve body (50).

5. Loosen and remove lower clamp (64).

6. Take away lower sealing element (79).

OPTION:

If clamped valve body: Loosen and remove clamp and pull upper

(51) and lower (53) valve bodies apart. Pull out o-ring (52).

NOTE

Release compressed air.

1

3

4

2

5

6

A2

A3

A1

TD 449-073_1

25

Loading...

Loading...