5 Maintenance

Study the instructions carefully.

The items refer to the parts list and service kits section.

Handle scrap correctly.

Always use Alfa Laval genuine spare parts. Replace seals if necessary.

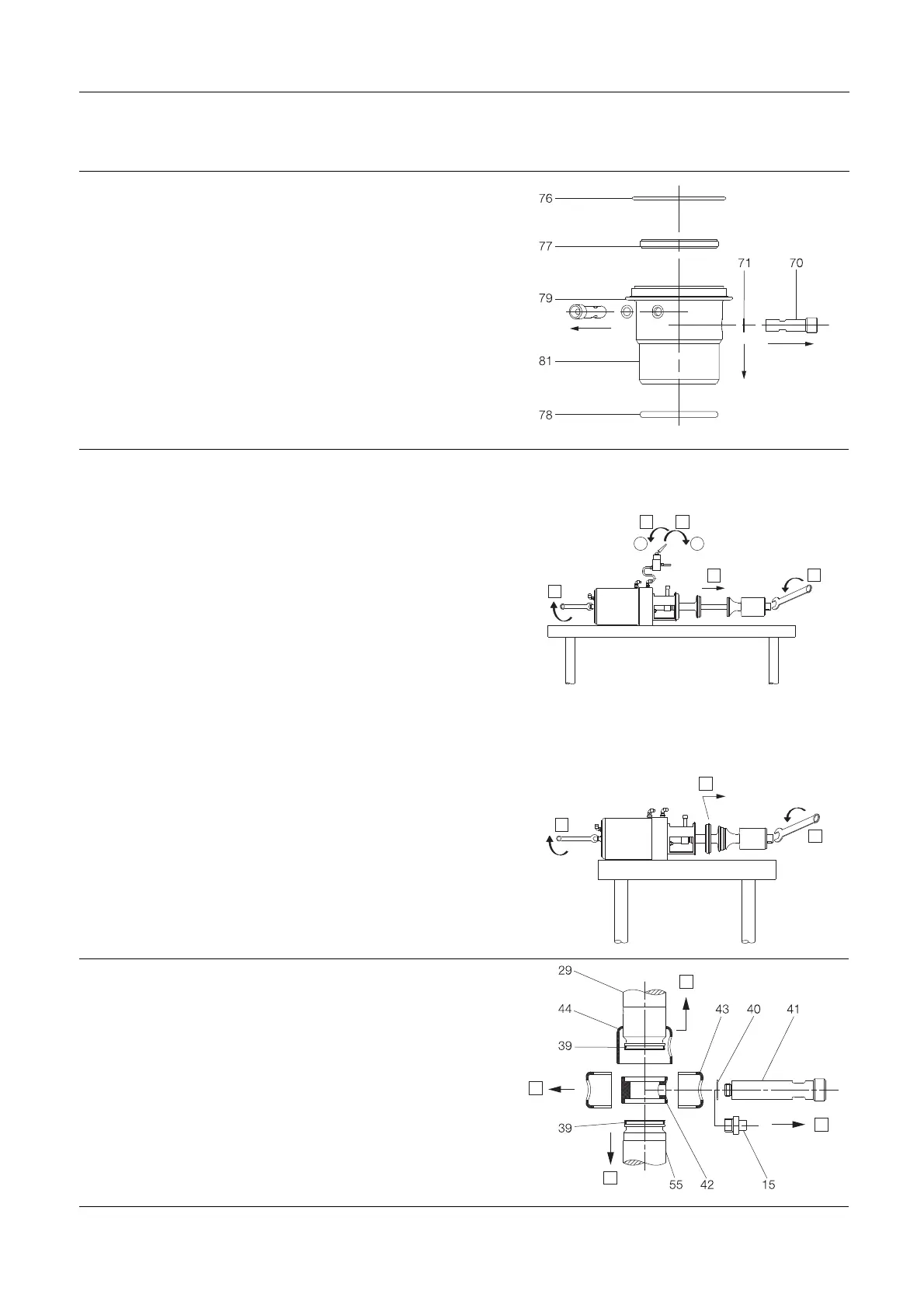

Step 2

Dismantling of low

er sealing element:

1. Pull out o-ring (76

) and lip seal (77).

2. Remove o-ring (78

).

3. Screw out flushin

gtubes(70).

4. Remove o-rings (

71) and nozzles (72 + 73).

TD 449-067_1

Step 3

3A:

If air fitting AC1 is present, supply compressed air and follow

procedure 3A.

1. Supply compressed air for AC1.

2. Loosen lower plug (75) while counterholding upper stem (1).

3. Remove the plug.

4. Release compressed air.

A. On

B. Off

3B:

If no air fitting AC1 is present, follow procedure 3B.

1. Push upper sealing element (48) free of intermediate piece (37).

2. Loosen lower plug while counterholding upper stem.

3. Remove the plug (75).

Replace o-ring (38).

Note: For replacement of seal ring (74), please see section 5.3

Lower plug, replacement of radial seal.

If upper seat lift available

1

3

A

B

4

2

2

TD 449-018_1

If no upper seat lift available

TD 449-074_1

1

2

2

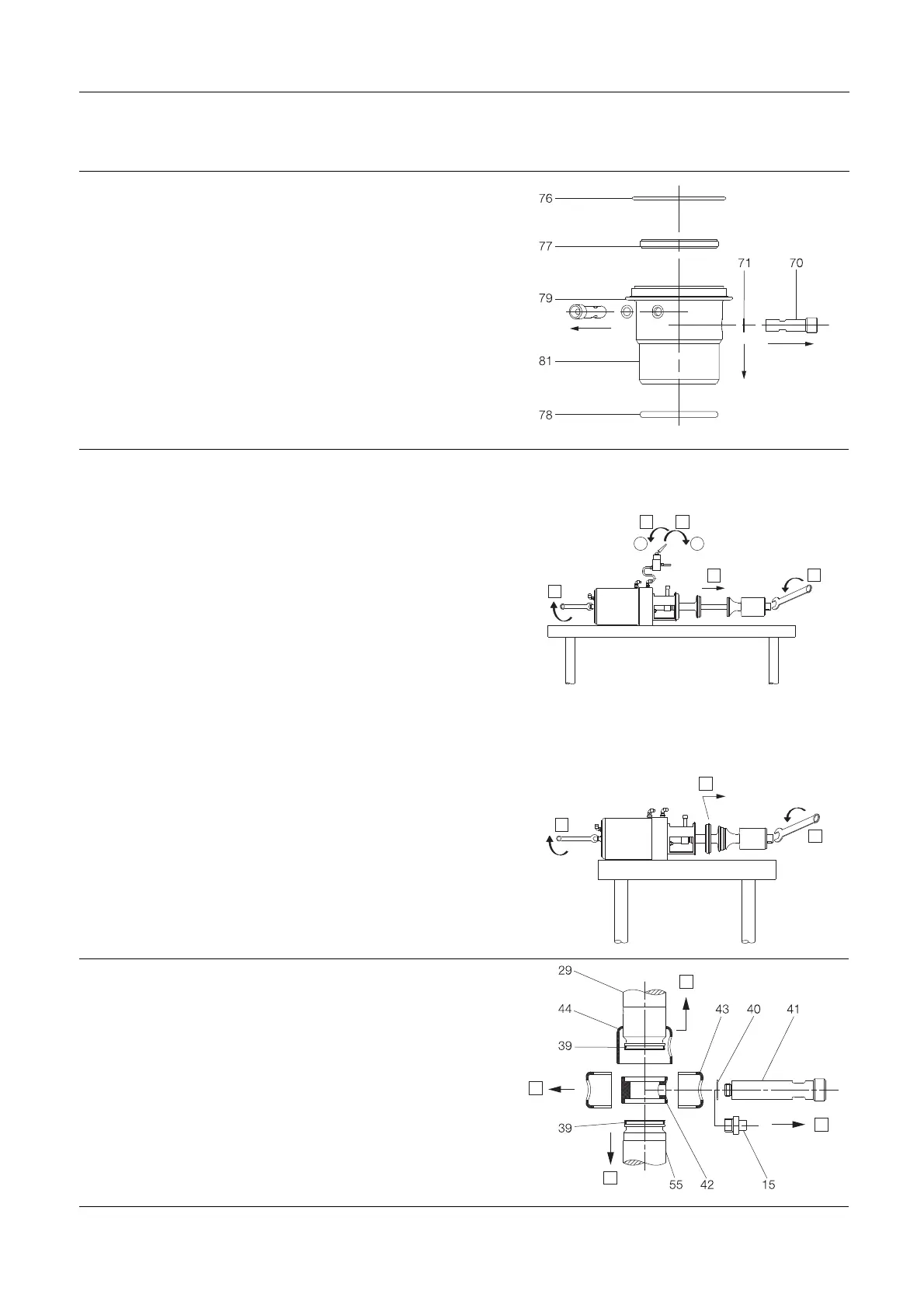

Step 4

Remove coupling system and upper plug according to illustrations

(1to

4).

1. Unsc

rew flushing tube (41) (or plug (15) if no CIP). Remove

o-ri

ng (40).

2. Pull

up lock (44) over piston rod (29).

3. Pul

l away clamps (43) from spindle liner (42).

4. Pul

l out upper plug (55). Make sure spindle liner is free of both

pis

ton rod and upper plug. If external CIP to leakage chamber:

Re

move o-rings (39).

TD 449-065_1

1

3

4

2

26

Loading...

Loading...