5

Wire Rope Selection

Each winch model can have a variety of wire rope sizes

installed by the user. The maximum wire rope size is shown

on the nameplate. When a larger diameter wire rope is

used, the length of wire rope installed on the drum will be

shorter. In some situations, the winch can create a tension

in the wire rope that is greater than the strength of the

wire rope. The user must be careful to select a wire rope

that has enough strength and length for the job.

During operation of the winch, the

operator must know or estimate the line

pull and make sure that the line pull is

within the capacity of the winch and the

specifi cations of the wire rope installed

on the drum. A broken wire rope under

high tension can return suddenly in the

direction of the winch and cause injury

and damage.

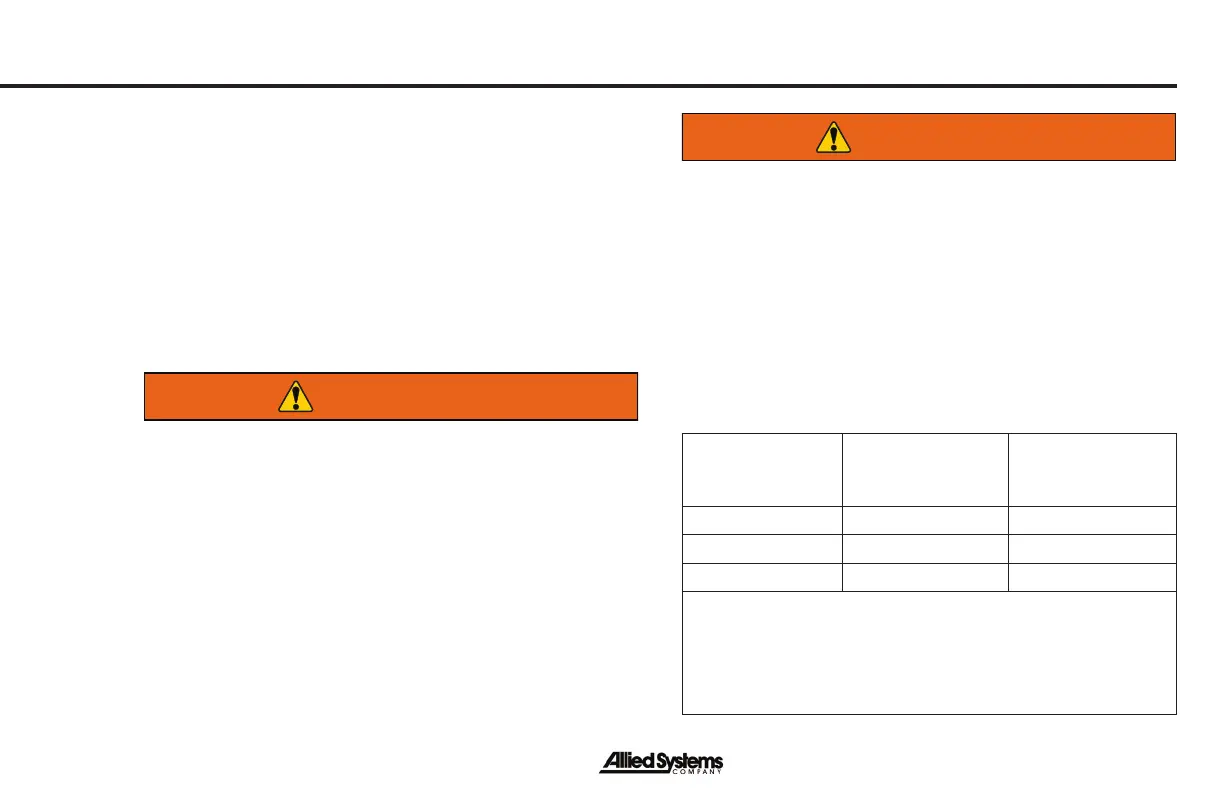

Figure 3 - Drum Line Approximate Capacities

Wire Rope

Diameter

Capacity for

10 in (254 mm)

Drum Diameter

Capacity for

7 in (178 mm)

Drum Diameter

3/4 in (19 mm) 399 ft (121 m) 425 ft (129 m)

7/8 in (22 mm) 287 ft (87 m) 305 ft (93 m)

1.0 in (25 mm)* 223 ft (68 m) 237 ft (72 m)

Notes:

1. Loosely or unevenly spooled line will change capacities.

2. Use fl exible wire rope with independent wire rope center.

3. Ferule size: ø2.0 inches, 2 1/4 inches long.

* If your winch is equipped with the optional arch, the largest wire

rope diameter approved for use is 7/8 inch.

General

The wire rope may disengage from the

ferrule pocket if there is a load on the wire

rope with fewer than 3 complete wraps on

the drum. This will cause a loss of load and

possible injury. When spooling cable from

the drum, it is very diffi cult for the operator

to know when nearing the end of the wire

rope. It is recommended that the last 5

wraps of wire be painted a contrasting

color to alert the operator that the end of

the usable wire rope has been reached.

Loading...

Loading...