Rockwell Automation Publication 520-QS001A-EN-E - March 2014 25

PowerFlex 520-Series Adjustable Frequency AC Drive

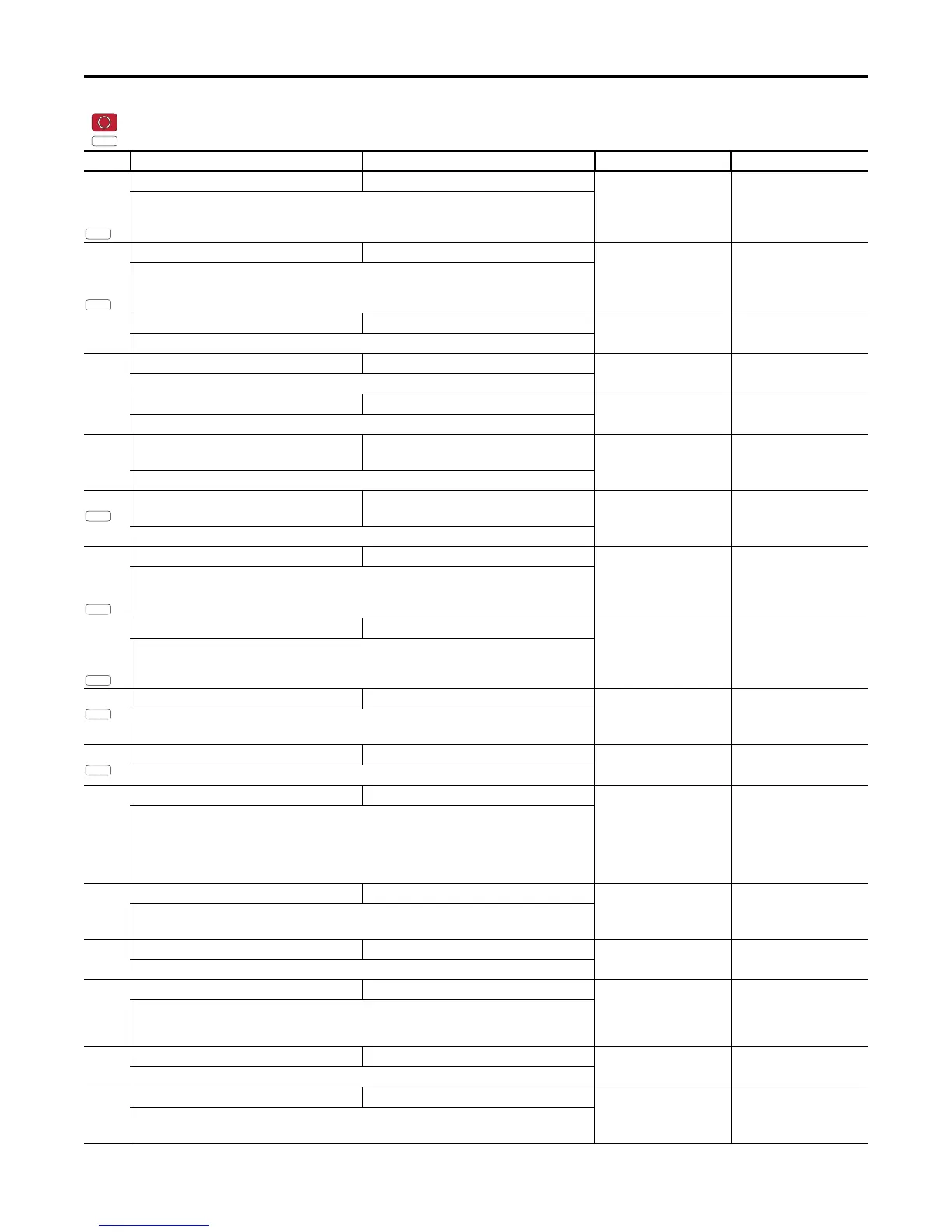

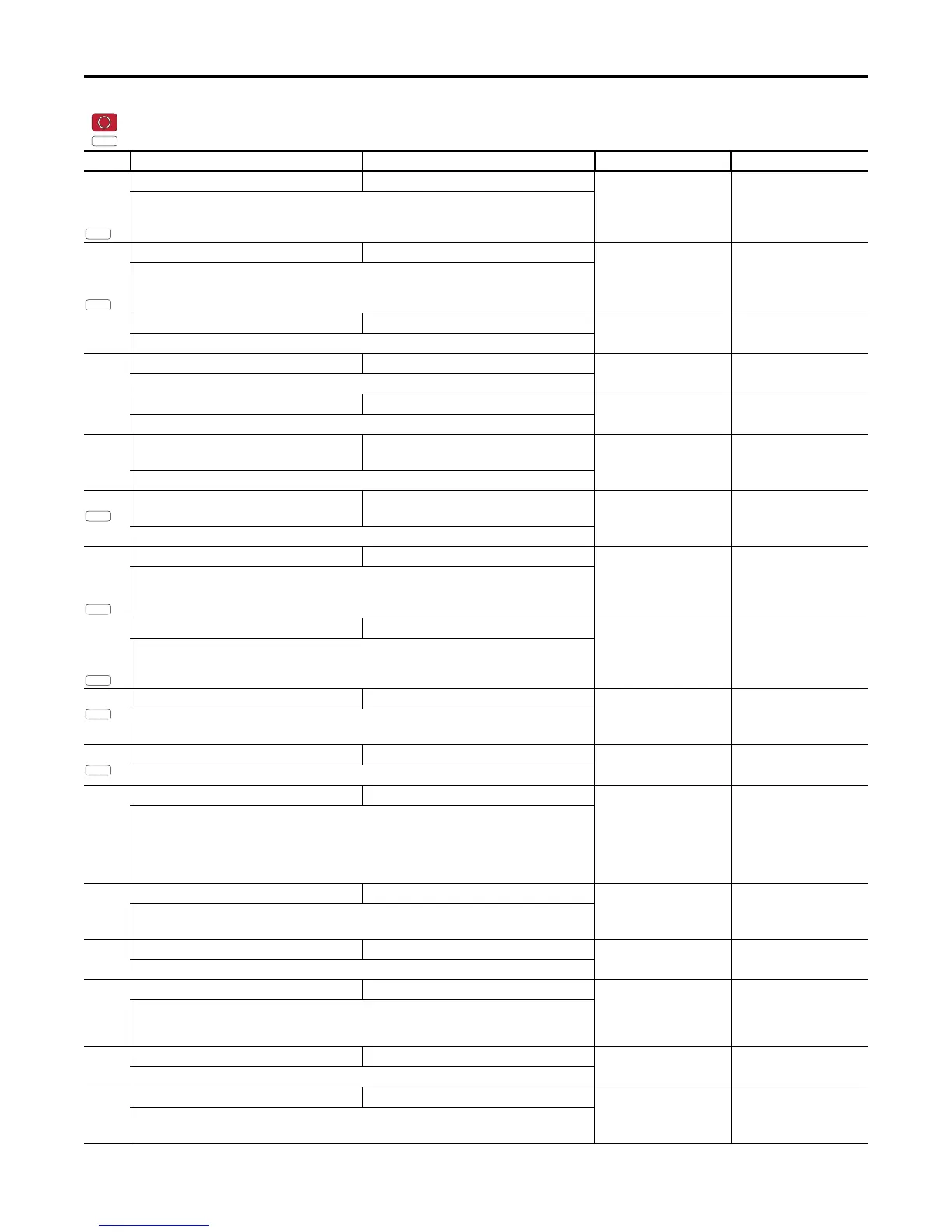

A466

A478

[PID x Preload] 0.0/500.0 Hz 0.1 Hz 0.0 Hz

Sets the value used to preload the integral component on start or enable.

A467

A479

[PID x Invert Err] 0/1 0 = “Normal”

1 = “Inverted”

0 = “Normal”

Changes the sign of the PID error.

A481 [Process Disp Lo] 0.00/99.99 0.01 0.00

Sets the value displayed in b010 [Process Display] when the drive is running at P043 [Minimum Freq].

A482 [Process Disp Hi] 0.00/99.99 0.01 0.00

Sets the value displayed in b010 [Process Display] when the drive is running at P044 [Maximum Freq].

A483 [Testpoint Sel] 0/FFFF 1 400

Used by Rockwell Automation field service personnel.

A484 [Current Limit 1] 0.0/Drive Rated Amps x 1.5 (Normal Duty); Drive

Rated Amps x 1.8 (Heavy Duty)

0.1 A Drive Rated Amps x 1.1

(Normal Duty); Drive Rated

Amps x 1.5 (Heavy Duty)

Maximum output current allowed before current limiting occurs.

A485 [Current Limit 2] 0.0/Drive Rated Amps x 1.5 (Normal Duty); Drive

Rated Amps x 1.8 (Heavy Duty)

0.1 A Drive Rated Amps x 1.1

Maximum output current allowed before current limiting occurs.

A486

A488

[Shear Pinx Level] 0.0/(Drive Rated Amps x 2) 0.1 A 0.0 A (Disabled)

Sets the value of current at which the shear pin fault occurs after the time set in A487, A489 [Shear Pin x

Time]. Setting the value at 0.0 A disables this function.

A487

A489

[Shear Pin x Time] 0.00/30.00 s 0.01 s 0.00 s

Sets the continuous time the drive must be at or above the value set in A486, A488 [Shear Pinx Level]

before a shear pin fault occurs.

A490 [Load Loss Level] 0.0/Drive Rated Amps 0.1 A 0.0 A

Provides a software trip (Load Loss fault) when the current drops below this level for the time specified in

A491 [Load Loss Time].

A491 [Load Loss Time] 0/9999 s 1 s 0 s

Sets the required time for the current to be below A490 [Load Loss Level] before a Load Loss fault occurs

A492 [Stall Fault Time] 0/5 0 = “60 Seconds”

1 = “120 Seconds”

2 = “240 Seconds”

3 = “360 Seconds”

4 = “480 Seconds”

5 = “Flt Disabled”

0 = “60 Seconds”

Sets the time that the drive remains in stall mode before a fault is issued.

A493 [Motor OL Select] 0/2 0 = “No Derate”

1 = “Min. Derate”

2 = “Max. Derate”

0 = “No Derate”

Drive provides Class 10 overload protection. Settings 0...2 select the derating factor for the I

2

t overload

function.

A494 [Motor OL Ret] 0/1 0 = “Reset”

1 = “Save”

0 = “Reset

Selects whether the motor overload counter is saved on power-down or reset on power-up.

A495 [Drive OL Mode] 0/3 0 = “Disabled”

1 = “Reduce CLim”

2 = “Reduce PWM”

3 = “Both-PWM 1st”

3 = “Both-PWM 1st”

Determines how the drive handles overload conditions that would otherwise cause the drive to fault.

A496 [IR Voltage Drop] 0.0/600.0VAC 0.1VAC Based on Drive Rating

Value of volts dropped across the resistance of the motor stator (autotune) for induction motor.

A497 [Flux Current Ref] 0.00/(Drive Rated Amps x 1.4) 0.01 A Based on Drive Rating

This is the current necessary for full motor flux. The value should be set to the full speed no-load current of

the motor.

= Stop drive before changing this parameter.

= Parameter is specific to PowerFlex 525 drives only.

No. Parameter Min/Max Display/Options Default

PF 525

Loading...

Loading...