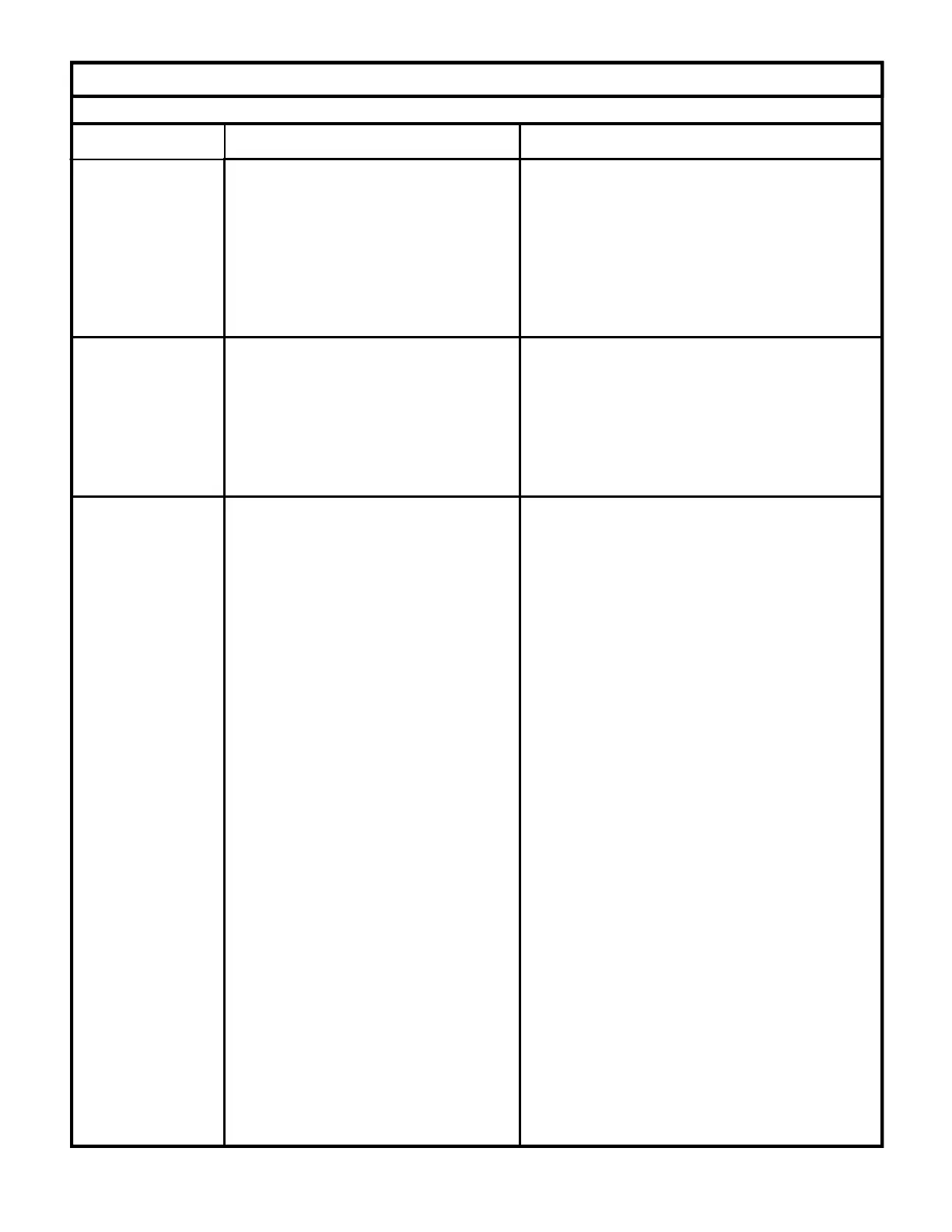

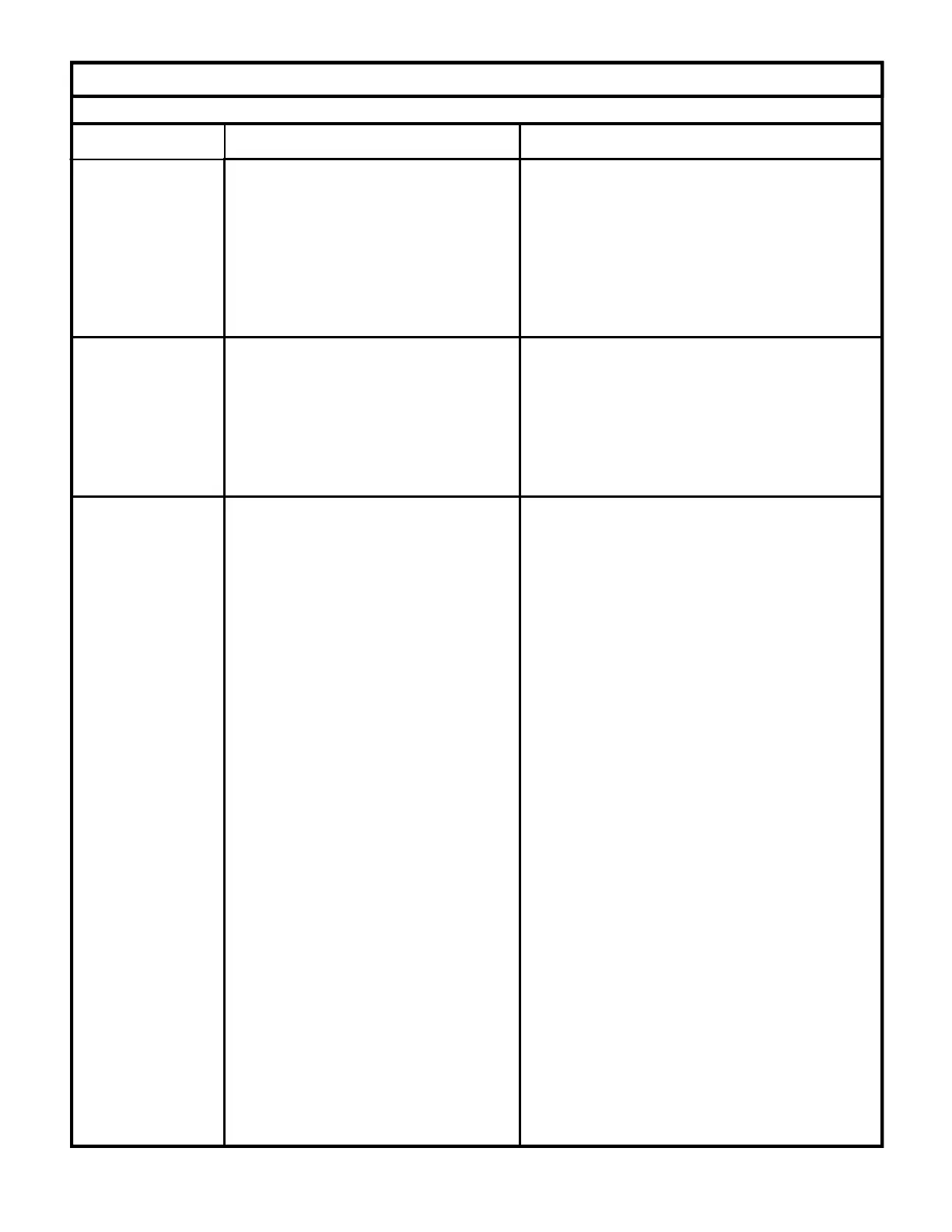

TROUBLE POSSIBLE CAUSE REMEDY

1. Poor Cleaning

Action.

A. Hard water.

B. Low Pressure.

C. Little or no chemical being

drawn.

D. Improper chemical.

E. Improper chemical mixture.

F. Low Discharge Pressure.

A. Connect machine to water softener.

B. See "Low operating pressure"

C. See "Machine will not draw chemical".

D. Obtain proper chemical.

E. Mix chemicals per the label. Follow all

mixing, handling, application, and disposal

instructions.

F. See "Low operating pressure"

2. Machine will

not draw

chemical.

A. No chemical solution.

B. Metering valve not open.

C. Chemical line strainer

clogged.Air leak in chemical line.

D. Metering valve clogged.

E. Restrictor orifice too large or

missing.

A. Replenish supply.

B. Turn metering valve knob to open.

C. Remove screen and clean.

D. Tighten all fittings and hoses for the

chemical line.

E. Disassemble and clean. Install proper size

orifice.

3. Low operating

pressure

A. Insufficient water supply.

B. Incoming water hose too small.

C. Water supply hose too long.

D. Belt slippage.

E. Worn Belt.

F. Spray tip worn or wrong size.

G. Dirty or worn check valves in

water pump.

H. Water supply hose kinked.

I. Inlet filter screen clogged.

J. Motor runs slow.

K. Air leak in inlet plumbing.

L. Defective water pump.

M. Leaking discharge hose.

N. Chemical metering valve open

and sucking air.

O. Defective unloader valve.

P. Inlet ball valve not fully open (if

so equipped)

A. The water supply must meet or exceed the

maximum discharge volume specified in

the PERFORMANCE section, and

minimum water inlet pressure specified

in the GENERAL section of the MODEL

SPECIFCATIONS section.

B. Use larger water supply hose.

C. Use shorter water supply hose.

D. Tighten belt per instructions in

MACHINE MAINTENANCE insert.

E. Replace belt per CLEANER EXPLODED

VIEW.

F. Replace with spray tip specified in the

GENERAL section of MODEL

SPECIFICATIONS.

G. See PUMP TROUBLESHOOTING.

H. Straighten hose.

I. Clean water filter screen or hose inlet

screen.

J. See "Pump engine starts slow or overheats

and stops".

K. Tighten all fittings.

L. See PUMP TROUBLESHOOTING.

M. If a water leak is found, DO NOT

OPERATE THE MACHINE. Disconnect

the power and replace hose.

N. Resupply chemical, place soap screen in

water, or shut off metering valve.

O. Repair or replace unloader valve.

P. Open inlet ball valve completely.

(Handle parallel w/valve body).

ELECTRIC MOTOR DRIVEN COLD WATER CLEANERS

CLEANER TROUBLESHOOTING

Supersedes 08-09-02 Z08-02784

01-16-04 Z08-02784

9

Loading...

Loading...