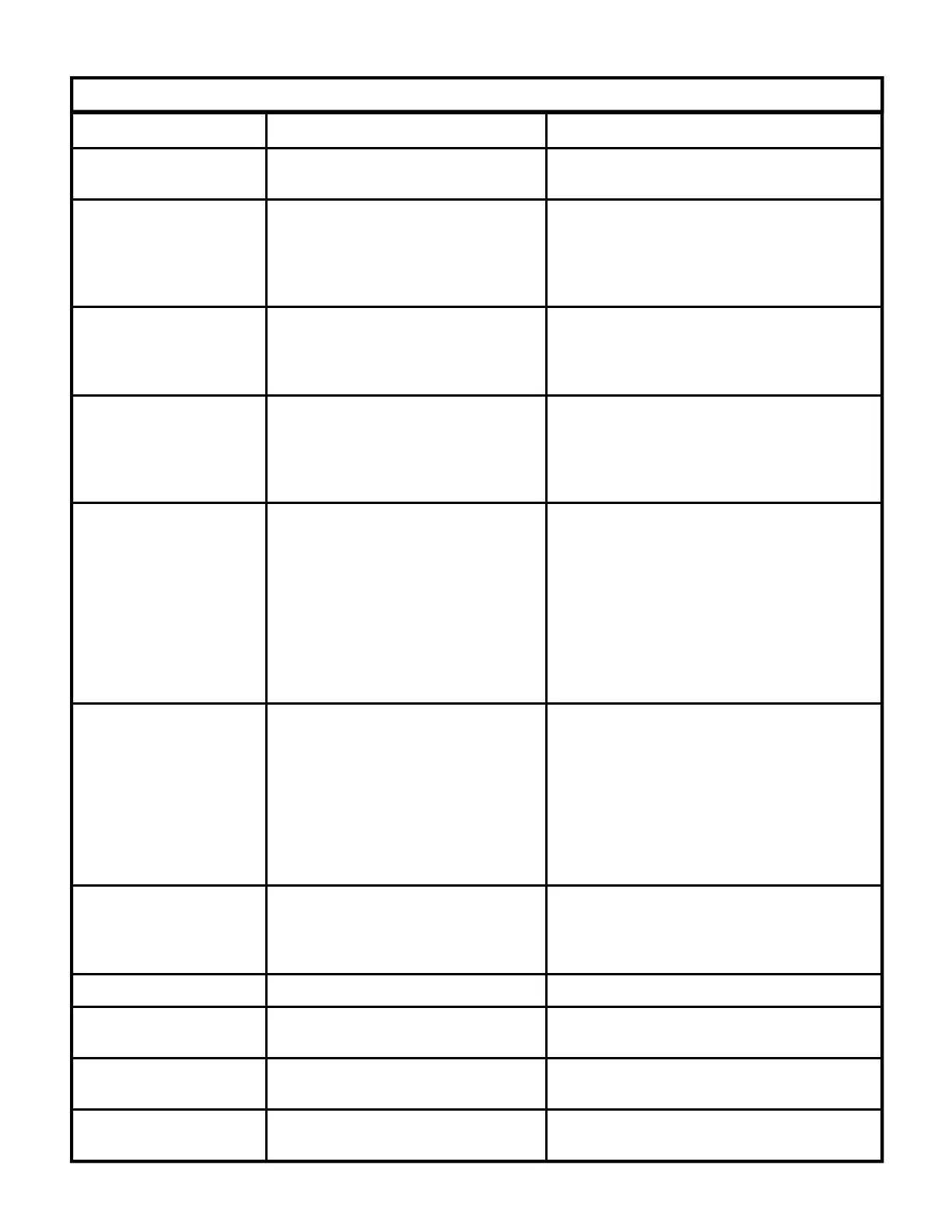

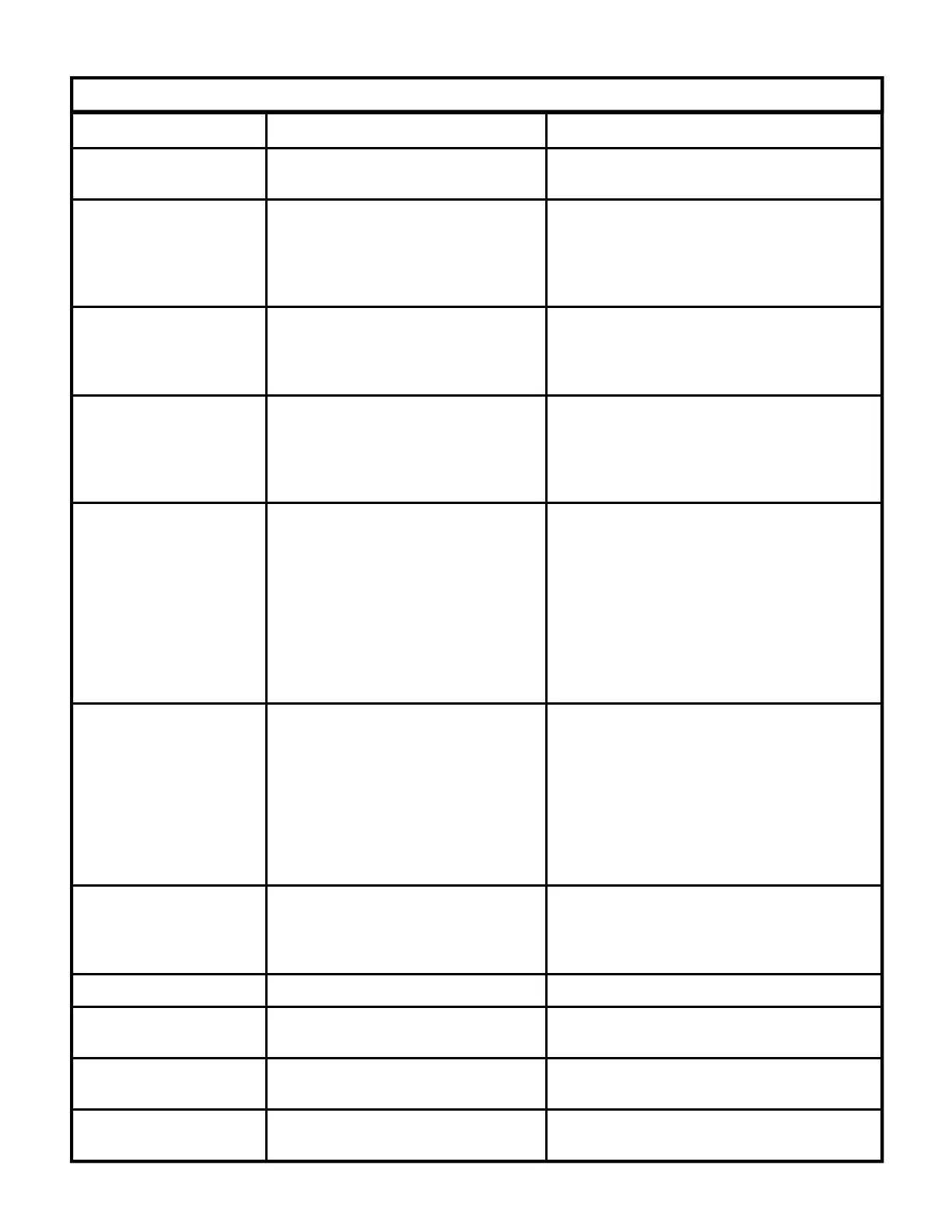

PUMP TROUBLESHOOTING

08-27-03 Z08-00195A

ECN-02981

TROUBLE POSSIBLE CAUSE REMEDY

9. Dirty or worn check

valves.

A. Normal wear.

B. Debris

A. Remove and replace.

B. Check for lack of water inlet screens.

10. Presence of metal

particles during oil

change.

A. Failure of internal component.

B. New pump.

A. Remove and disassemble to find

probable cause.

B. New pumps have machine fillings and

debris and should be drained and

refilled per PUMP SPECIFICATIONS.

11. Water leakage from

under head.

A. Worn packing.

B. Cracked/scored plunger.

C. Failure of plunger retainer

o-ring.

A. Install new packing.

B. Remove and replace plunger.

C. Remove and replace plunger retainer

o-ring.

12. Loud knocking

noise

in pump

A. Pulley loose on crankshaft.

B. Defective bearing.

C. Worn connecting rod.

D. Worn crankshaft.

E. Worn crosshead.

A. Check key and tighten set screw.

B. Remove and replace bearing.

C. Remove and replace connecting rod.

D. Remove and replace crankshaft.

E. Remove and replace crosshead.

13. Frequent or

premature failure of

the packing

A. Scored, damaged, or worn

plunger.

B. Overpressure to inlet manifold.

C. Abrasive material in the fluid

being pumped.

D. Excessive pressure and or

temperature of fluid being

pumped.

E. Over pressure of pumps.

F. Running pump dry.

A. Remove and replace plungers.

B. Reduce inlet pressure.

C. Install proper filtration on pump inlet

pumping.

D. Check pressures and fluid inlet

temperature; be sure they are within

specified range.

E. Reduce pressure.

F. Do not run pump without water.

14. Low Pressure A. Dirty or worn check valves.

B. Worn packing.

C. Belt slipping.

D. Improperly sized spray tip or

nozzle.

E. Inlet filter screen is clogged.

F. Pitted valves.

A. Clean/Replace check valves.

B. Remove and replace packing.

C. See BELT TENSION in MACHINE

MAINTENANCE.

D. See MACHINE SPECIFICATIONS for

specified spray tip or nozzle.

E. Clean inlet filter screen.

F. See VALVE SERVICE in PUMP

MAINTENANCE.

15. Erratic pressure:

pump runs rough

A. Dirty or worn check valves.

B. Foreign particles in valve

assemblies.

C. High inlet water temperature

A. Clean/Replace check valves.

A. Clean/Replace check valves.

C. See temperature in PUMP

SPECIFICATIONS.

16. Excessive vibration A. Dirty or worn check valves A. See "Dirty or worn check valves"

17. Scored plungers A. Abrasive material in fluid being

pumped.

A. Install proper filtration on pump inlet

plumbing

18. Pitted plungers A. Cavitation A. Decrease inlet water temperature

and/or increase inlet water pressure.

19. Cavitation A. High inlet fluid

temperatureLow inlet pressure.

A. Lower inlet fluid temperature.Raise

inlet fluid pressure.

Loading...

Loading...